Improver for lubricating performance of low-sulfur diesel oil and preparation process thereof

A lubricating performance, low-sulfur diesel technology, applied in the field of diesel anti-wear agents, can solve problems such as high viscosity, inconvenient practical application, and poor use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

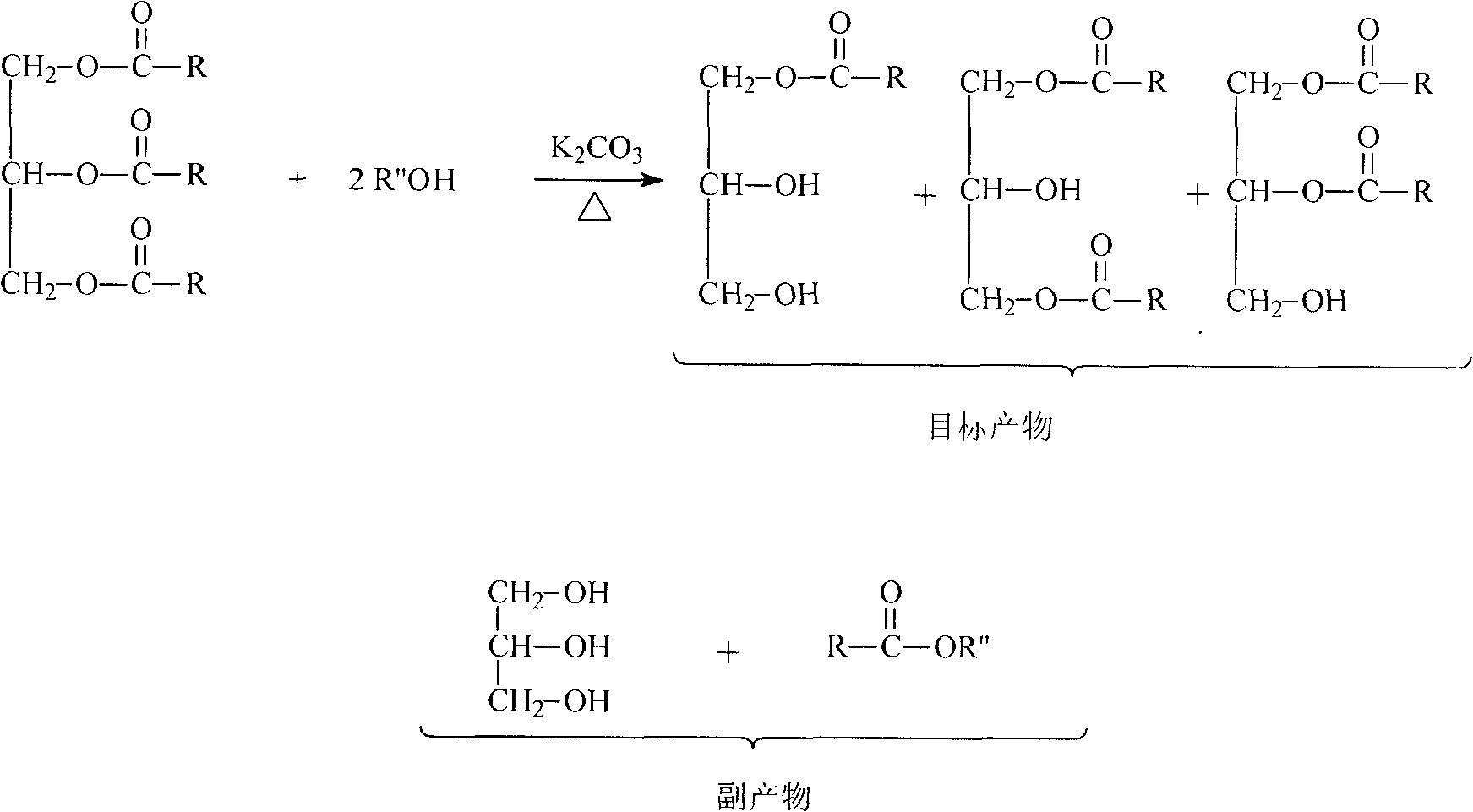

[0024] The preparation process of the low-sulfur diesel lubricity improver comprises the following steps:

[0025] (1) Synthesis of a mixture of monoglycerides and diglycerides: take natural oils and alcohols with a molar ratio of 1:1 to 2, and place them together with an inorganic alkali catalyst in a container equipped with an electric stirrer, a thermometer, and a reflux condenser. In the reactor, heat and stir to raise the temperature to 50-200°C and react for 1-20 hours to realize incomplete transesterification reaction. After cooling to room temperature and settling for 2-8 hours, a small amount of by-products settled at the bottom is separated by phase separation. The product glycerol and the regenerated catalyst can be recovered to obtain a mixture of monoglycerides and diglycerides. The reaction formula is as follows:

[0026]

[0027] It is compounded with dimer acid at a weight ratio of 1:0.2-0.8 to obtain a low-sulfur diesel lubricating performance improver.

...

Embodiment 1

[0038] A low-sulfur diesel lubricity improver, consisting of the following components: (A) a mixture of monoglycerides and diglycerides; (B) dimer acid; characterized in that: component (A) monoglycerides and diglycerides The weight ratio of ester mixture to component (B) dimer acid was 1:0.33.

[0039] A preparation process of a low-sulfur diesel lubricity improver, characterized in that: the preparation process comprises the following steps:

[0040] (1) Synthesis of a mixture of monoglycerides and diglycerides: take 182g (0.214mol) of soybean oil (average molecular weight: 850) and 23.8mL ethylene glycol (0.427mol) with a molar ratio of about 1:2, and 0.5g K 2 CO 3 Put them together in a reactor equipped with an electric stirrer, a thermometer, and a reflux condenser, heat and stir to raise the temperature to 150°C, react for 2 hours, cool to room temperature, settle for 5 hours, and separate out the bottom by phase separation. A small amount of by-product glycerin and c...

Embodiment 2

[0044] A low-sulfur diesel lubricity improver, consisting of the following components: (A) a mixture of monoglycerides and diglycerides; (B) dimer acid; characterized in that: component (A) monoglycerides and diglycerides The weight ratio of ester mixture to component (B) dimer acid was 1:0.43.

[0045] A preparation process of a low-sulfur diesel lubricity improver, characterized in that: the preparation process comprises the following steps:

[0046] (1) Synthesis of a mixture of monoglycerides and diglycerides: get 193g (0.214mol) of peanut oil (average molecular weight is 900) and 32.47g 1,3-propanediol (0.427mol) with a molar ratio of about 1:2, and 0.5 g Na 2 CO 3 Put them together in a reactor equipped with an electric stirrer, a thermometer, and a reflux condenser, heat and stir to raise the temperature to 150°C, react for 2 hours, cool to room temperature, settle for 5 hours, and separate out the bottom by phase separation. A small amount of by-product glycerin and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com