Manufacturing method of valve rod of high temperature and high pressure cut-off valve

A high temperature and high pressure, manufacturing method technology, applied in the field of valve stem manufacturing, can solve the problems of turning tool head loss, high cost, inability to achieve, etc., and achieve the effects of easy mechanical operation, high safety pressure, and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: see figure 1 As shown, a method for manufacturing a valve stem of a high-temperature and high-pressure globe valve includes the following steps:

[0035] (1) The diameter of the valve stem of the high temperature and high pressure globe valve is processed to the required thread pitch diameter by turning and grinding in sequence;

[0036](2) Carry out cold extrusion, plastic forming, and rolling calibration to the valve stem obtained in step (1) by means of rolling to form the required external thread; the rolling means adopts extrusion wheel, forming wheel and correction wheel 3 a rolling wheel.

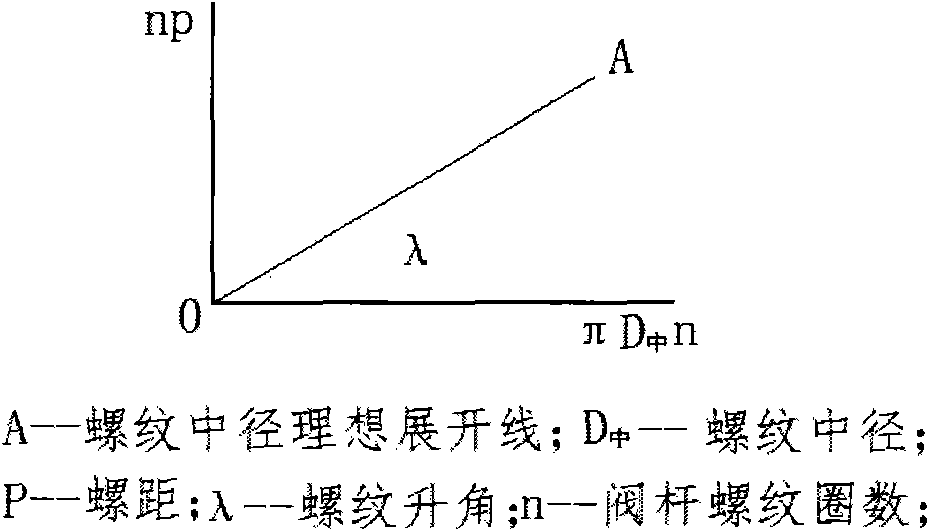

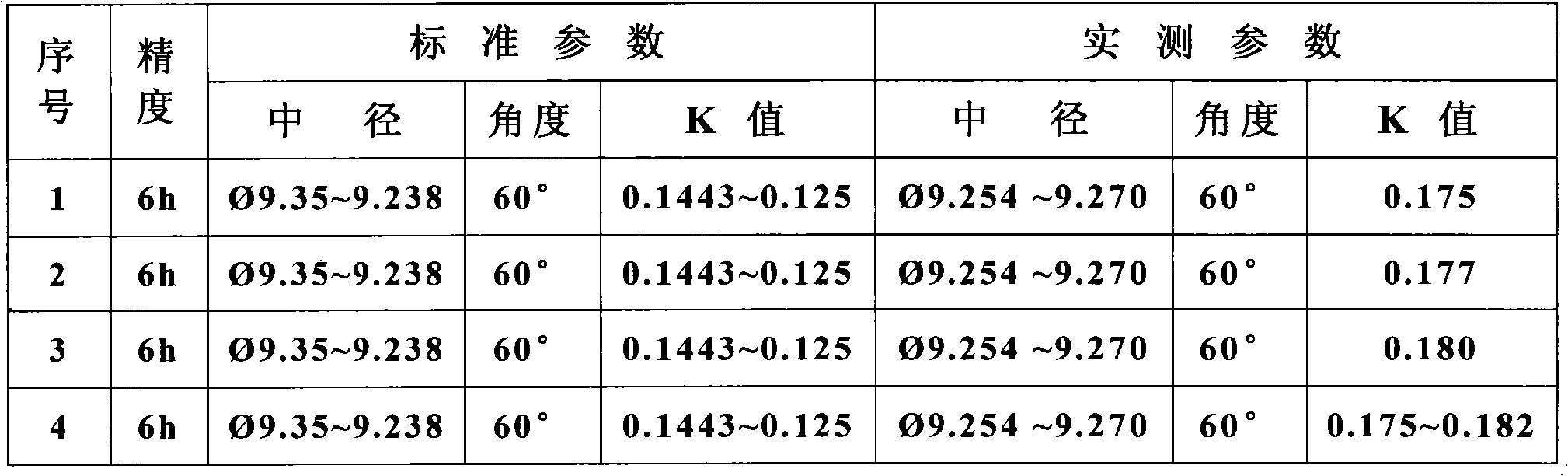

[0037] The three rolling wheels in the step (2) have the same thread tooth profile, pitch diameter and pitch, and the pitch angles of the pitch of the pitch diameter of the three rolling wheels are equal and on the same development line. These 3 rolling wheels should have a manufacturing precision above IT4 level.

[0038] In the above, the rolling method us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com