A method for enriching n-glycopeptides or n-sugar chains

A sugar chain and enrichment technology, applied in the field of enriching N-glycopeptides or N-glycosides, can solve the problems of complex operation steps, time-consuming and high technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

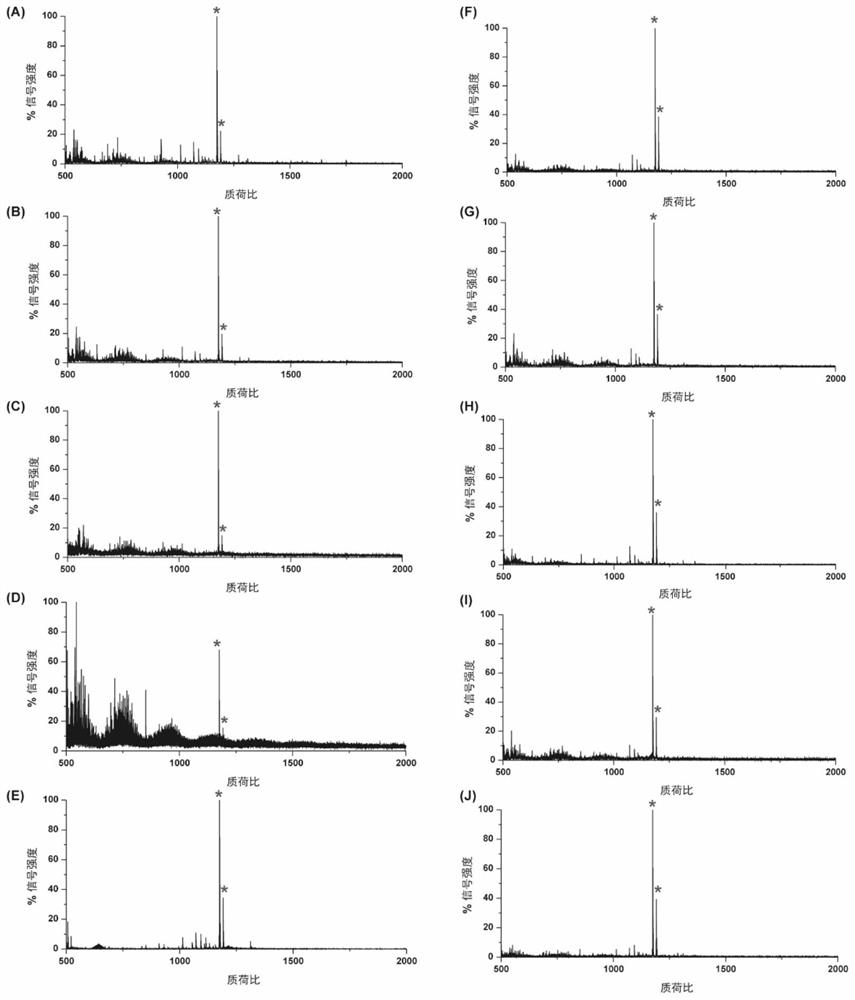

[0044] The enrichment of embodiment 1N-glycopeptide

[0045] Bacterial cellulose pieces were cut into 1 cm × 1 cm pieces to obtain BC pieces, which were washed 3 times with distilled water, and then, BC pieces were freeze-dried and stored at 4 °C for further use.

[0046] Proteins were diluted in 50 mM ammonium bicarbonate (ABC) buffer at a concentration of 2 μg / μL and denatured in a 100° C. water bath for 5 min. Proteins were then reduced with 10 mM DTT for 1 h at 37°C, followed by alkylation with 25 mM IAA for 0.5 h at 37°C. Then trypsin was added to the solution at an enzyme:protein ratio of 1:50 (w / w), incubated overnight at 37°C, and then boiled at 100°C for 5min to terminate the enzymatic hydrolysis reaction. Digested peptides were dried by vacuum centrifugation and stored at -20°C for later use.

[0047] To obtain a mixture of sugar chains from the peptide, the lyophilized peptide from the last step was dissolved in 50 mM ABC, and the peptide N- Glycosidase F release...

Embodiment 2

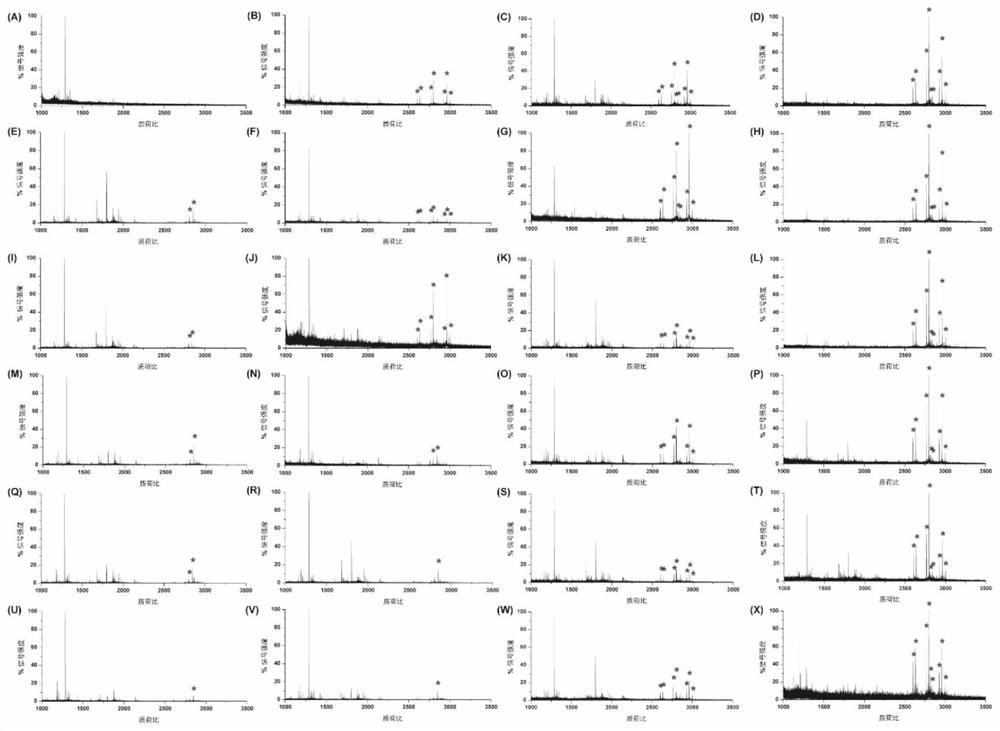

[0049] Example 2 Enrichment of N-sugar chains

[0050] Bacterial cellulose pieces were cut into 1 cm × 1 cm pieces to obtain BC pieces, which were washed 3 times with distilled water, and then, BC pieces were freeze-dried and stored at 4 °C for further use.

[0051] Proteins were diluted in 50 mM ammonium bicarbonate (ABC) buffer at a concentration of 2 μg / μL and denatured in a 100° C. water bath for 5 min. Proteins were then reduced with 10 mM DTT for 1 h at 37°C, followed by alkylation with 25 mM IAA for 0.5 h at 37°C. Then trypsin was added to the solution at an enzyme:protein ratio of 1:50 (w / w), incubated overnight at 37°C, and then boiled at 100°C for 5min to terminate the enzymatic hydrolysis reaction. Digested peptides were dried by vacuum centrifugation and stored at -20°C for later use.

[0052] To obtain the glycan mixture from the peptide, the lyophilized peptide in the last step was dissolved in 50 mM ABC, and the glycan peptide was added at an enzyme:protein ra...

Embodiment 3

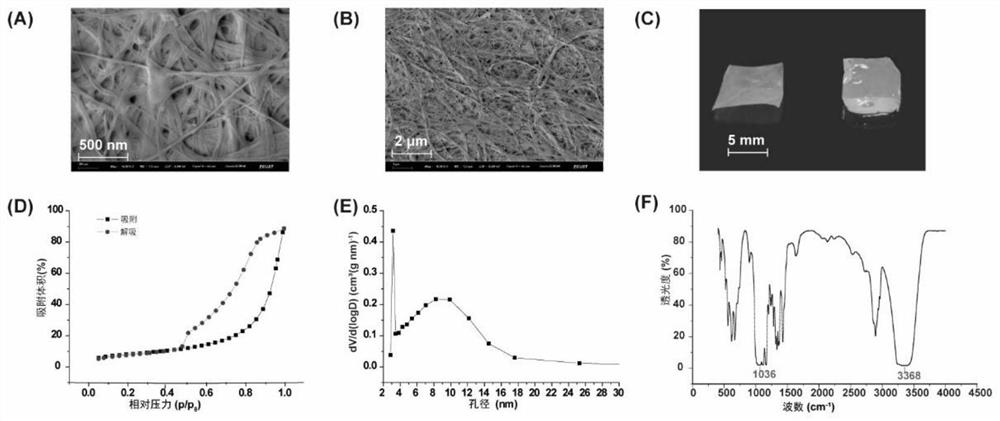

[0054] Example 3 Characterization of bacterial cellulose

[0055] Bacterial cellulose is composed of sugar chains with β-1,4-glycosidic bonds and has an interconnected 3D porous network structure. The morphology of bacterial cellulose was observed by SEM. Such as image 3 As shown in A and 3B, bacterial cellulose has a nanoscale fiber structure. The interconnected 3D porous network structure provides high specific surface area, strong flexibility and high tensile strength. Bacterial cellulose has a remarkable water absorption capacity. Bacterial cellulose forms solid sheets after drying, while the solution swells like a gel after absorption ( image 3 C). Significant water capacity was evaluated by mass change before and after water absorption. Bacterial cellulose can absorb 80 times its own weight in water.

[0056] The nitrogen adsorption-desorption isotherm further proved the porous structure of bacterial cellulose ( image 3 D). The hysteresis loop representing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com