Air sucking and pressing type high-efficiency energy-saving instant quick low-temperature sludge drying, disinfecting and fresh keeping method and device

A high-efficiency, energy-saving, treatment device technology, applied in dewatering/drying/concentrated sludge treatment, heating, etc., can solve the problem of difficult to estimate effect, and achieve the effects of low heat loss, less land occupation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

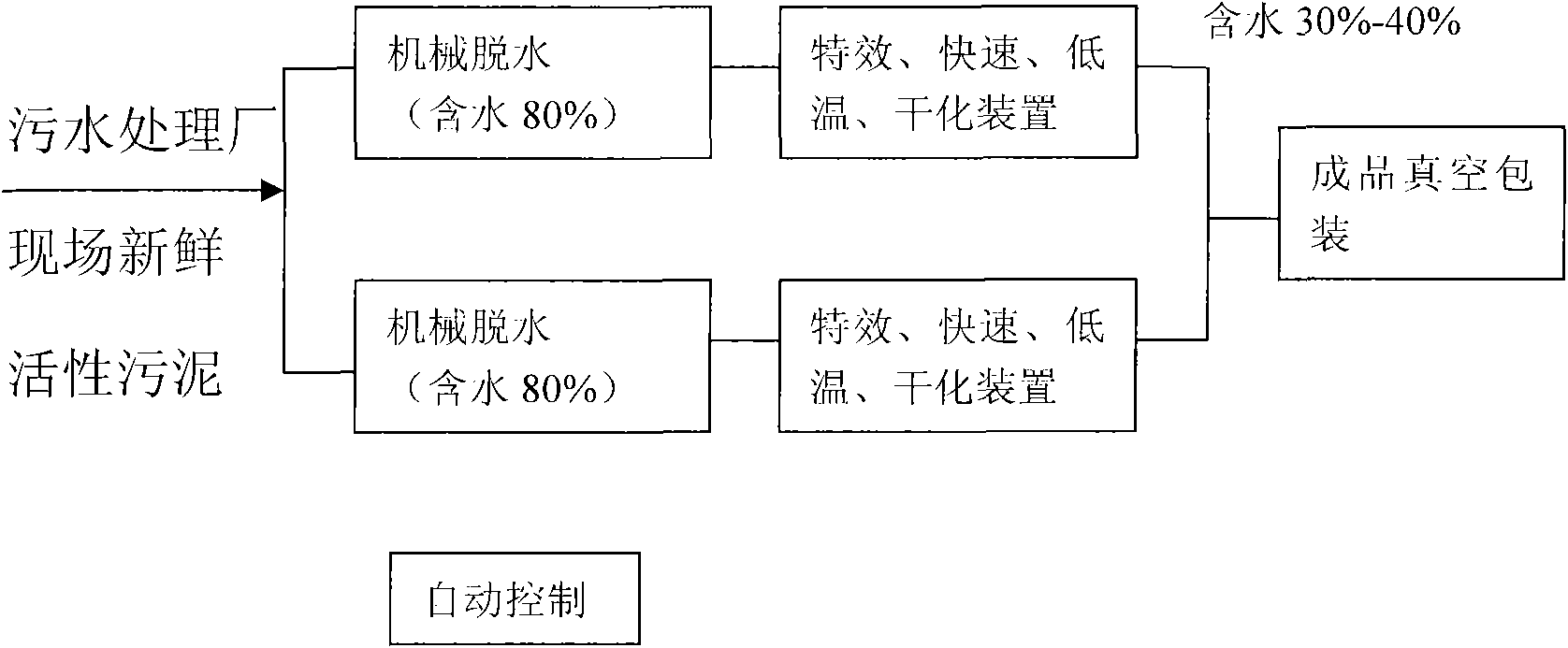

[0055] Embodiment 1: A kind of air-pumping type high-efficiency energy-saving sludge instant rapid low-temperature drying disinfection preservation treatment method, its process steps are:

[0056] (1) Get the fresh activated sludge that sewage treatment plant produces, carry out conventional mechanical dehydration, obtain the preliminary dewatered sludge that weight percentage water content is 78%-82%;

[0057] (2) Put the preliminary dewatered sludge into the closed inner cylinder of the drying furnace, then start the pulverizing agitator in the inner cylinder and heat the preliminary dewatered sludge in the inner cylinder to not lower than 40°C; the closed inner cylinder of the drying furnace Located in the outer cylinder, and there is a heat exchange chamber between the inner wall of the outer cylinder and the outer wall of the closed inner cylinder;

[0058] (3) Start the pumping air machine, pump out the water vapor in the closed inner cylinder and press the extracted wa...

Embodiment 2

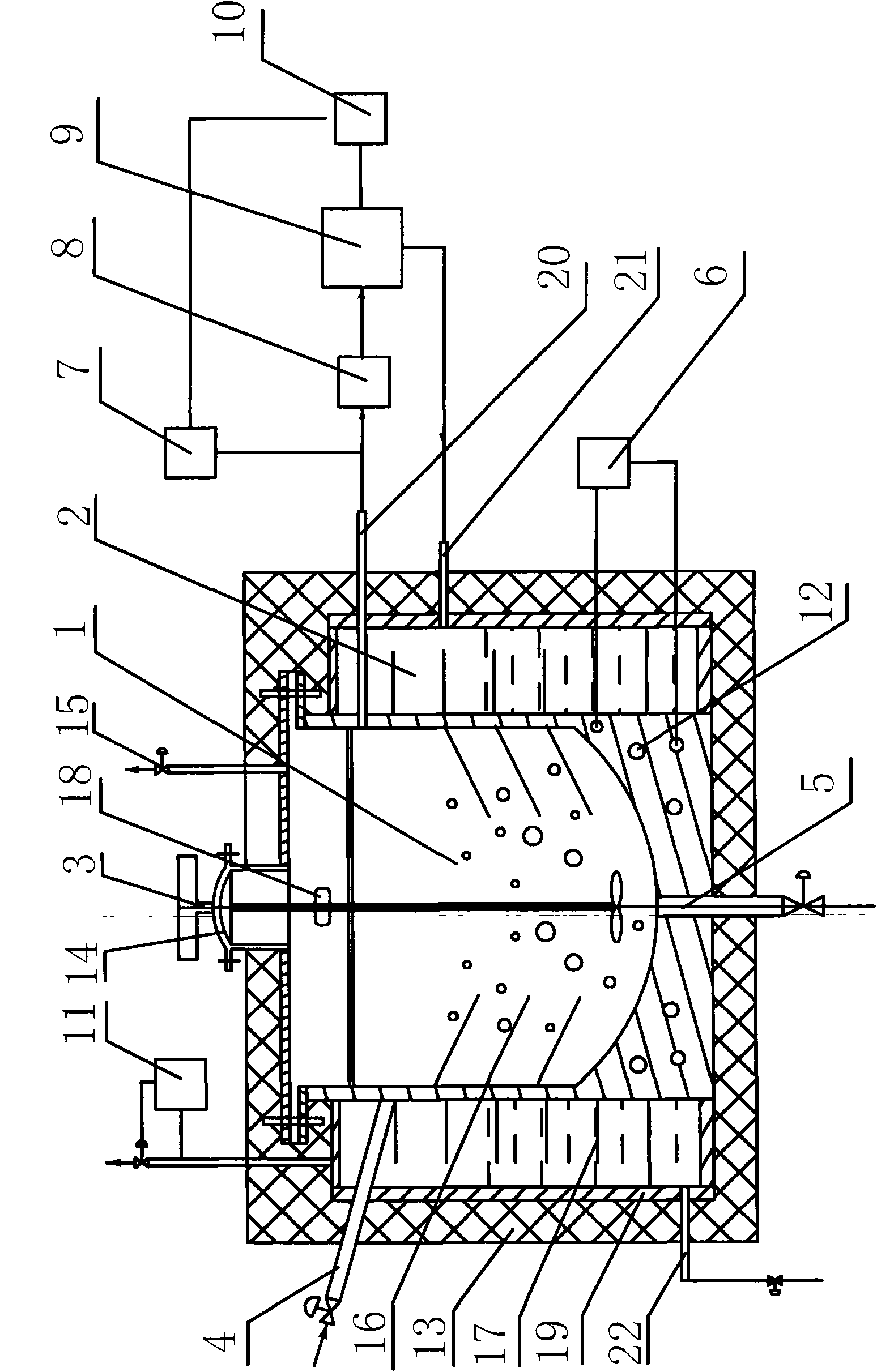

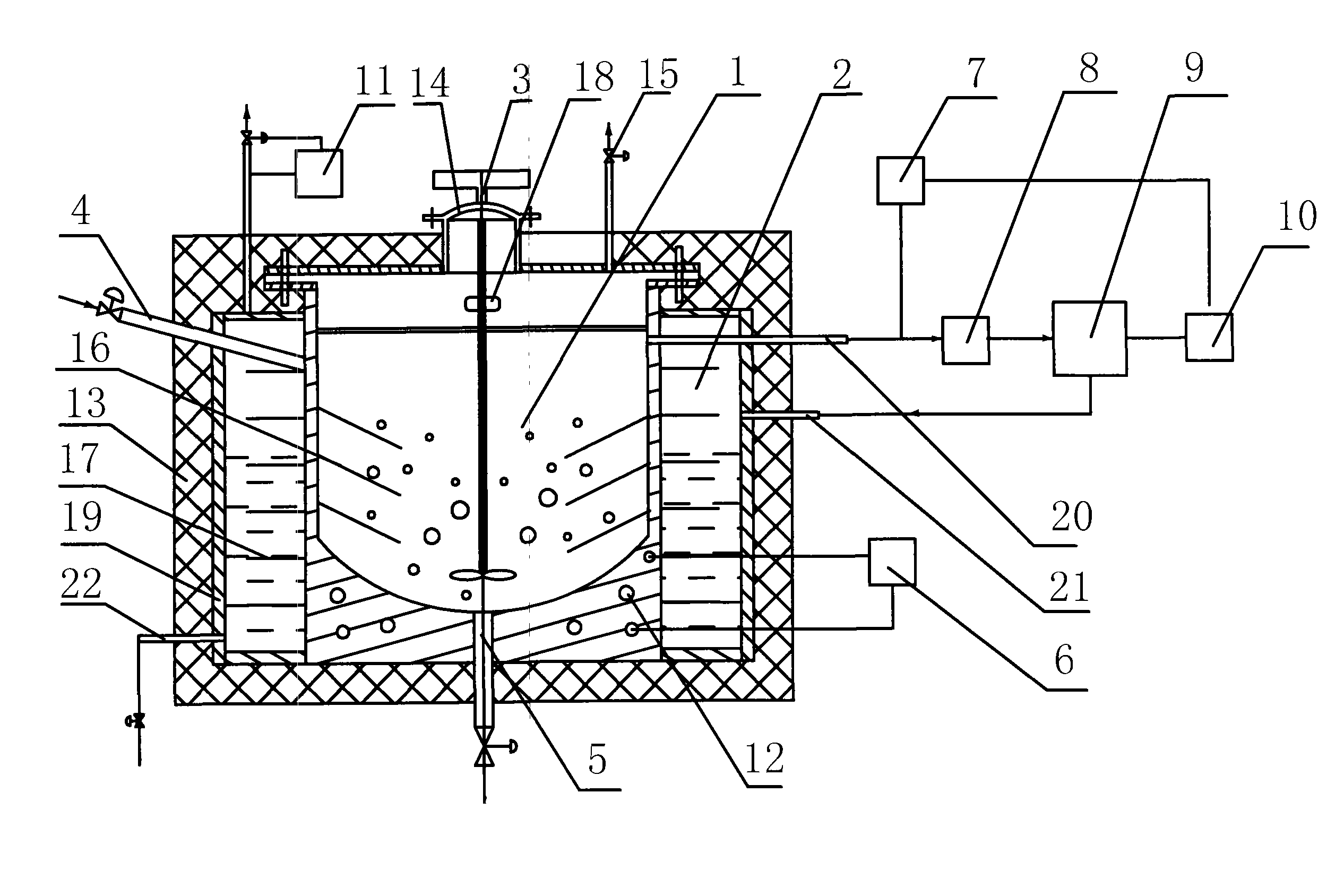

[0065] Embodiment 2: a kind of pumping air type high-efficiency energy-saving sludge instant rapid low-temperature drying disinfection fresh-keeping treatment device, its structure is (such as figure 2 shown), it has an outer cylinder 19 with an insulating layer 13 on its periphery, a closed inner cylinder 1 is located in the outer cylinder 19, and there is a heat exchange chamber 2 between the outer wall of the closed inner cylinder 1 and the inner wall of the outer cylinder 19; the closed inner cylinder 1 The bottom is equipped with an electric heating element 12 connected with a temperature measuring heating controller 6 and a dry mud discharge pipe 5 with a valve, and the closed inner cylinder 1 with a vent valve 15 on the top is provided with a crushing type agitator 3. The upper part of the inner cylinder 1 is also provided with a feed pipe 4 with a feed valve; the air inlet of the air pump 9 driven by the frequency conversion motor 10 communicates with the air suction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com