Free monitoring point increase and decrease direct digital controller

A technology of digital controllers and monitoring points, which is applied in the direction of program control and electrical program control in sequence/logic controllers, can solve problems such as error-prone, high cost, and long processing cycle, and avoid redundancy of monitoring points , avoid cost and waste, avoid the effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure of the direct digital controller for freely increasing or decreasing monitoring points of the present invention will be described with reference to the accompanying drawings and embodiments.

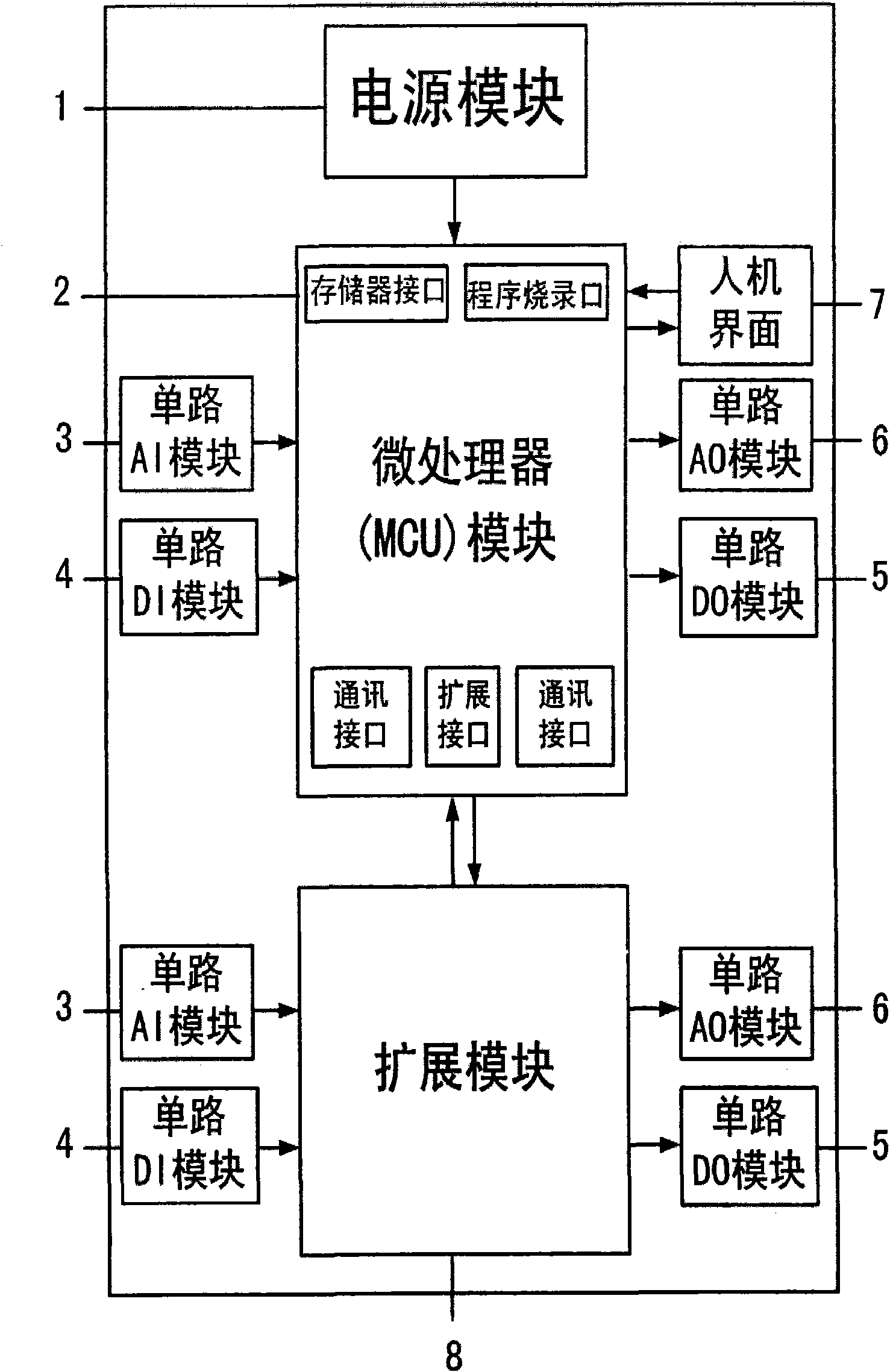

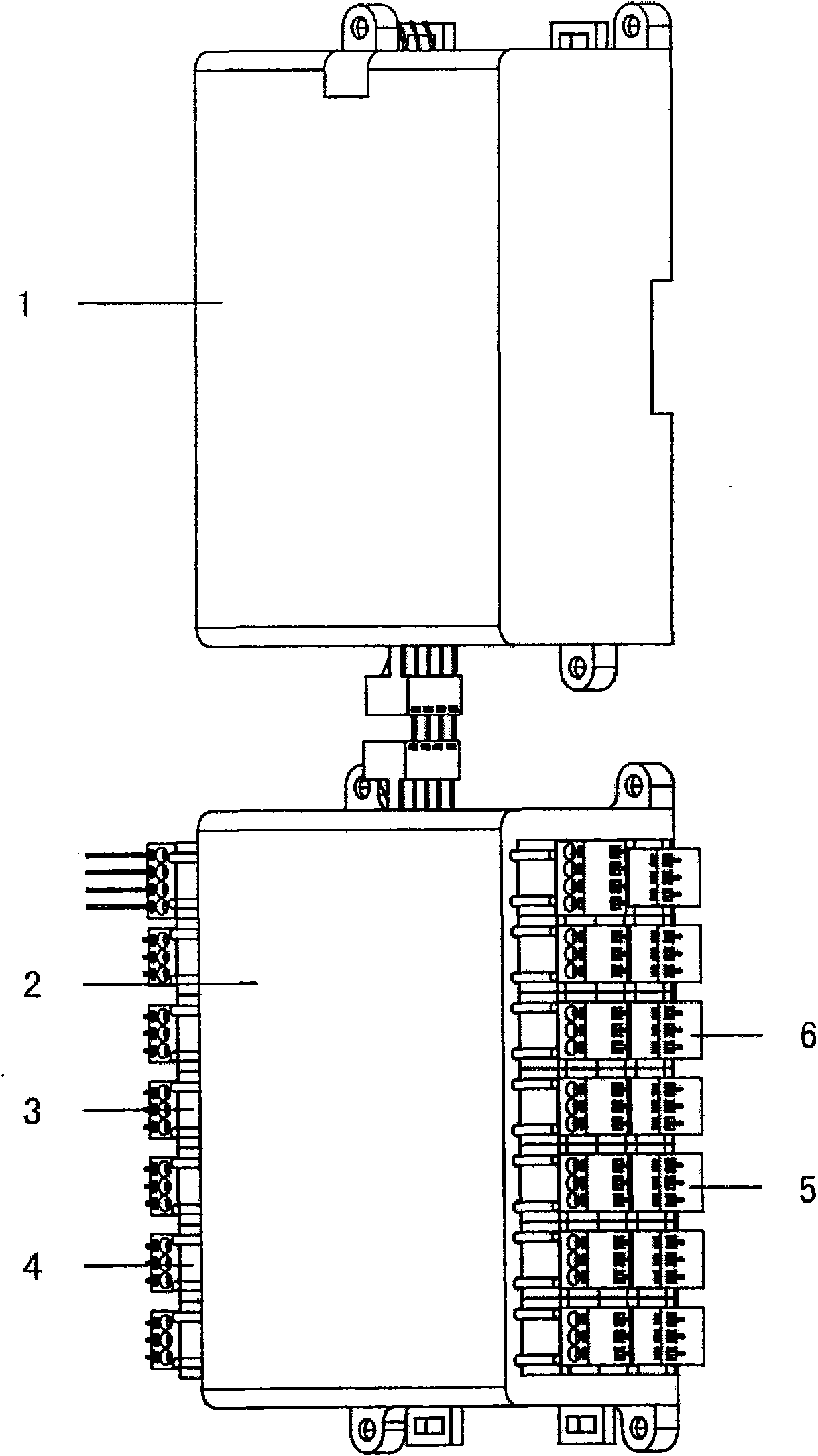

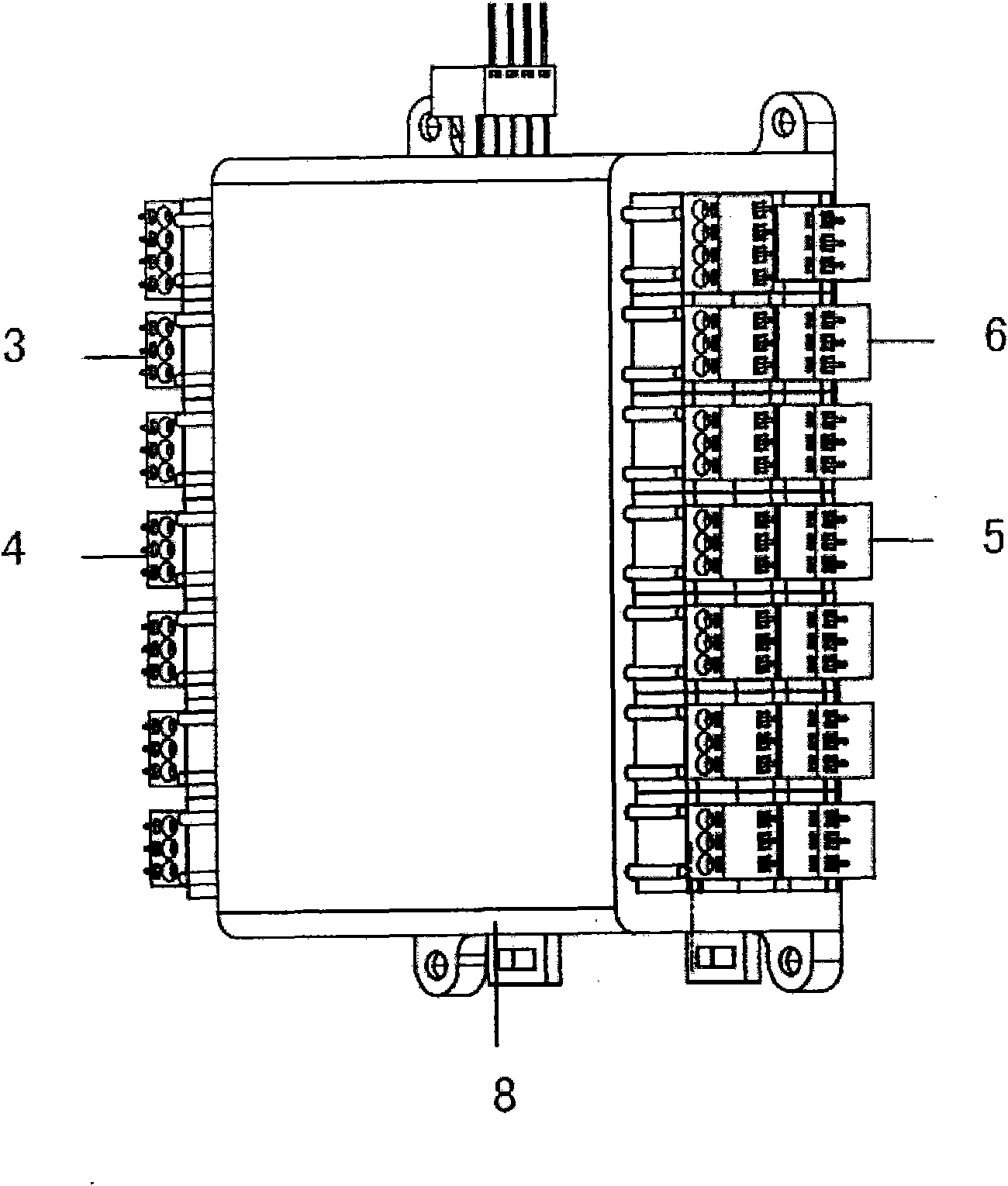

[0016] Such as figure 1 As shown, the structure of the direct digital controller with free increase and decrease of monitoring points of the present invention is that the controller includes a power supply module with unequal power 1, a microprocessor module MCU with different processing speeds, and an AI module with the same single analog input 3. The same single-channel digital input DI module 4, the same single-channel analog output AO module 6, the same single-channel digital output DO module 5, the man-machine interface 7 and the expansion module 8; the microprocessor module MCU2 and Power supply module 1 is plugged in with connection point terminals, microprocessor module MCU2 and single analog input AI module 3, single digital input DI module 4, single analog outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com