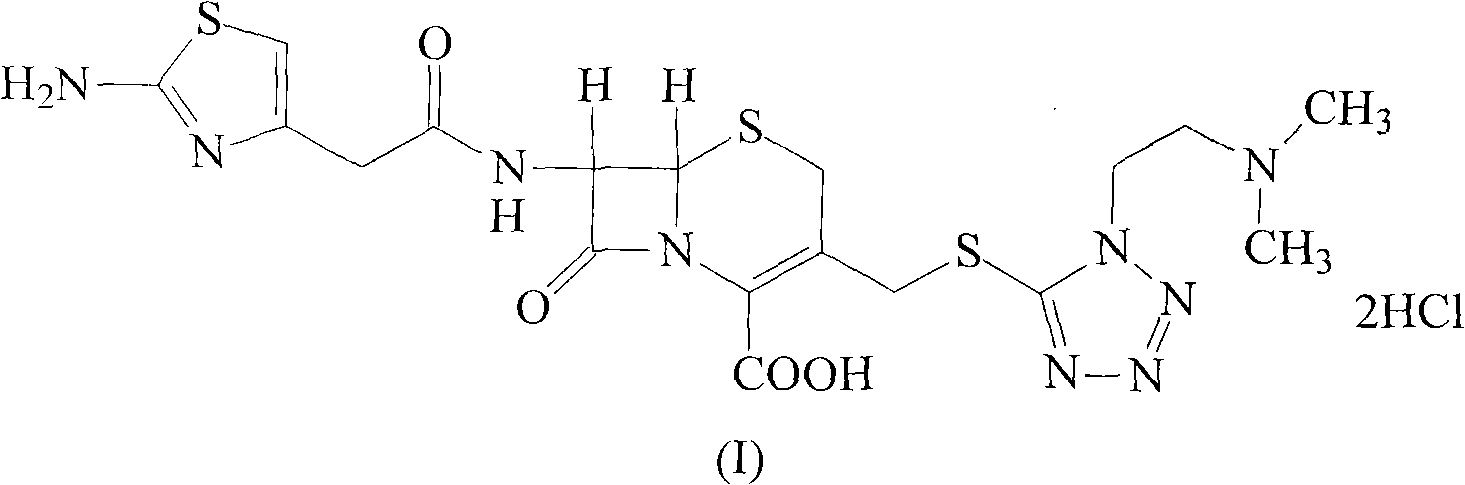

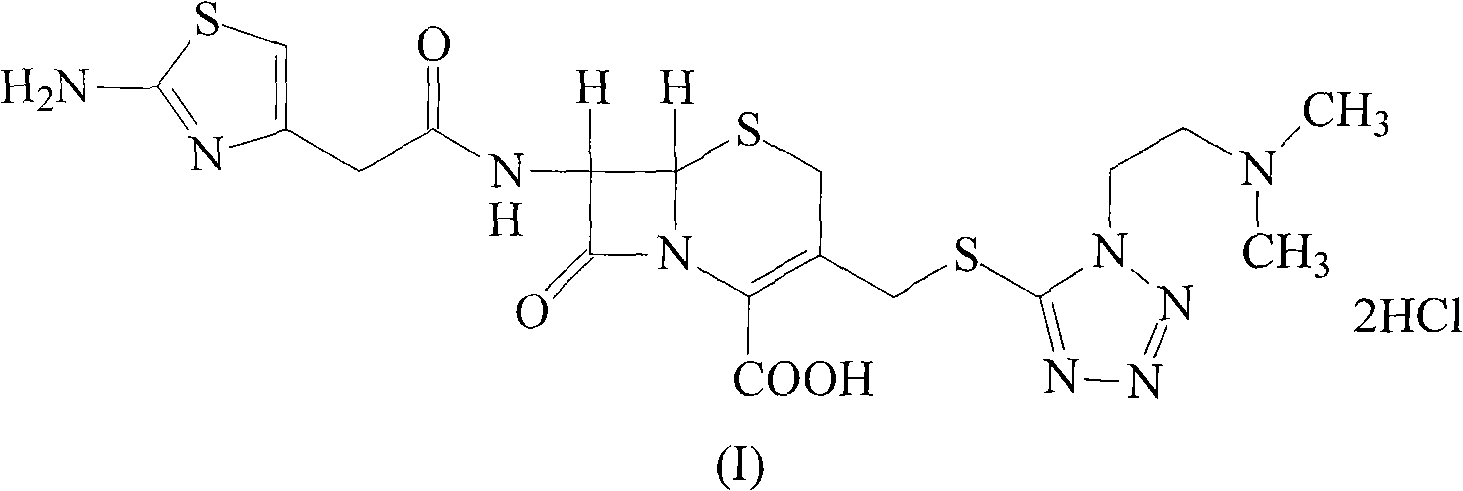

High-purified cefotiam hydrochloride compound

A technology of cefotiam hydrochloride and cefotiam, which is applied in the field of medicine, can solve problems such as difficult operation, low yield and product purity, and cumbersome reaction steps, and achieve the effects of low cost, improved purity, and optimized product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The refining of embodiment 1 cefotiam hydrochloride

[0025] (1) Dissolve 100g cefotiam hydrochloride in 1500ml water, add 2% sodium hydroxide solution to pH 7.2, stir and react for 30 minutes, then add D1300 type macroporous adsorption resin, stir and adsorb at room temperature for 20 minutes, use purification Purify by water elution, collect the eluent, and filter;

[0026] (2) In the filtrate, add dropwise the hydrochloric acid solution of 2mol / L to pH value 5, then add ethanol 1500ml, separate out insoluble matter, stir and react at room temperature for 60 minutes, filter, and dry under reduced pressure at 50°C to obtain 93.0g of cefotiam hydrochloride, The yield was 93.0%, and the HPLC purity was 99.7%.

Embodiment 2

[0027] The refining of embodiment 2 cefotiam hydrochloride

[0028] (1) 100g cefotiam hydrochloride was dissolved in 1500ml water, added 10% sodium bicarbonate solution to a pH value of 8.5, stirred and reacted for 60 minutes, then added BS-55 type macroporous adsorption resin, stirred and adsorbed at room temperature for 30 minutes, Elute and purify with purified water, collect the eluent, and filter;

[0029] (2) Add dropwise 8mol / L hydrochloric acid solution to the pH value of 4 in the filtrate, then add isopropanol 1500ml, precipitate insoluble matter, stir and react at room temperature for 90 minutes, filter, and dry under reduced pressure at 45°C to obtain cefotiam hydrochloride 91.6 g, the yield is 91.6%, and the HPLC purity is 99.6%.

Embodiment 3

[0030] The refining of embodiment 3 cefotiam hydrochloride

[0031] (1) Dissolve 100g cefotiam hydrochloride in 1500ml water, add 5% sodium carbonate solution to a pH value of 7.8, stir and react for 50 minutes, then add D1300 type macroporous adsorption resin, stir and adsorb at room temperature for 30 minutes, use purified water Elution and purification, collecting the eluent, and filtering;

[0032] (2) in the filtrate, dropwise add the hydrochloric acid solution of 4mol / L to pH value 4.5, then add ethanol 1500ml, separate out insoluble matter, stir and react at room temperature for 80 minutes, filter, and dry under reduced pressure at 40°C to obtain cefotiam hydrochloride 92.2g, The yield was 92.2%, and the HPLC purity was 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com