Five-layer coextrusion transfusion medicine packing film and manufacturing method thereof

A technology for packaging and pharmaceuticals, applied in the direction of transportation and packaging, packaging, wrapping paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

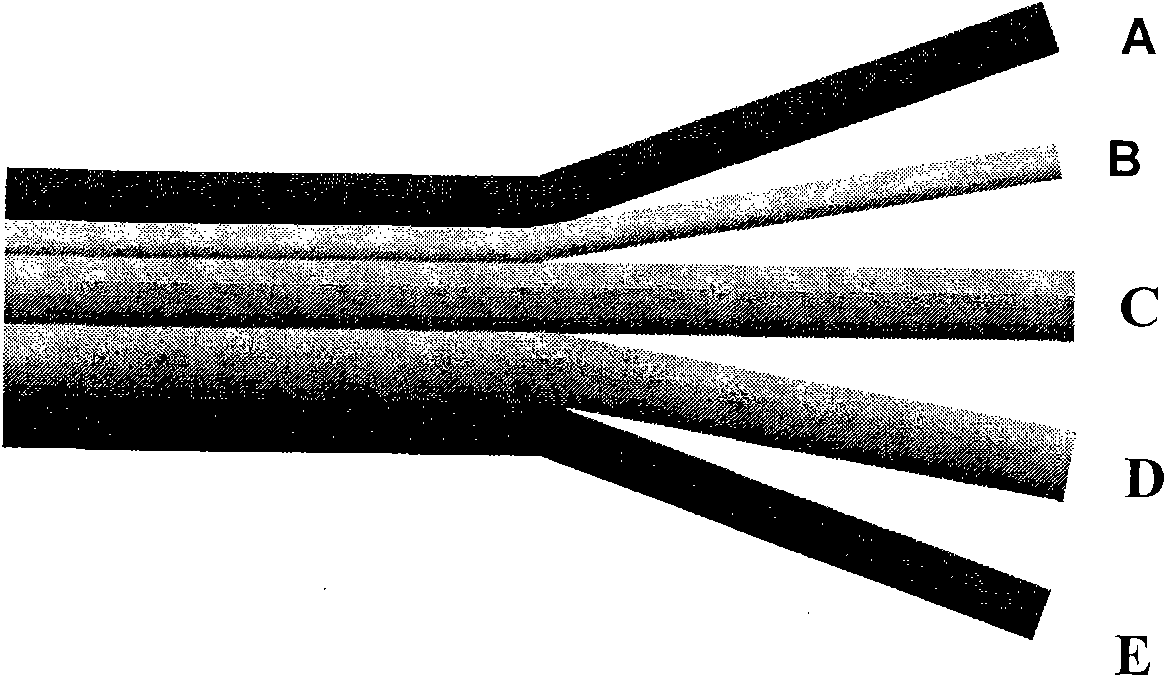

Image

Examples

Embodiment 1

[0051] The thickness of layer A is 10 μm, and the polyester is Ecdel 9965 produced by Eastman.

[0052] The thickness of layer B is 8 μm, and the constituent material is BYNEL2714 of DuPont Company, and the resin blended with it is Engage8003 of Dow, and the blending ratio is 90:10.

[0053] The thickness of layer C is 75 μm, the content of polypropylene is 30%, the content of polyethylene is 50%, and the content of SEBS is 20%. The PP material is Atofina's Z8453, the PE is Dow's Engage8003, and the suitable SEBS material is Kraton's G1650.

[0054] The layer D has a thickness of 90 μm, a polypropylene content of 60%, a polyethylene content of 30%, and a SEBS content of 10%. The PP material is Atofina's 3281, the PF is Versify2200, and the SEBS material is Kraton's G1652.

[0055] The thickness of the E layer is 15 μm, the content of polypropylene is between 75%, and the content of SEBS is 25%. The propylene / ethylene copolymer is Atofina's Z8453, and the SEBS material is Kr...

Embodiment 2

[0057] The thickness of layer A is 15 μm, and the polyester is soft polyester CP301 produced by Mitsubishi.

[0058] The thickness of layer B is 10 μm, and the constituent material is Orevac 18760 of Arkema, and the resin blended with it is Zales 7023 of Mitsubishi, and the blending ratio is 70:30.

[0059] The thickness of layer C is 70 μm, the content of polypropylene is 30%, the content of polyethylene is 50%, and the content of SEBS is 20%. The PP material is Mitsubishi's ZalesMC742, the PE is Dow's Engage8003, and the SEBS material is Kraton's G1651.

[0060] The layer D has a thickness of 95 μm, a polypropylene content of 60%, a polyethylene content of 30%, and a SEBS content of 10%. The PP material is Adflex Q100F of Basel1, the PE is Infuse9100, and the SEBS material is G1650 of Kraton.

[0061] The thickness of the E layer is 15 μm, the content of polypropylene is between 75%, and the content of SEBS is 25%. The propylene / ethylene copolymer is Adsyl 3C30F of Basell...

Embodiment 3

[0063] The thickness of layer A is 12 μm, and the polyester is Ecdel 9967 produced by Eastman.

[0064] The thickness of layer B is 10 μm, and the constituent material is Arkema's Orevac8760, and the resin blended with it is Basell Adflex Q100F, and the blending ratio is 75:25.

[0065]The thickness of layer C is 75 μm, the content of polypropylene is 70%, the content of polyethylene is 15%, and the content of SEBS is 15%. The PP material is Mitsubishi's Zales7023, the PE is Dow's Engage8003, and the SEBS material is Kraton's G1650.

[0066] The layer D has a thickness of 80 μm, a polypropylene content of 65%, a polyethylene content of 25%, and a SEBS content of 10%. The PP material is Atofina's 6232, the PE is Exceed2018CA, and the SEBS material is Kraton's G1675.

[0067] The thickness of the E layer is 20 μm, the content of polypropylene is between 75%, and the content of SEBS is 25%. The propylene / ethylene copolymer is Atofina's Z8453, and the SEBS material is Kraton's ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com