Pre-charging method of lithium ion battery with cobalt acid lithium as positive active material

A cathode active material, lithium-ion battery technology, applied in secondary battery charging/discharging, secondary battery, secondary battery repair/maintenance, etc., can solve problems such as low production efficiency, improve production efficiency, shorten pre-charging effect of time and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

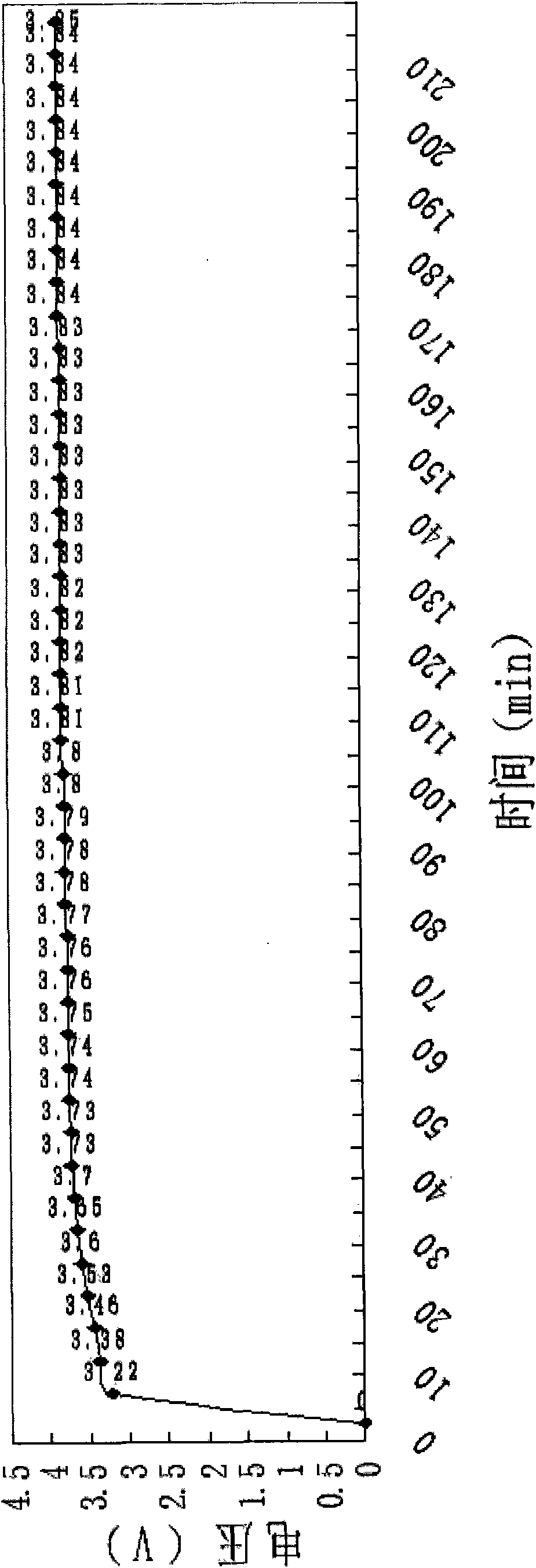

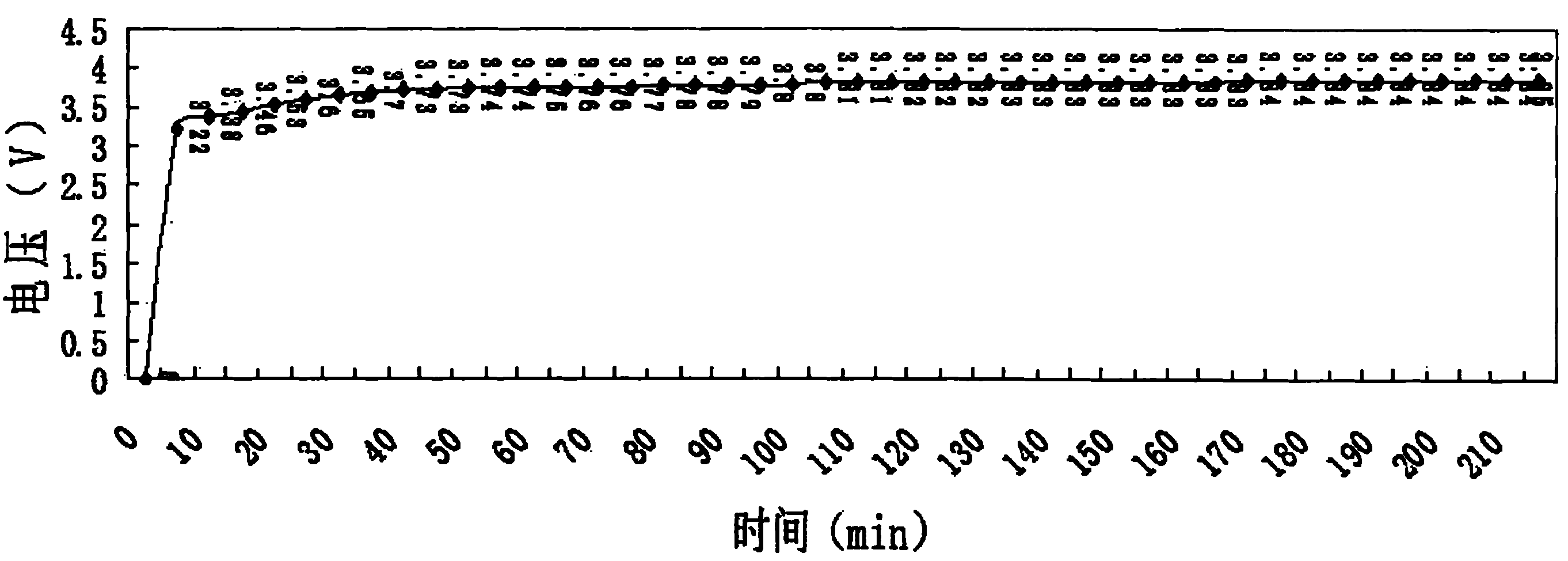

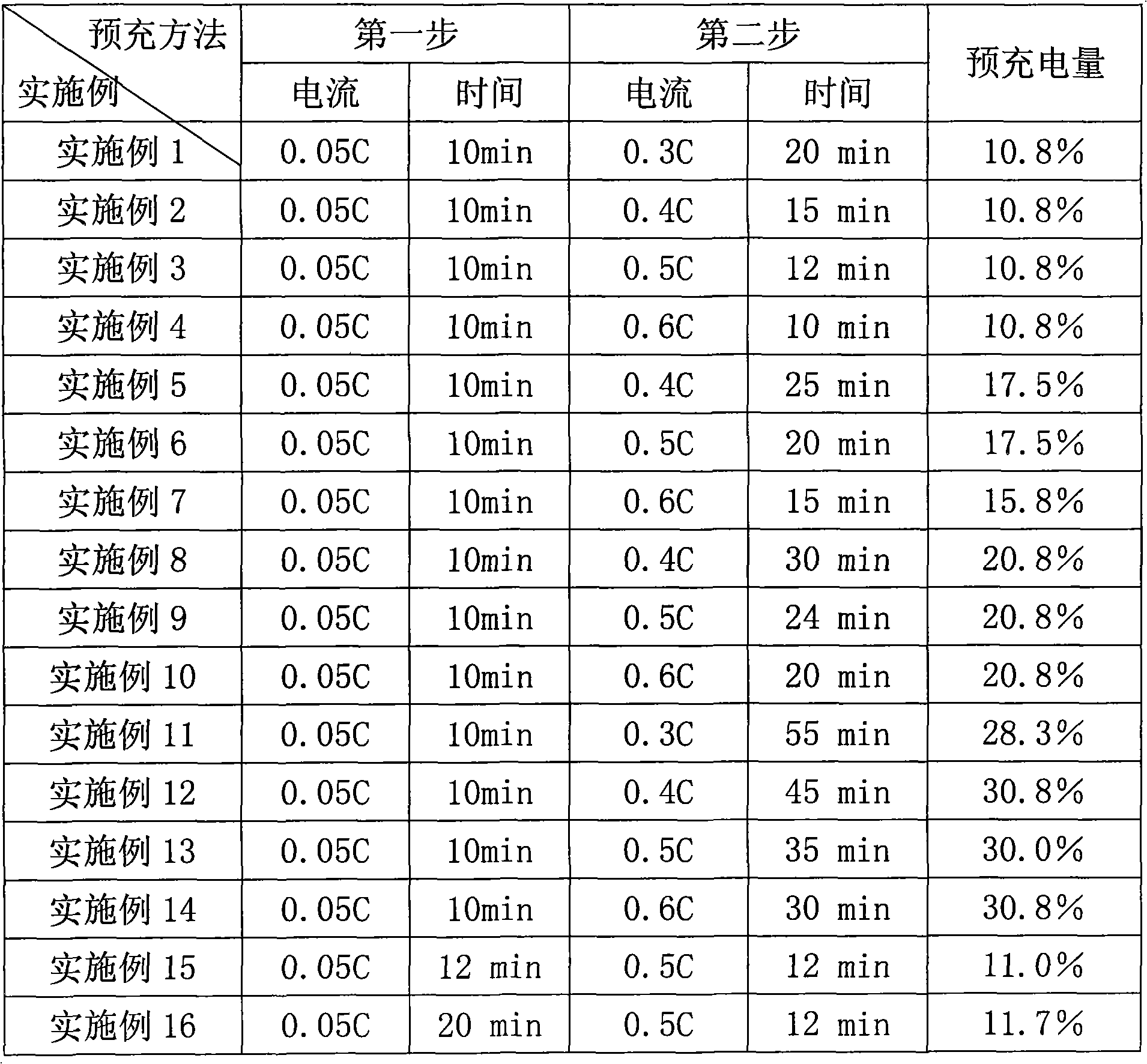

[0023] The specific process steps are as follows: first inject liquid into the sample cell, and the liquid injection volume is 85% of the process requirement, then age the cell for 1 to 2 hours, and then go to the pre-charging cabinet to pre-charge at 0.05C, 10min; 0.3C, 20min The method is to precharge, then go to the cabinet to measure the voltage, refill 15% of the liquid again, squeeze the battery cell and complete the sealing, the above process steps are all carried out in the same temperature and humidity environment, temperature ≤ 26 ° C; humidity ≤ 2% . At room temperature, measure the size of the sealed battery cell after cleaning, and measure the battery cell after aging for 6 days. The capacity classification system is based on the parameters shown in Table 2. Investigate its capacity, internal resistance, 3.92V size and cycle performance test, the results are shown in Table 3.

[0024] Among them, the purpose of testing the voltage is to investigate whether there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com