Treatment device of waste liquid/slag

A treatment device and waste liquid technology, which is applied in the direction of heating water/sewage treatment, etc., can solve the problems of waste alkali that cannot be recycled, waste, and endanger the environment, and achieve sustainable development, energy saving, and improvement of heat utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

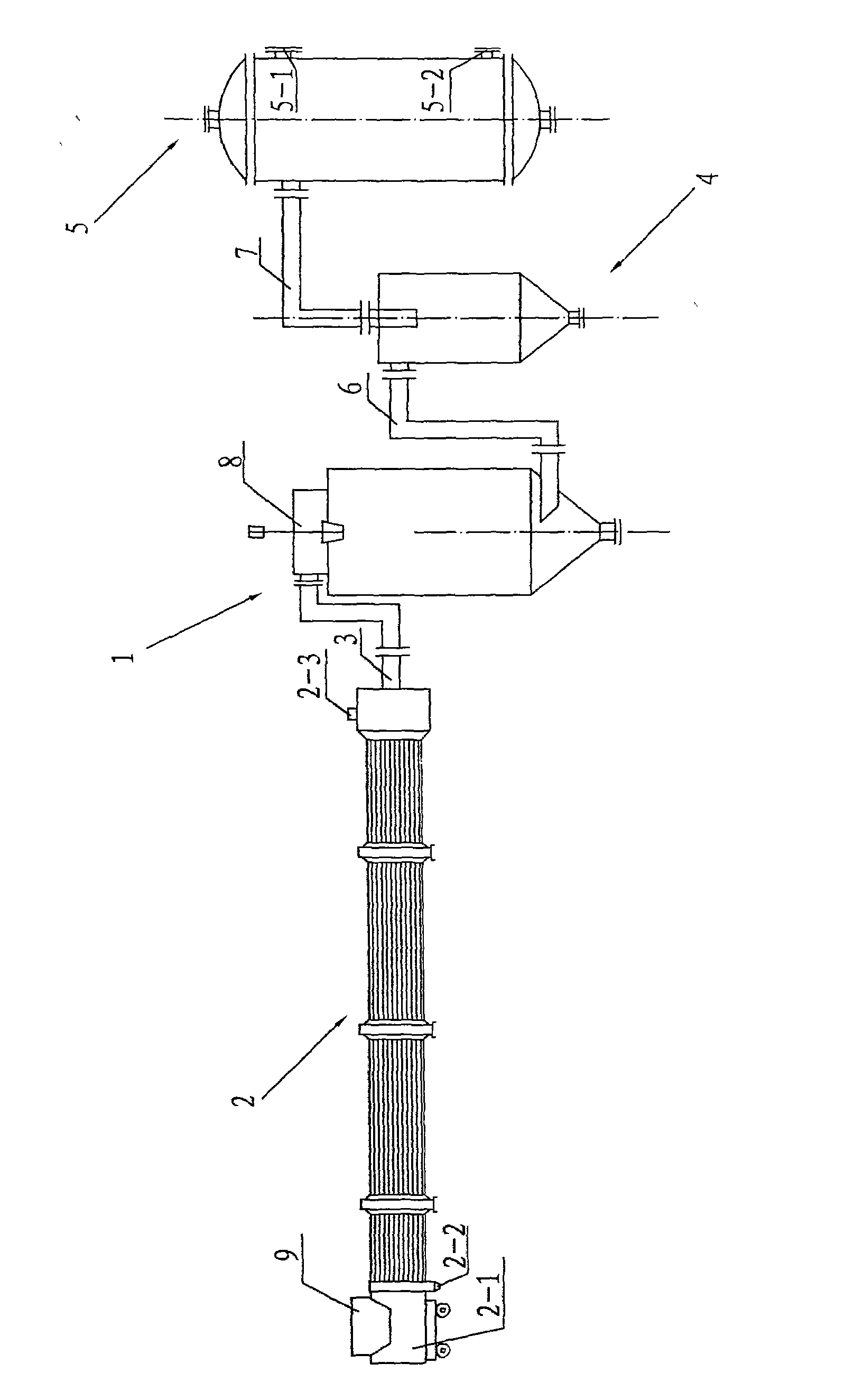

[0041] A treatment device for waste liquid / slag, which includes a spray absorption reactor 1 and a rotary kiln 2 connected by a pipeline A3; the device also includes a cyclone separator 4 and a heat exchanger 5, and the cyclone separator 4 and the spray The absorption reactor 1 is connected through a pipeline B6, and the heat exchanger 5 is connected with the cyclone separator 4 through a pipeline C7; a high-speed centrifugal sprayer 8 is arranged in the inlet of the spray absorption reactor 1; the rotary kiln 2 The kiln head 2-1 outside is provided with evaporator 9.

Embodiment 2

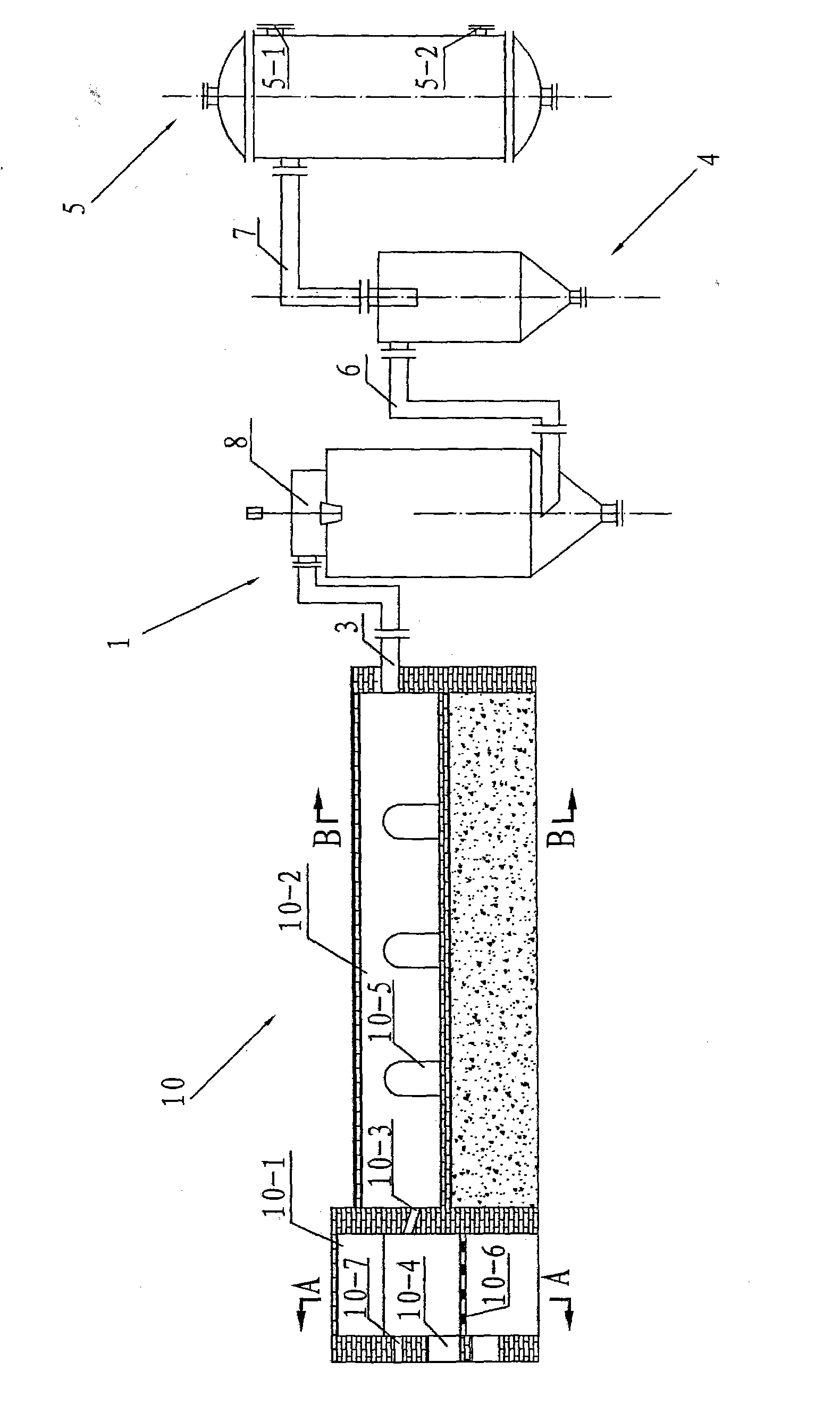

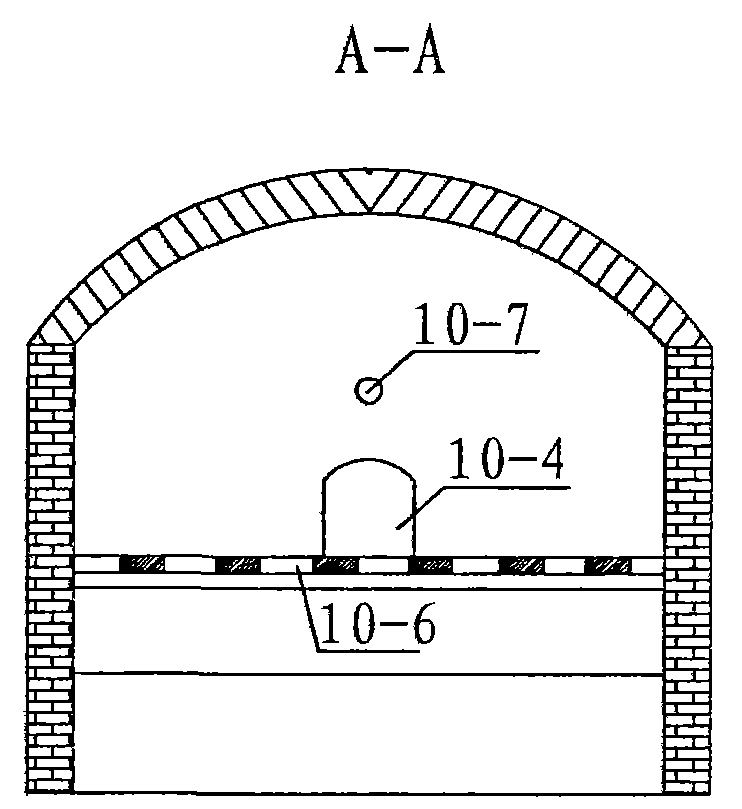

[0043]The treatment device of waste liquid / slag, this device comprises the spray absorption reactor 1 and the carbonization reaction furnace 10 that are connected by pipeline A3; This device also comprises cyclone separator 4 and heat exchanger 5, and described cyclone separator 4 and described The spray absorption reactor 1 is connected through a pipeline B6, and the heat exchanger 5 is connected with the cyclone separator 4 through a pipeline C7; a high-speed centrifugal sprayer 8 is arranged in the inlet of the spray absorption reactor 1; the carbonization reaction The furnace 10 includes a furnace head 10-1 and a material tank 10-2 connected by a flame port 10-3; a fuel inlet 10-4 is arranged on the furnace head 10-1; The heat path is provided with a material door 10-5; the end of the flame port 10-3 connected to the burner 10-1 is slightly higher than the end connected to the material pool 10-2; the end of the material pool 10-2 The height of the indoor plane is slightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com