Bending molding process for wooden product solid wood

A technology for bending molding and wood products, which is applied in the direction of wood bending, manufacturing tools, wood processing appliances, etc., can solve the problems of chemical softener production environment adverse effects, high production cost, long process, etc., to achieve stable and reliable product quality, The effect of low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

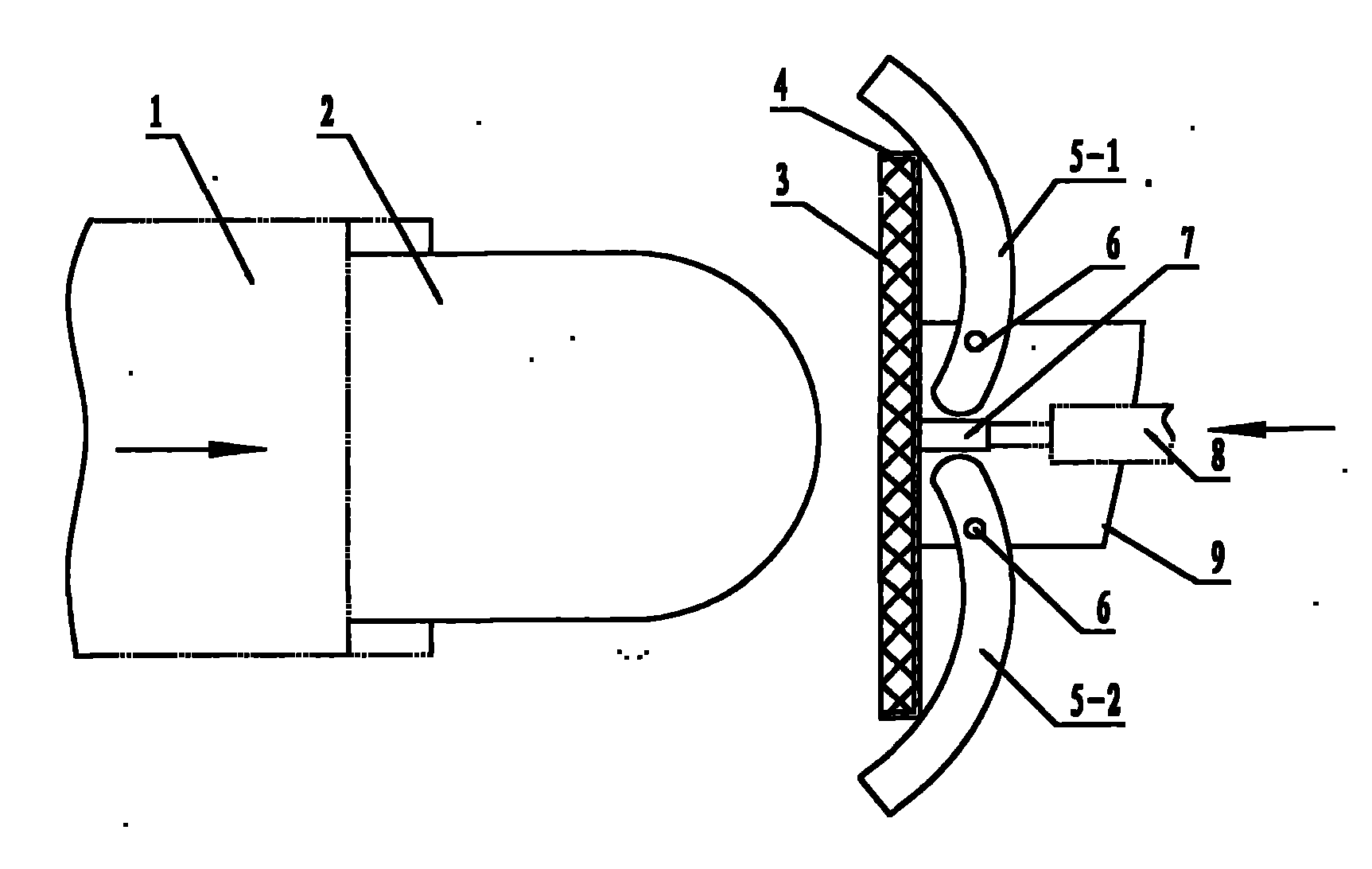

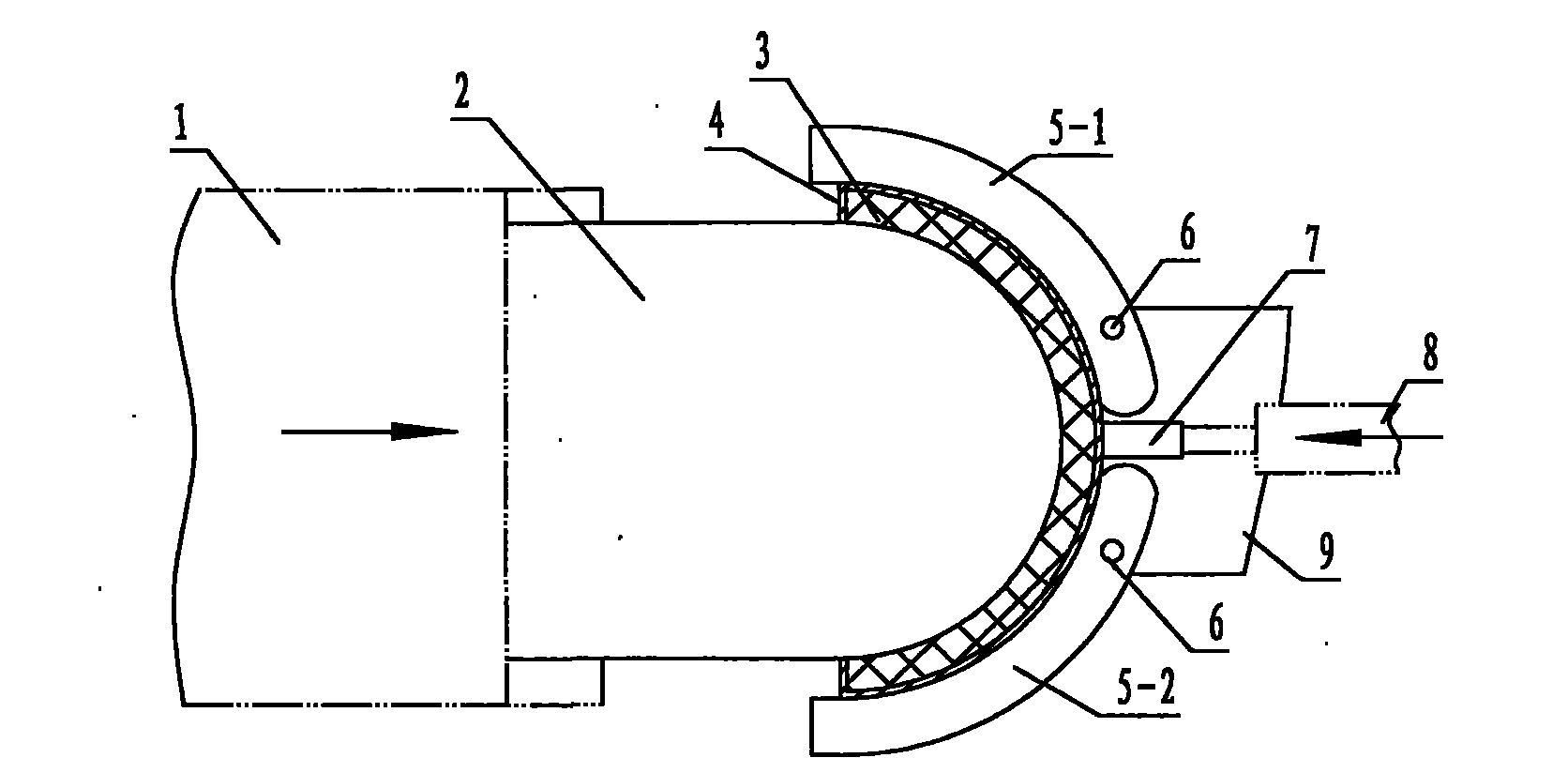

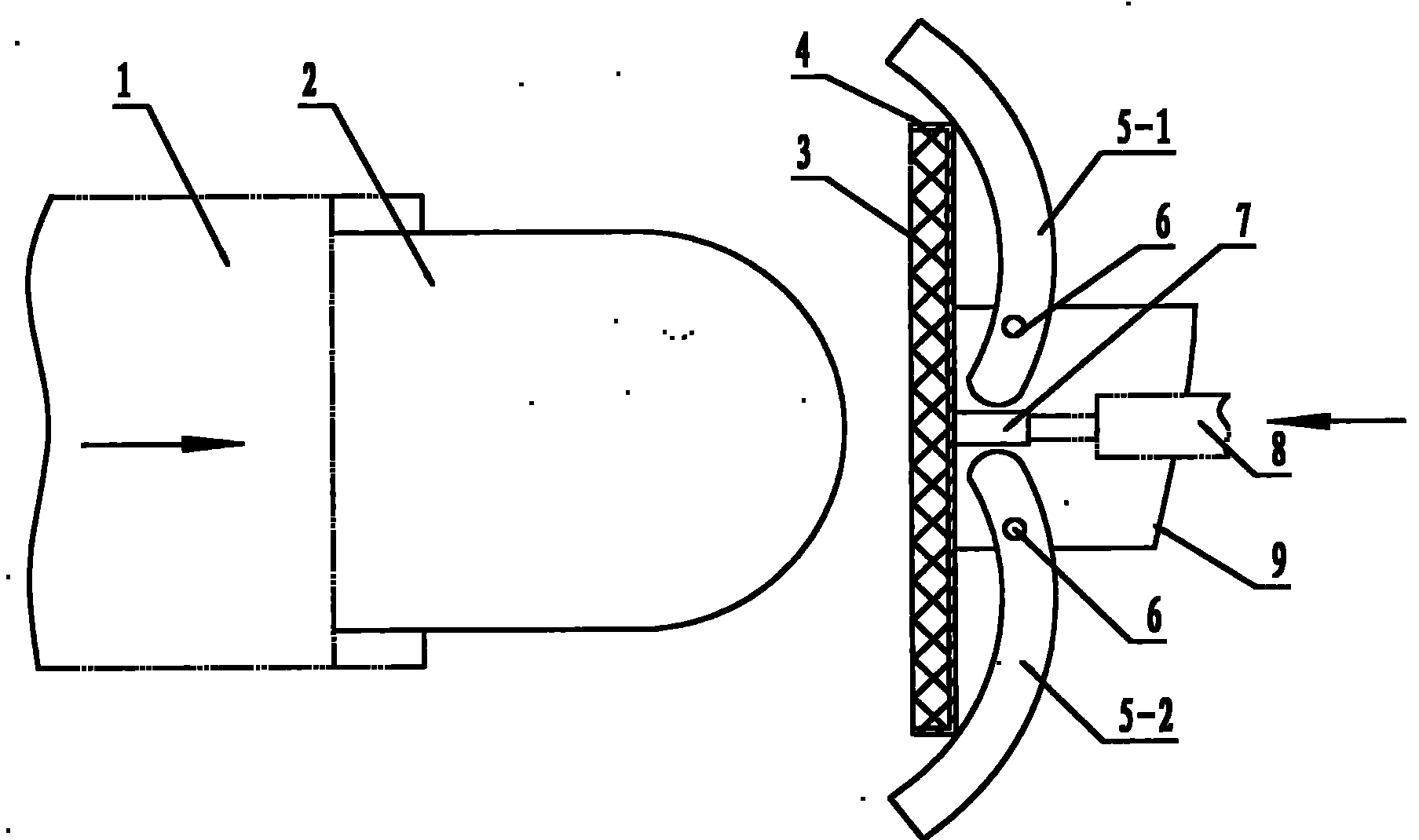

[0021] Embodiment 1: Oak piece 30 * 30mm square material, length 1000mm moisture content is 20~30%, blank is put into autoclave and feeds the steam of about 0.1Mpa to carry out steaming and softening for 1 hour; Solid wood blank after softening A protective steel belt is attached to one side and placed between the arc forming head of the inner mold and the arc forming surface of the outer mold. The inner mold moves to the side of the solid wood blank under the action of the pressure device and exerts force on it. On the other side of the billet, the back pressure is applied by the top block under the action of the back pressure device, and the two split modules naturally rotate with the hinge point as the center of the circle with the bending deformation of the solid wood billet, and gradually hug the solid wood billet until the solid wood billet is bent and formed; After the molded solid wood molding blank is demoulded, it is discharged on a special material rack together with...

Embodiment 2

[0022] Embodiment 2: Fraxinus mandshurica piece 30 * 35mm square stock, length 960mm moisture content is 20~25%, billet is put into steamer and boils and softens for 2 hours; The solid wood billet side after softening is attached protective steel band, Placed between the arc forming head of the inner mold and the arc forming surface of the outer mold, the inner mold moves to one side of the solid wood blank under the action of the pressure device and exerts force on it, and at the same time, the top block is placed on the other side of the solid wood blank. Back pressure is applied under the action of the back pressure device, and the two split modules rotate naturally with the hinge point as the center of the circle along with the bending and deformation of the solid wood blank, and the solid wood blank is gradually embraced until the solid wood blank is bent and formed; Frequency electromagnetic field energy, drying time about 30 minutes.

Embodiment 3

[0023] Embodiment 3: Beech piece 28 * 30mm square material, length 900mm moisture content is 16~20%, blank is put into steam box and is boiled and softened for 1.5 hours; The solid wood blank side after softening is attached protective steel belt, places Between the arc forming head of the inner mold and the arc forming surface of the outer mold, the inner mold moves to one side of the solid wood blank under the action of the pressure device and exerts force on it, and at the same time, the top block presses on the other side of the solid wood blank Under the action of the device, the back pressure is applied, and the two split modules naturally rotate with the bending and deformation of the solid wood blank with the hinge point as the center of the circle, and the solid wood blank is gradually embraced until the solid wood blank is bent and formed; Put it on a special rack and put it in a drying room to dry for one day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com