Welding wire and method thereby to perform gas welding repair operations on bell frogs and switch rails gas welding repair operation

A technology of bell fork and welding wire, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems that welding wire cannot realize bell fork, point rail welding repair, can not be welded for bel fork, air holes, cracks, etc. , to achieve short maintenance time, prolong service life and save material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A welding wire whose material composition is as follows:

[0016] Carbon: 0.48%

[0017] Silicon: 0.16%

[0018] Manganese: 0.70%

[0019] Chromium: 0.8%

[0020] Nickel: 0.32%

[0021] Copper: ≤0.24%

[0022] Phosphorus: ≤0.04%

[0023] Sulfur: ≤0.04%

[0024] The rest is Fe.

Embodiment 3

[0026] A welding wire whose material composition is as follows:

[0027] Carbon: 0.52%

[0028] Silicon: 0.25%

[0029] Manganese: 0.82%

[0030] Chromium: 0.86%

[0031] Nickel: 0.22%

[0032] Copper: 0.22%

[0033] Phosphorus: 0.02%

[0034] Sulfur: 0.02%

[0035] The rest is Fe.

[0036] Embodiment three

[0037] A welding wire whose material composition is as follows:

[0038] Carbon: 0.58%

[0039] Silicon: 0.27%

[0040] Manganese: 1.00%

[0041] Chromium: 1.08%

[0042] Nickel: ≤0.32%

[0043] Copper: ≤0.24%

[0044] Phosphorus: ≤0.04%

[0045] Sulfur: ≤0.04%

[0046] The rest is Fe.

[0047] Embodiment of the method for gas welding and repairing operation of bell branch and point rail with welding wire

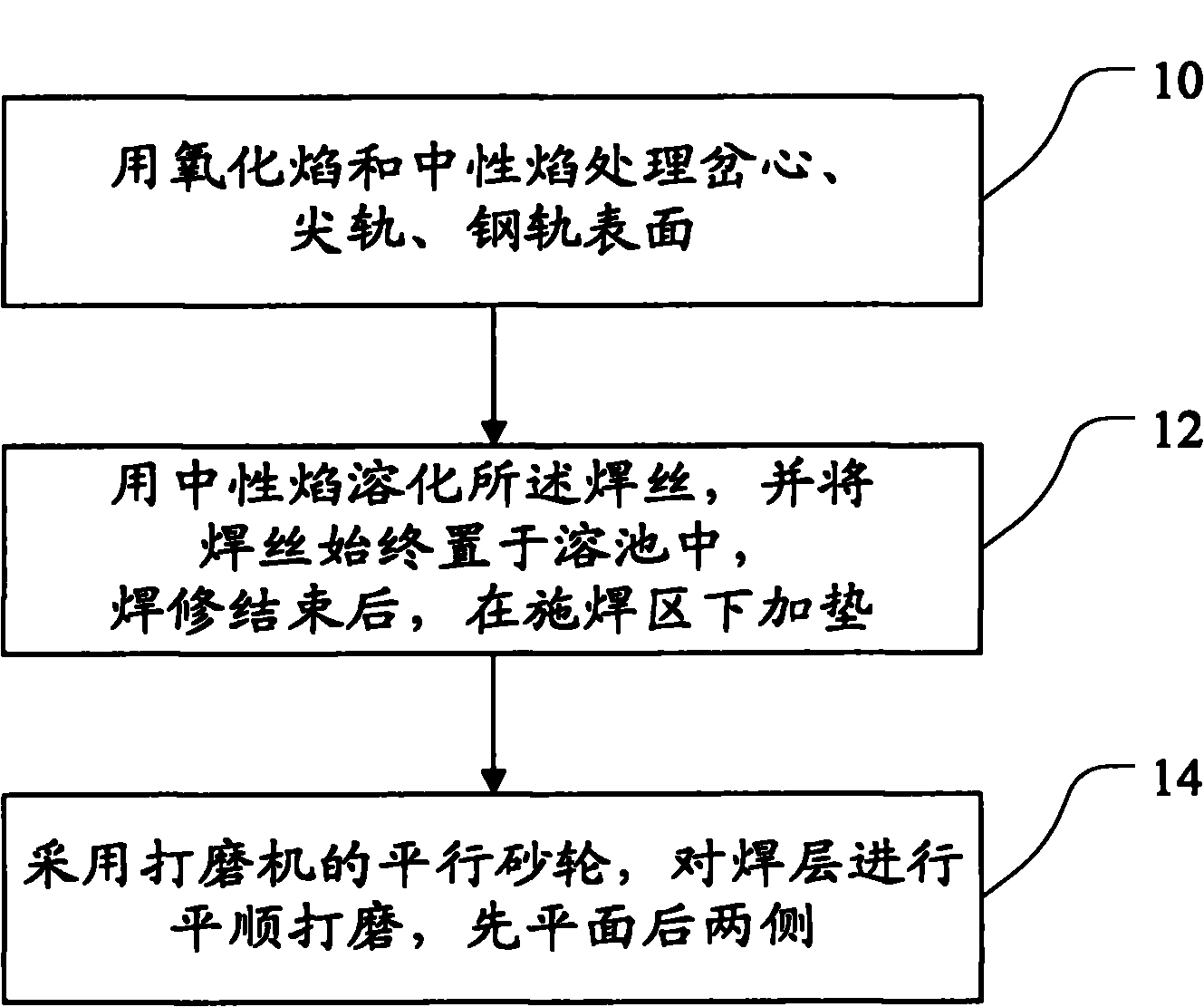

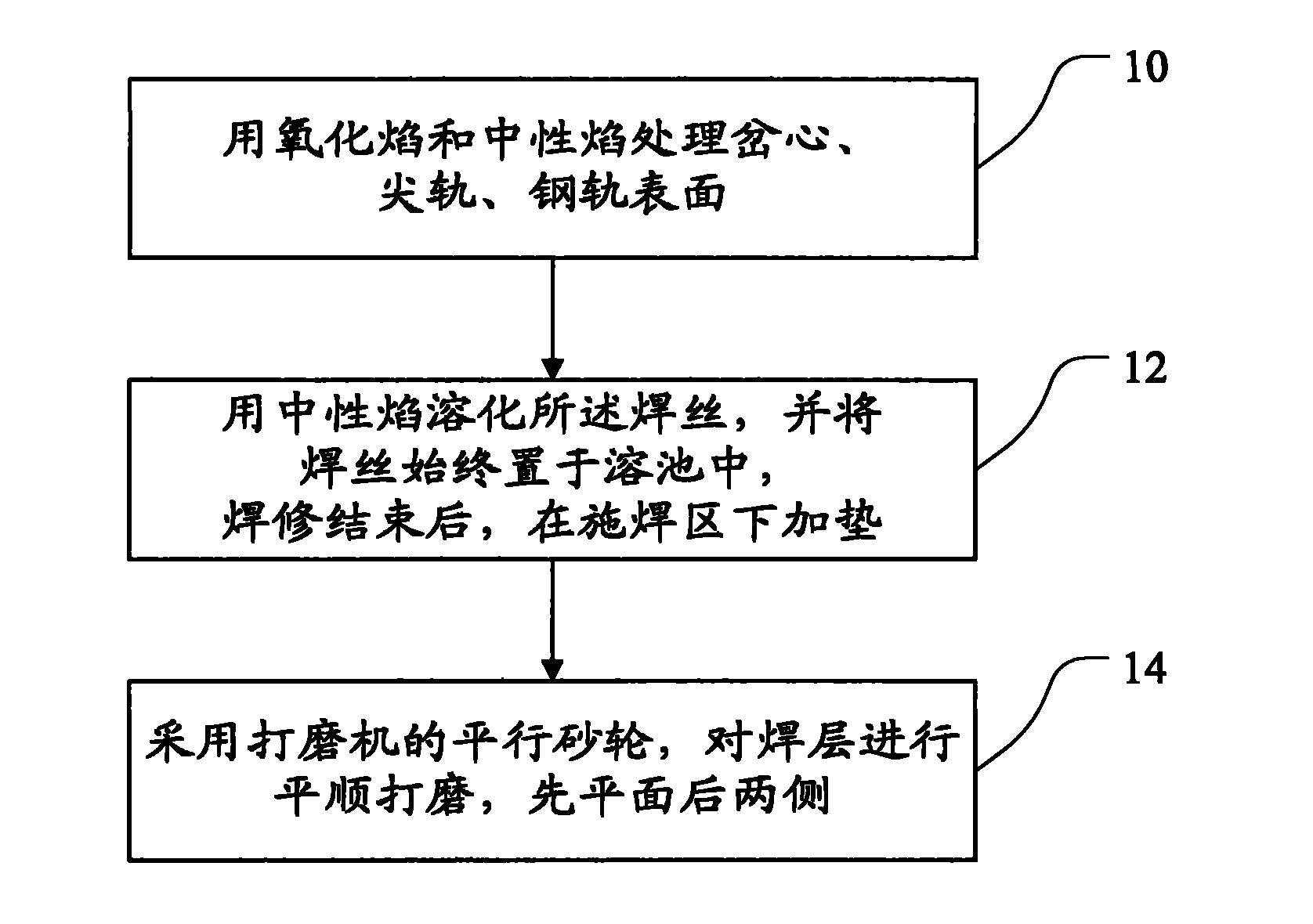

[0048] On the other hand, the present invention also discloses a method for using the welding wire of the present invention to carry out the gas welding and repairing operation of Bell's center and point rail, refer to figure 1 , including the follow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap