Process for treating aluminum substrate acid cleaning and alkaline cleaning waste liquid

A waste liquid treatment and substrate acid technology, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high treatment cost, high treatment cost and high investment, and achieve Significant social benefits, reduced processing costs, and scientific and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

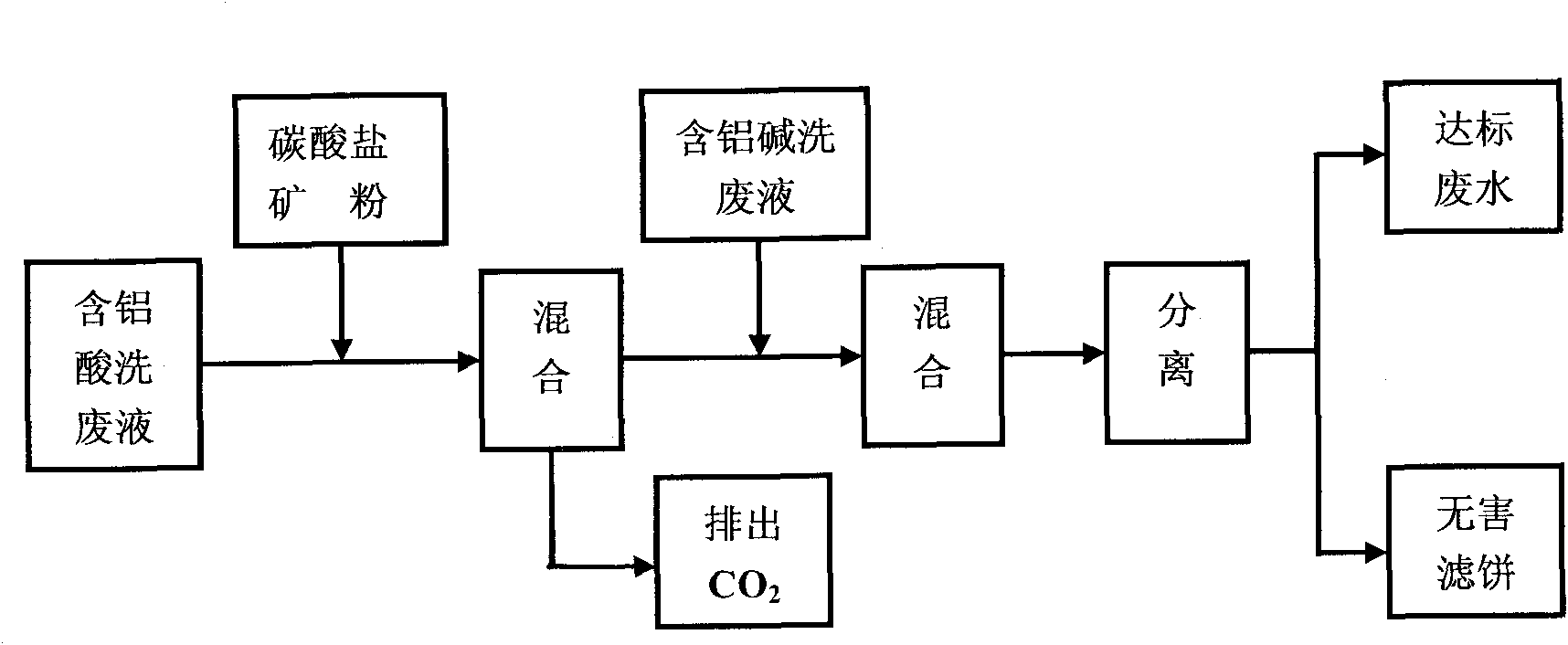

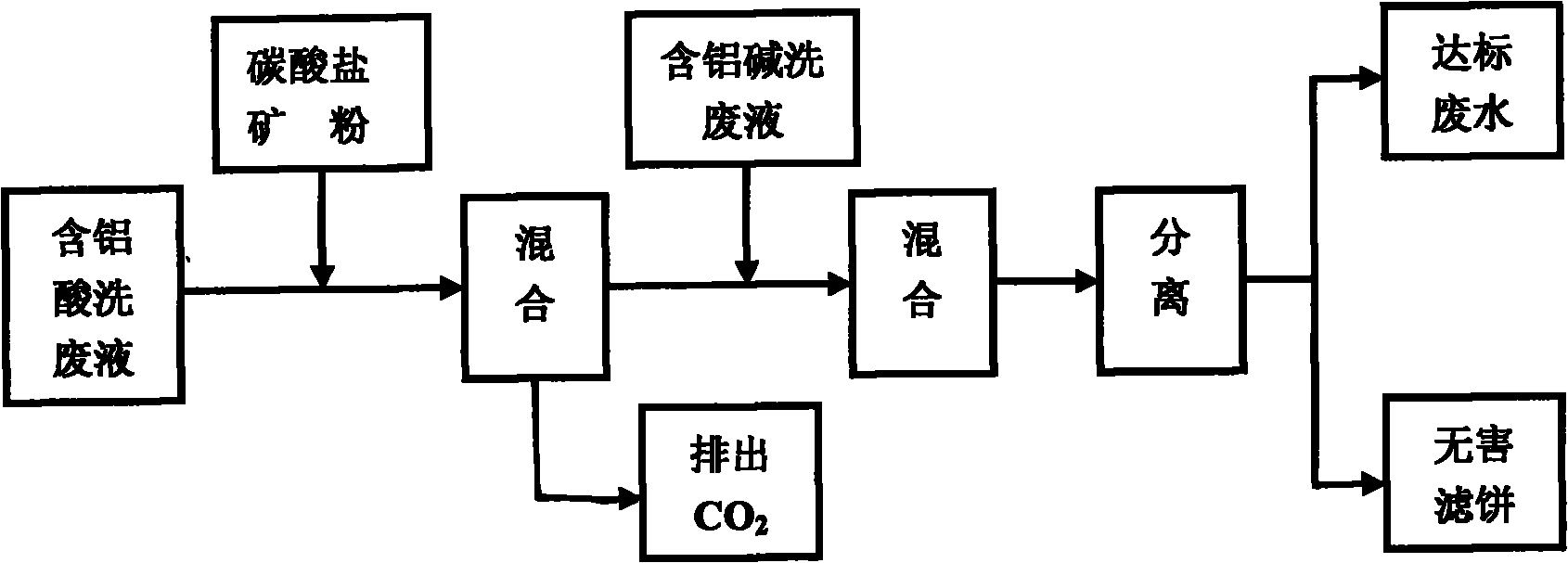

[0013] In conjunction with the accompanying drawings and embodiments, the specific process steps of the process of the present invention are further described.

[0014] The embodiment of the process for the treatment of aluminum substrate pickling and alkaline cleaning waste liquid in the present invention, see figure 1 , the following process steps are adopted: first add an appropriate amount of carbonate ore powder to the entire amount of aluminum-containing pickling waste, mix for metathesis reaction, and continuously stir throughout the whole process to fully discharge CO 2 , so that the pH reaches 3-5; then add the entire amount of aluminum-containing alkali washing waste liquid, mix and carry out neutralization reaction, so that the pH reaches 6-9, and separate the formed suspension to separate the waste water and aluminum hydroxide filter cake.

[0015] In the above steps, the amount of carbonate ore powder added has been calculated in advance, or adjusted according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com