Photocurable monomer containing active amine structure and preparation method thereof

A technology of active amine and photopolymerizable monomer, applied in the field of photocurable monomer containing active amine structure and its preparation, can solve the problems of oxygen inhibition, influence on coating surface performance, sample contamination, etc., to avoid migration, prevent Adverse effects, effects of good surface curing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

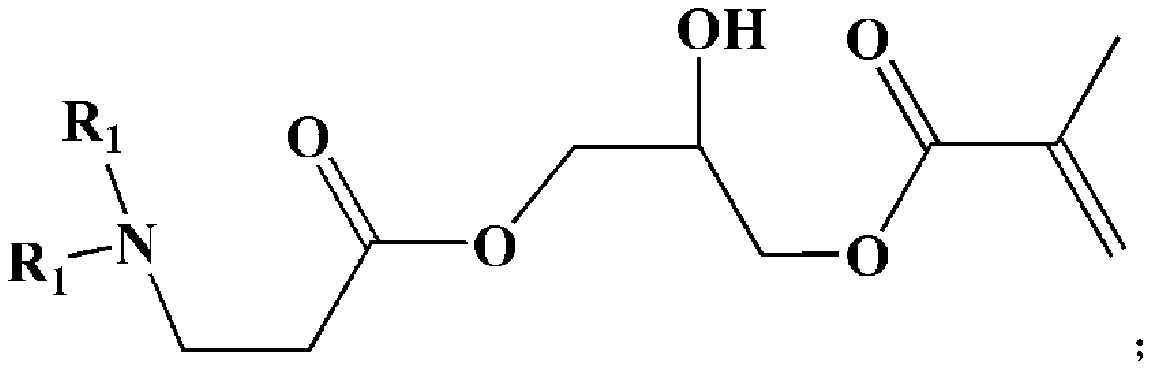

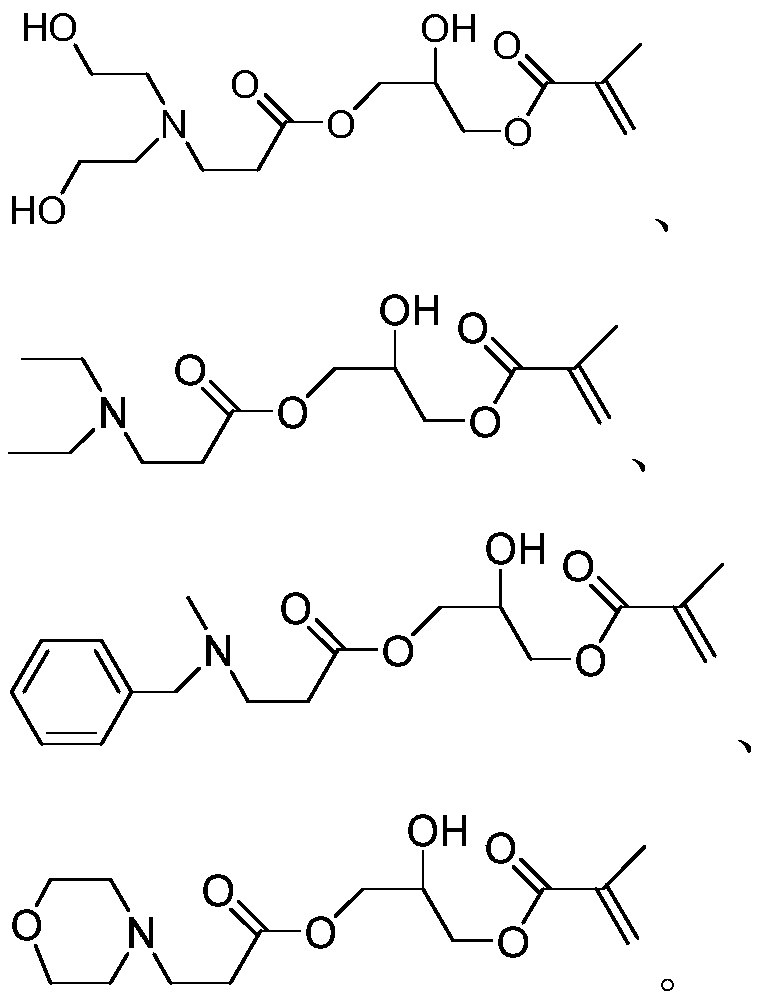

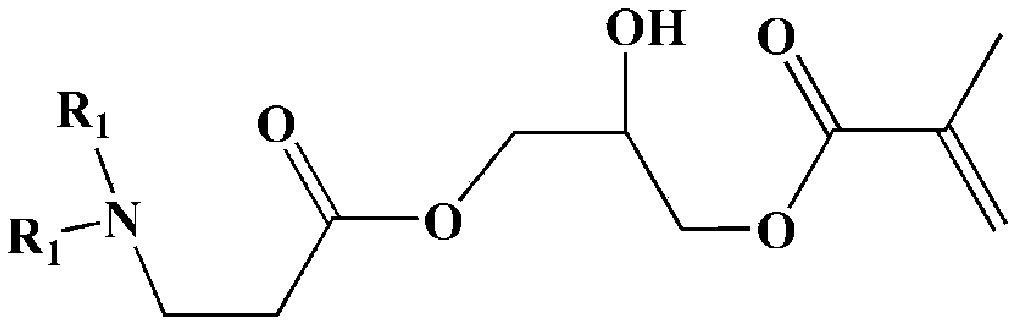

[0033] The reaction equation of the photopolymerizable monomer preparation process containing active amine is as follows:

[0034]

Embodiment 2

[0036] A preparation method of a photopolymerizable monomer containing an active amine structure, comprising the following steps:

[0037] (1) Weigh 64g of glycidyl methacrylate, add 3.0g of tetramethylammonium chloride and 0.1g of hydroxyanisole, and stir in a three-necked flask, heat up to 90°C, and use a constant-pressure dropping funnel to add to the reaction system Add 37.8g of acrylic acid dropwise to the mixture, after the dropwise addition, continue to react for 4h and then test the acid value, when the acid value is less than 10mg KOH / g, stop the reaction;

[0038] (2) After cooling, add 55 g of diethanolamine dropwise to the reaction system in an ice bath. After the dropwise addition, raise the temperature to 60° C. and continue the reaction for 2 hours;

[0039] (3) After the reaction finishes, cool down to room temperature, wash the product 2-3 times with deionized water, then wash 2-3 times with 1wt% NaOH aqueous solution, and finally wash with deionized water to ...

Embodiment 3

[0043] (1) Weigh 64g of glycidyl methacrylate, add 1.2g of tetrabutylammonium bromide, 0.5g of hydroxyanisole, and stir in a three-necked flask to raise the temperature to 110°C. Add 43.2g of acrylic acid dropwise in the solution, after the dropwise addition, continue to react for 4h and then test the acid value, when the acid value is less than 10mgKOH / g, stop the reaction;

[0044] (2) Add 63 g of diethanolamine dropwise to the reaction system under ice bath conditions, after the dropwise addition, raise the temperature to 80° C., and continue the reaction for 2 hours;

[0045] (3) After the reaction finishes, cool down to room temperature, wash the product 2-3 times with deionized water, then wash 2-3 times with 1wt% NaOH aqueous solution, and finally wash with deionized water to neutrality, transfer it to a beaker, Add an appropriate amount of anhydrous sodium sulfate, dry for 24 hours, and filter to obtain an acrylate photocurable monomer containing an active amine.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com