Separated drive spindle system of ultraprecision machining tool

An ultra-precision machining and driving technology, applied in the direction of metal processing equipment, etc., can solve the problems of poor power transmission effect and influence on the rotation accuracy of the spindle, and achieve the effect of high rotation, small heating deformation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

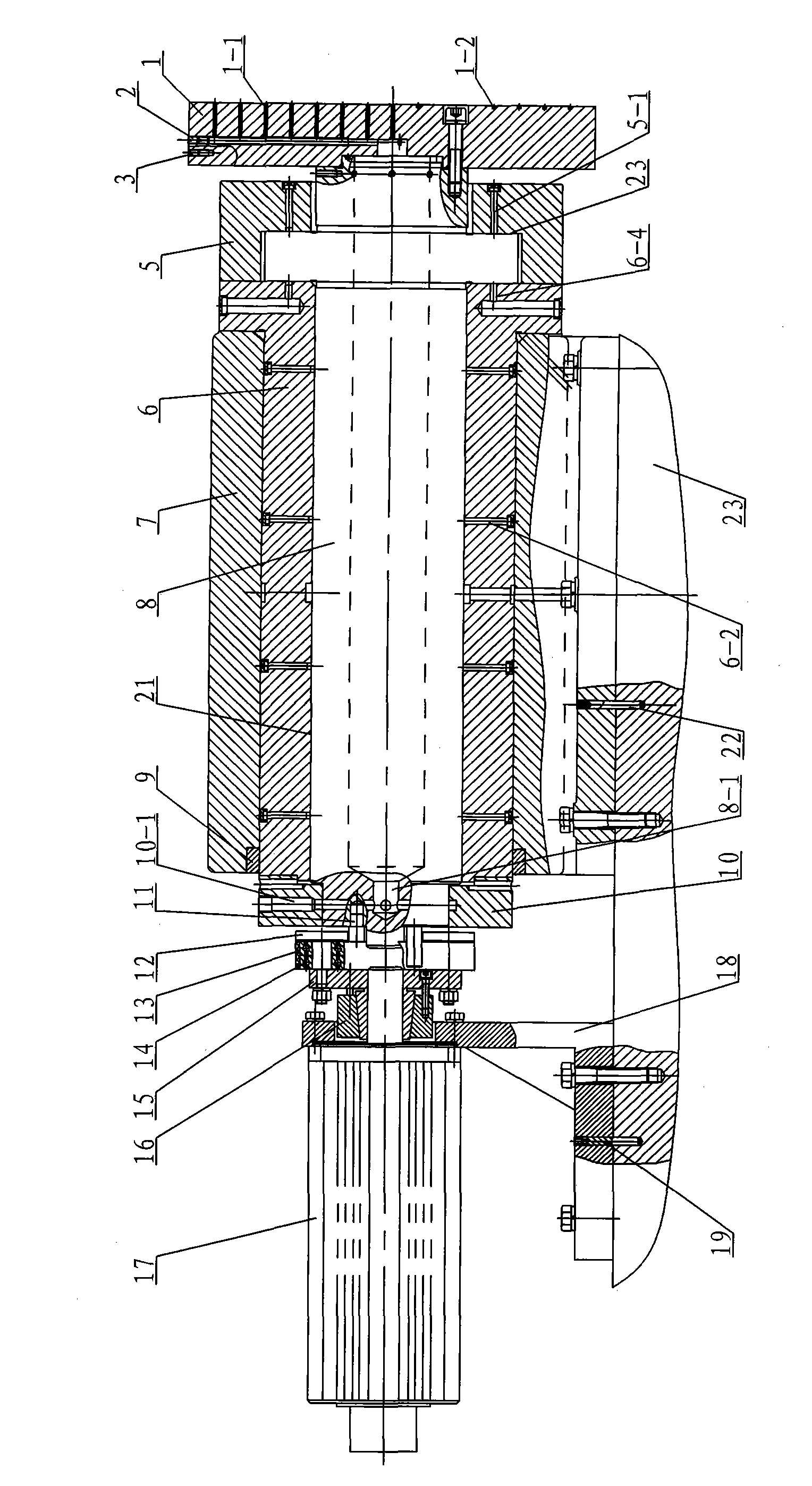

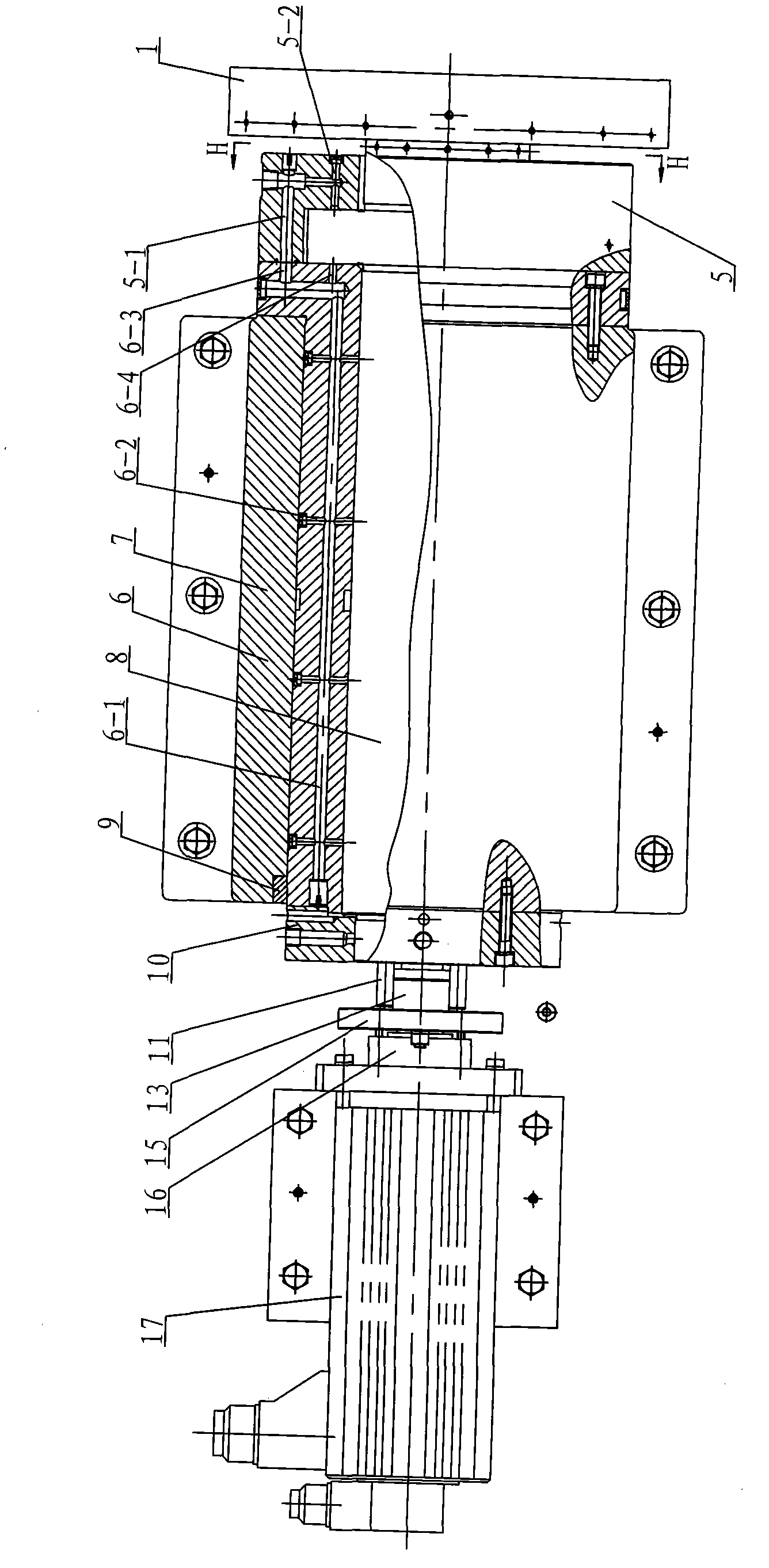

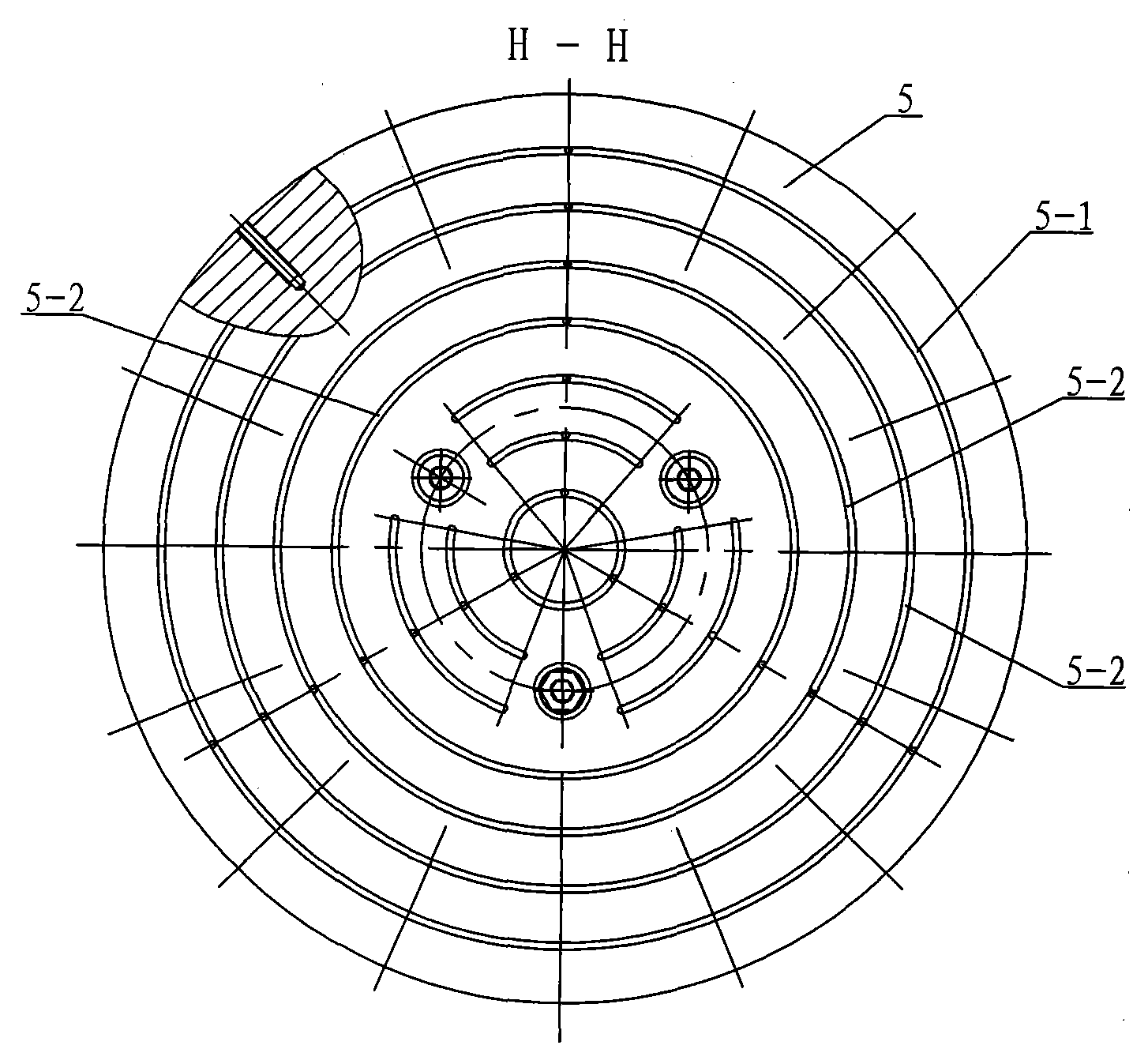

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment includes an AC servo motor 17, a motor base 18, a first positioning pin 19, a second positioning pin 22, a sliding plate 23, a static pressure gas spindle assembly, a flexible drive assembly and two levers 11, The static pressure gas spindle assembly is composed of air suction cup 1, thrust bearing 5, radial bearing 6, spindle box 7, spindle 8, support ring 9 and gas distribution ring 10, the spindle 8 is installed in the inner hole of the radial bearing 6, There is a radial air film gap 21 between the inner diameter of the radial bearing 6 and the outer diameter of the main shaft 8, the radial bearing 6 is fixed in the main shaft box 7, the main shaft box 7 is connected with the sliding plate 23, and the second positioning pin 22 for positioning, the thrust bearing 5 is set on the output end of the main shaft 8, the thrust bearing 5 and the shaft shoulder end surfac...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. The difference between this embodiment and the first embodiment is that it also adds a support ring 9, which is arranged at the connection between the input end of the spindle box 7 and the radial bearing 6. This design is easy to install. Other components and connections are the same as those in the first embodiment.

[0009] Working principle: After the AC servo motor 17 is energized, the AC servo motor 17 starts to rotate, driving the flexible drive assembly to rotate, and the flat belt 13 rotates to drive the lever 11 to generate a rotational torque to drive the spindle 8 to rotate for cutting. The high-pressure air enters through the axial inlet hole 6-1, and after throttling through the radial throttle hole 6-2, a radial gas static pressure film is formed at the radial gas film gap 21, and the radial gas static pressure film supports The main shaft 8 and its radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com