Anti-crack fiber for water reducing type concrete and mortar

A technology of anti-cracking fiber and concrete, which is applied in the fields of anti-cracking fiber for mortar and water-reducing concrete, and can solve the problems of adding anti-cracking and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

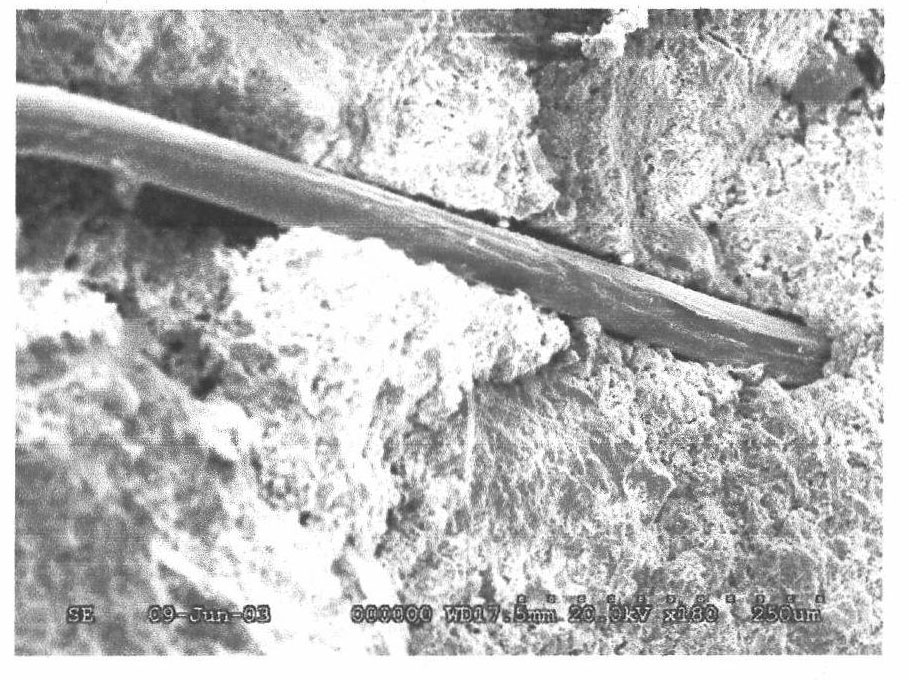

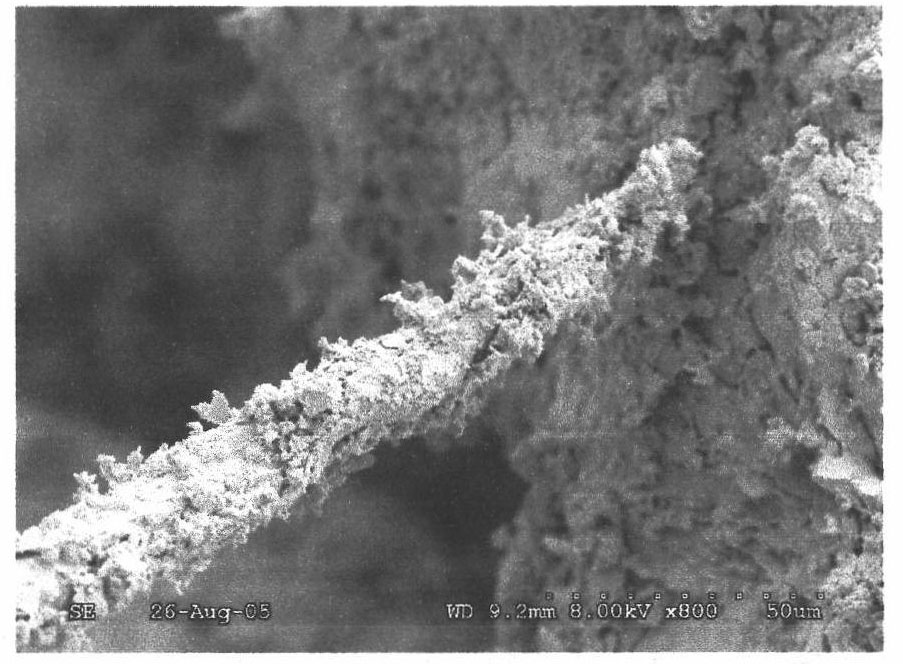

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments.

[0026] Anti-cracking fibers for water-reducing concrete and mortar are selected from horse chestnut wood, and the cellulose fibers with high strength and high elastic modulus are extracted through biological fiber extraction technology, and the surface of the extracted cellulose fibers is coated with a chemical alkali-resistant coating; Adding a water reducer to the cellulose fibers coated with a chemical alkali-resistant coating to prepare water-reducing concrete and anti-cracking fibers for mortar, wherein the water-reducing agent is polycarboxylate water-reducer or naphthalene sulfonate Formaldehyde condensation product water reducing agent, the weight ratio of the cellulose fiber to the water reducing agent is: cellulose fiber: 15%-30%; water reducing agent: 70%-85%; wherein the water reducing rate of the water reducing agent is not less than 20%.

[0027] Cellulose fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com