Mine restoration greening method

A technology for mines and mining areas, applied in the field of ecological restoration, can solve the problems affecting the greening effect of mine restoration, the increase of heavy metal content in the soil, and the influence of plant growth, etc., to reduce the poisonous effect, speed up the ecological reconstruction, and realize the greening effect of the mining area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0044] A preparation method of a heavy metal treatment agent comprises the following steps: mixing 35g of calcium-based bentonite, 10g of silicon dioxide, 30g of glucose, 8g of hydroxyethyl cellulose and 10g of cement.

preparation example 2-12

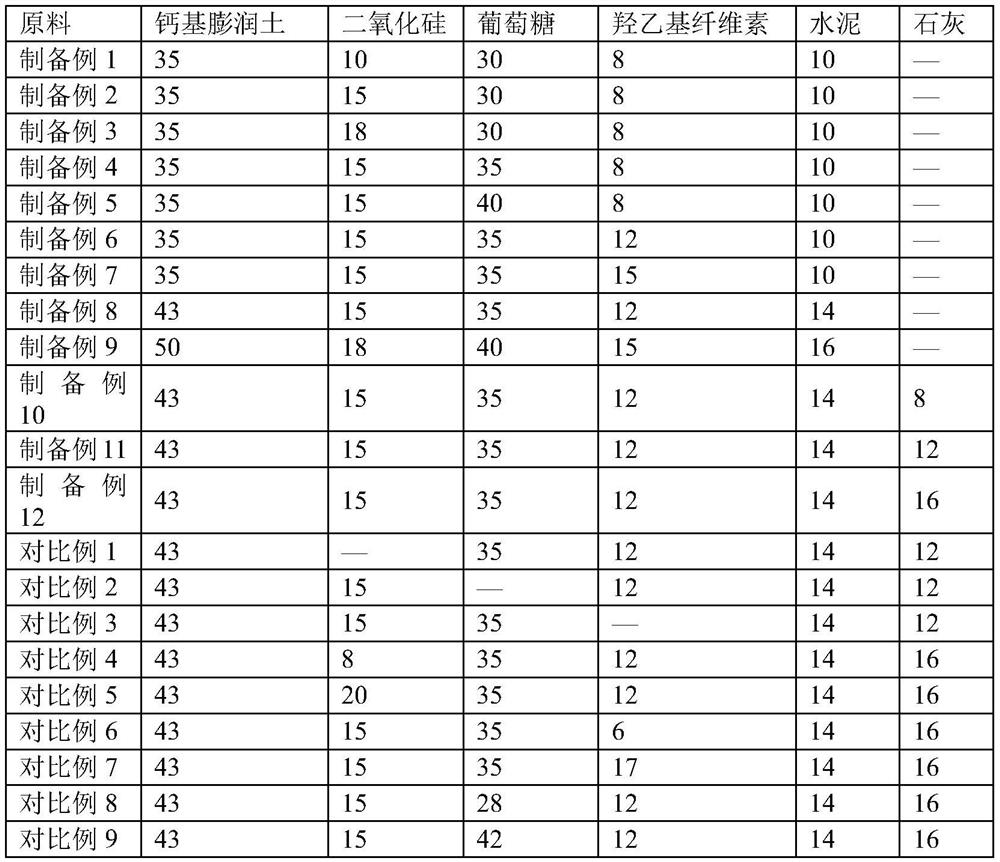

[0046] A preparation method of a heavy metal treatment agent is carried out according to the method in Preparation Example 1, except that it is carried out according to the ingredient list in Table 1 below.

[0047] Table 1:

[0048]

preparation example 13

[0061] A method for preparing a soil planting substrate, comprising the following steps: mixing 5kg of water-retaining agent, 50kg of organic fertilizer, 25kg of inorganic fertilizer, 150kg of soil and 12kg of calcium-based bentonite, wherein the water-retaining agent is selected from polyacrylamide water-retaining agent, and the organic fertilizer is selected from The mass ratio is 1:3:2 biogas manure, sheep manure and mineral source potassium fulvic acid, the inorganic fertilizer is urea, calcium magnesium phosphate fertilizer and ammonium bicarbonate with a mass ratio of 1:2:1.5, and the soil is selected from the green environment around the mining area soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com