Method for producing maleic anhydride by using o-xylene as dehydrating agent

A technology of o-xylene and dehydrating agent, applied in the field of maleic anhydride products, can solve the problems of slow dehydration speed and low purity of maleic anhydride, achieve fast dehydration speed and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

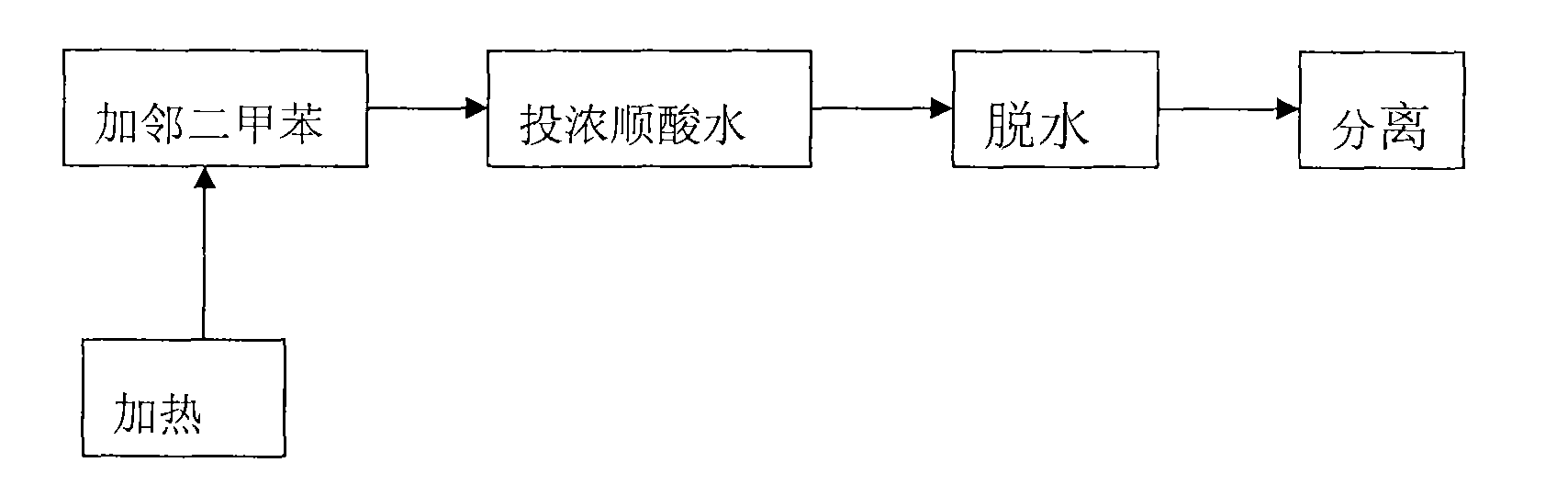

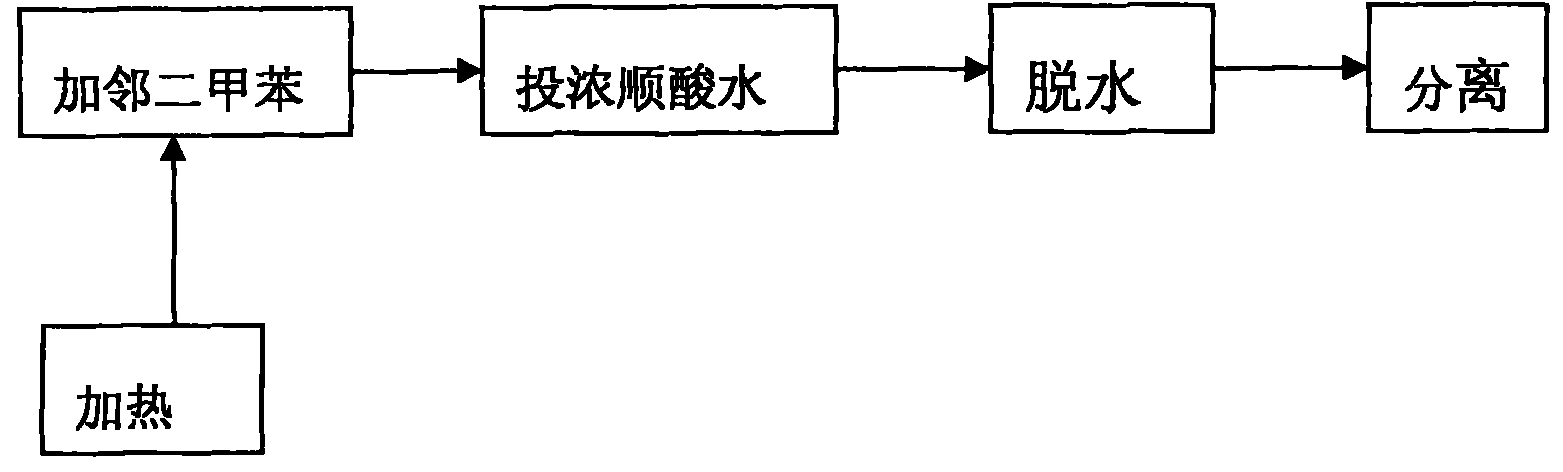

[0015] Depend on figure 1 Know, the method that uses ortho-xylene of the present invention produces maleic anhydride as dehydrating agent, comprises the following steps: 1, adds ortho-xylene: 2, throws concentrated maleic acid water: 3, dehydration: 4, separates.

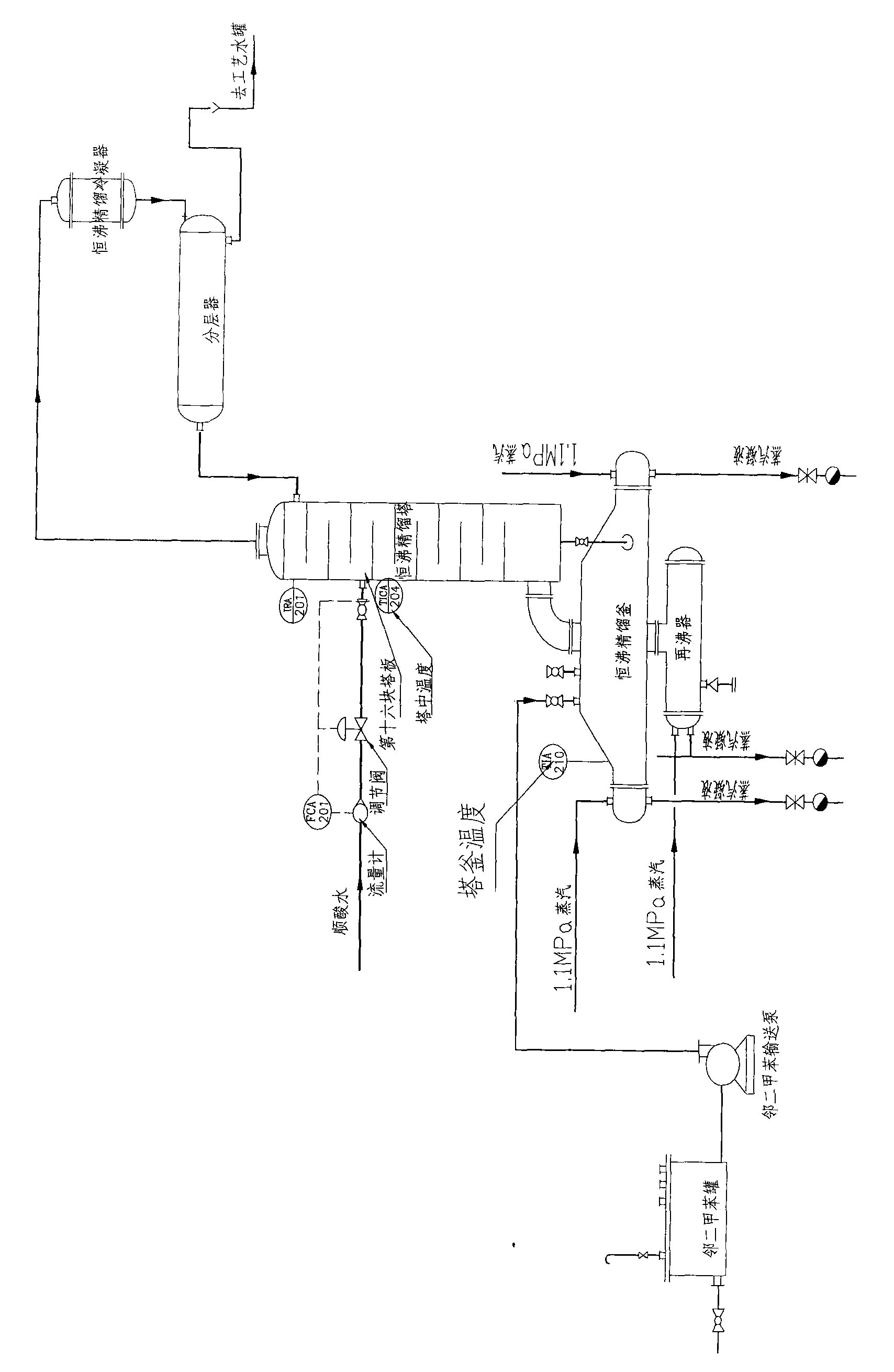

[0016] Depend on figure 2 It is the process flow diagram of the production of maleic anhydride of the present invention. Its technological process is:

[0017] 1. Add o-xylene: from the o-xylene storage tank through the o-xylene delivery pump, put 30000±5Kg of o-xylene with a purity of more than 99.9% as a dehydrating agent into the azeotropic rectification kettle equipped with a heating coil, and use a The heating coil reboiler is used for heating. The heat source of the heating coil is 1.1Mpa steam, so that the o-xylene is fully refluxed in the tower, and the temperature of the azeotropic distillation kettle reaches 145±0.5°C;

[0018] 2. Thick acid water injection: open the valve of the azeotropic rectificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com