Water-based transparent wood flame retardant for inhibiting white bloom as well as preparation method and application of water-based transparent wood flame retardant

A fire retardant and wood technology, applied in wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of easy migration and precipitation, affect the appearance of wood, and affect the flame retardant performance, so that it is not easy to penetrate, improve migration resistance, reduce tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

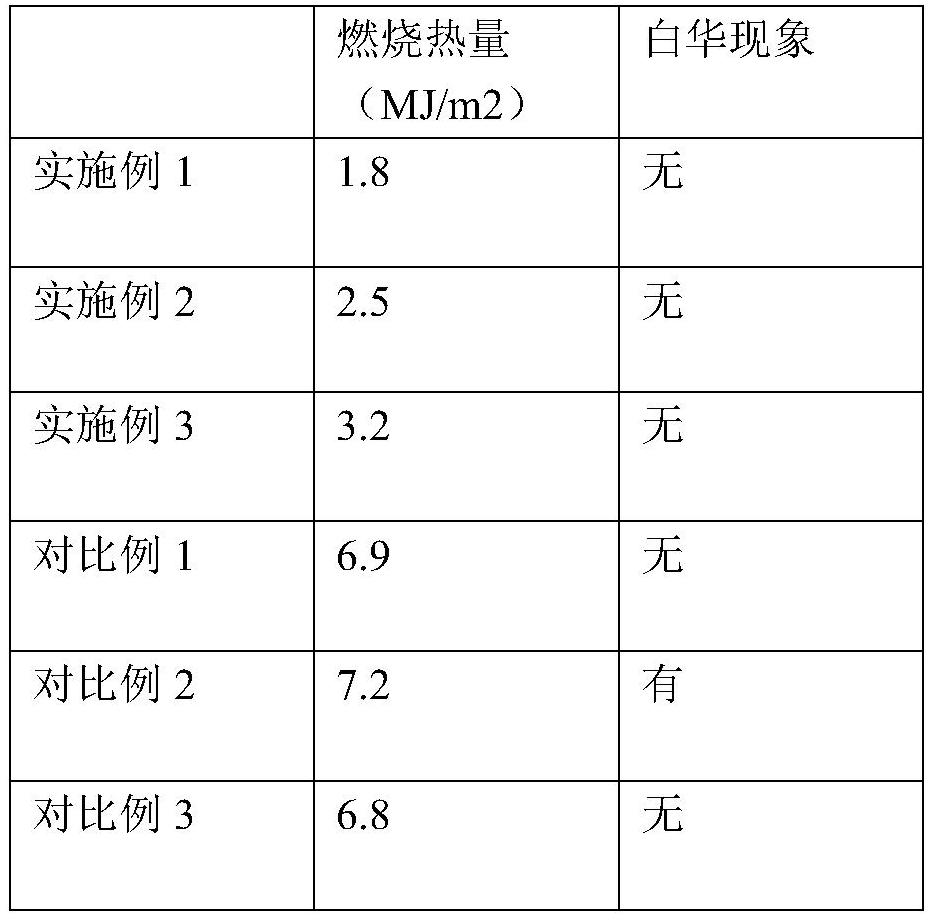

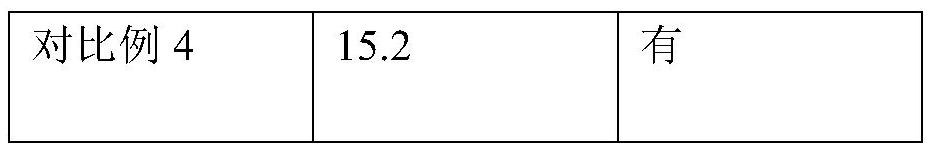

Embodiment 1

[0029] Put 7500g of 50% mass fraction of amino trimethylene phosphonic acid ATMP aqueous solution into the reactor, add 4250g of 25% mass fraction of ammonia water, mix uniformly and fully react and cool to room temperature to obtain the reaction solution, and mix 350g of ethylene glycol Amine, 250g of sodium hydroxide and 75g of surfactant sodium dodecylbenzenesulfonate were added to the liquid and stirred evenly to obtain 12425g of flame retardant for wood. The flame retardant for wood obtained in this example consists of an aqueous solution containing ATMP, ammonia, ethylenediamine and a surfactant.

Embodiment 2

[0031] Put 7500g of 61% mass fraction of hydroxyethylene diphosphoric acid HEDP aqueous solution into the reactor, add 4500g of 25% mass fraction of ammonia water, mix uniformly and fully react and cool to room temperature to obtain the reaction solution, then add 350g of trimethylamine , 250g of potassium hydroxide and 75g of surfactant sodium dodecylbenzene sulfonate were added to the liquid and stirred evenly to obtain 12675g of fire retardant for wood. The flame retardant for wood obtained in this example is composed of HEDP, ammonia water, trimethylamine, potassium hydroxide and surfactant aqueous solution.

Embodiment 3

[0033] The aminotrimethylene phosphonic acid (ATMP) aqueous solution of the mass fraction 50% of 7500g is put into reactor, the ammoniacal liquor of the mass fraction 25% that adds 4250g wherein mixes evenly and fully reacts and cools to room temperature and obtains reaction solution, then 200g Aniline, 150g catecholamines, 125g aluminum hydroxide, 125g magnesium hydroxide and 75g surfactant sodium dodecylbenzenesulfonate were added to the liquid and stirred evenly to obtain 12425g fire retardant for wood. The fire retardant for wood obtained in this embodiment is composed of amino trimethylene phosphonic acid (ATMP), ammonia water, aniline, catecholamine, aluminum hydroxide, magnesium hydroxide and surfactant aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com