BE rust inhibitor based method and device for restoring electroosmotic salt polluted buildings

A repair method and rust inhibitor technology, which is applied in the repair field of salt-contaminated structures, can solve problems such as difficult construction, high cost, and easy recurrence, and achieve the effects of reducing raw material costs, cost reduction, and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

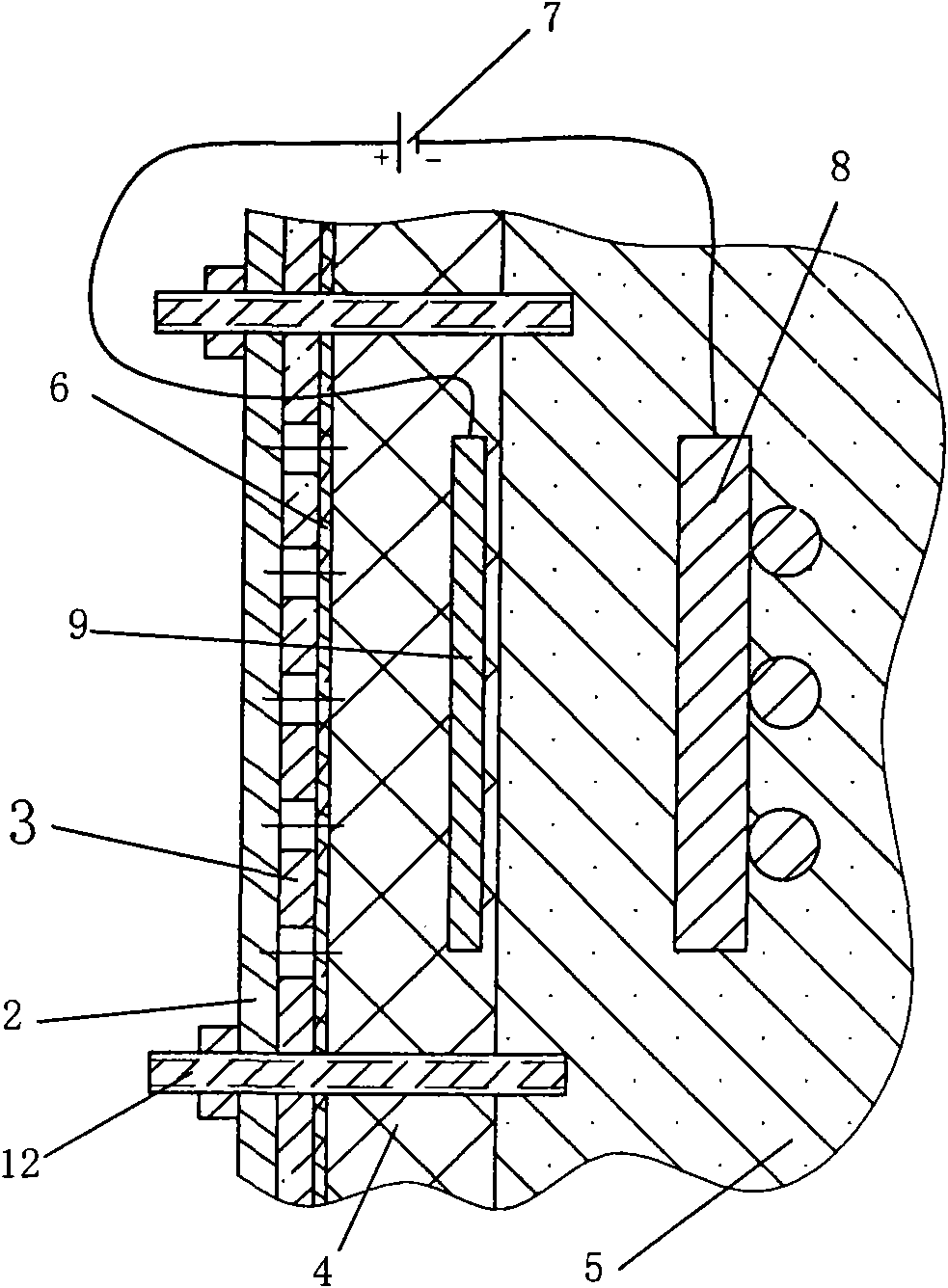

[0037] A kind of restoration method based on BE rust inhibitor electroosmotic salt pollution structure, it comprises the following steps:

[0038] The first step is to fix the steel mesh used as the anode material on the surface of the structure. The total cross-sectional area should be able to ensure the safe passage of the required current, and its corrosion consumption should be considered;

[0039] In the second step, a rust inhibitor-electrolyte retention and / or circulation system is set on the surface of the structure, covering the steel mesh as the anode material, and injecting the electrolyte (such as Ca(OH) 2 , LioH, NaCO 3 , NaOH aqueous solution, etc.) and BE rust inhibitor. The amount of rust inhibitor added is 3-30% by volume, which is determined according to the concentration of chloride ions in the concrete, the total surface area of the steel bars, and the electrification time. During specific construction, the first step and the second step can be reversed...

Embodiment 2

[0057] A kind of electroosmosis restoration method based on polluting structure with BE rust inhibitor electroosmosis salt, it comprises the following steps:

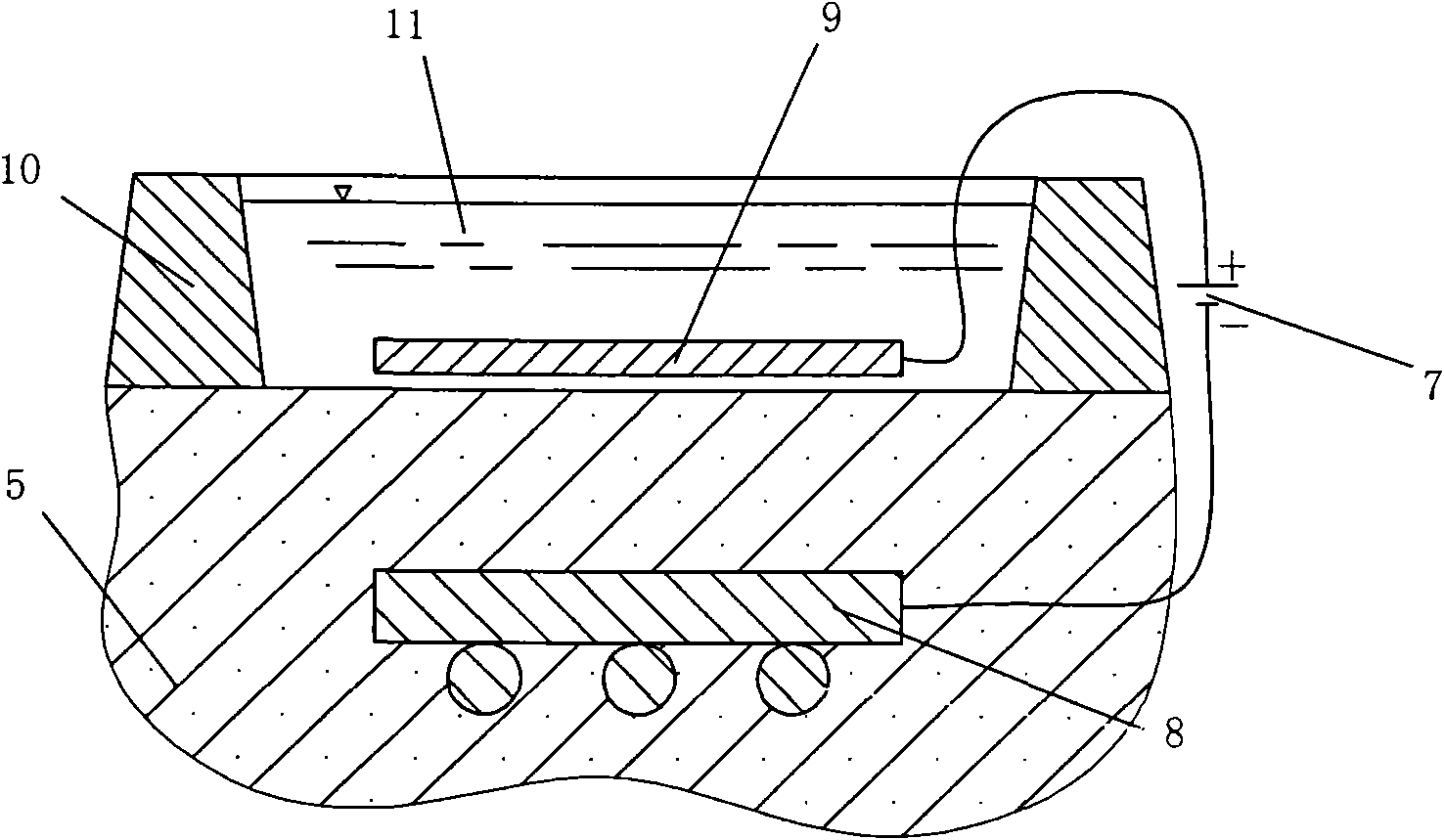

[0058] The first step is to make an assembly sheet combining flexible water-absorbing material and anode metal (any one of steel mesh, stainless steel, copper, platinum-plated titanium and MMO grid can be used). The assembly sheet is composed of waterproof membrane (cloth), water-absorbing material (non-woven fabric, sponge, foam material, etc.), flexible plastic net, and the anode metal material is worn in the plastic net. The anode is connected by plastic rivets, pressure strips, plastic grids, etc. The flexible assembly sheet is fixed on the concrete surface. Each flexible assembly sheet is provided with an anode material lead joint.

[0059] In the second step, the electrolyte (such as Ca(OH) 2 , LioH, NaCO 3 , NaOH aqueous solution, etc.) and BE rust inhibitor. The amount of rust inhibitor added is 3-30% by vol...

Embodiment 3

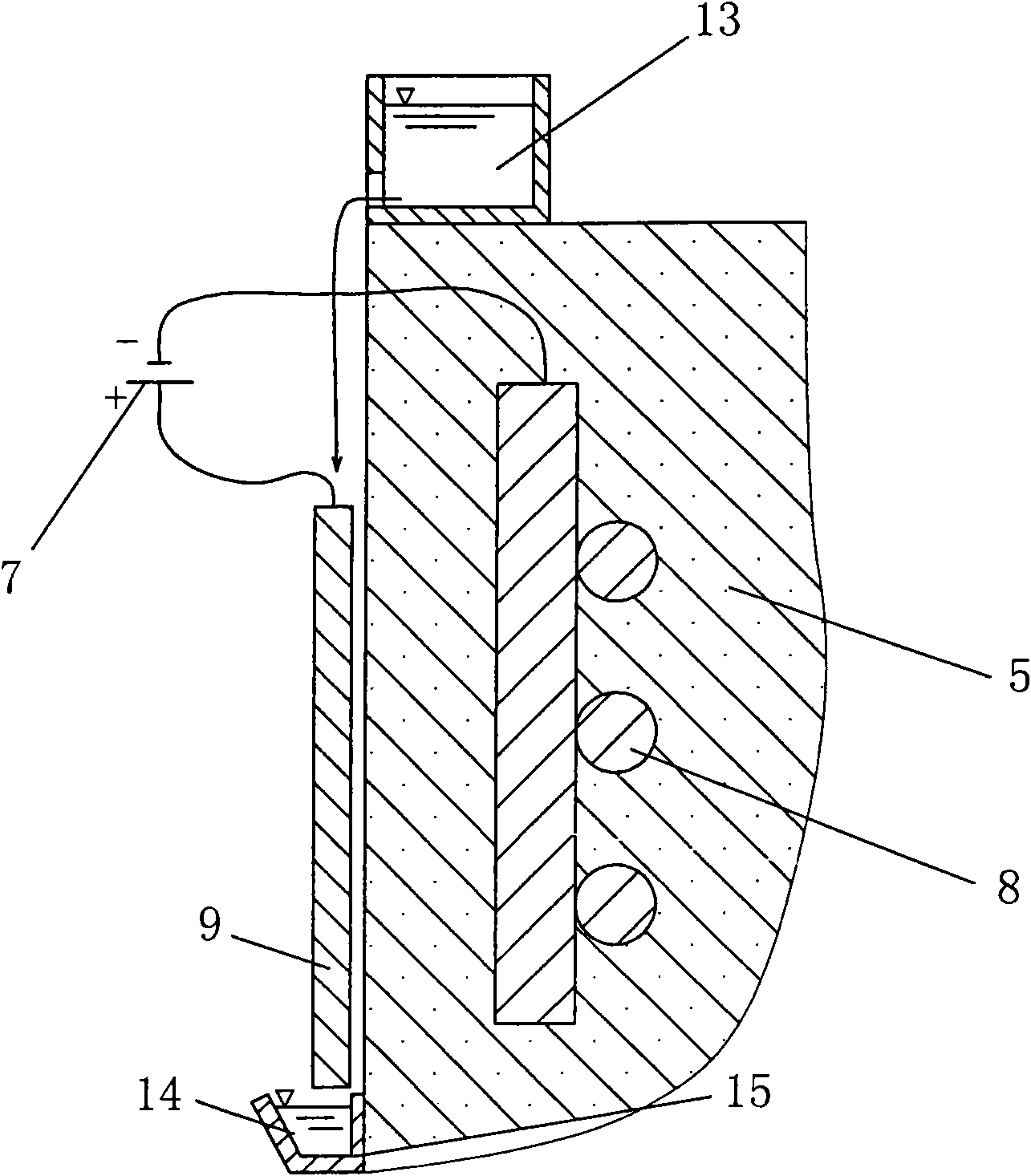

[0062] The difference between this embodiment and Embodiments 1 and 2 is that the rust inhibitor-electrolyte maintenance circulation system is mainly composed of an upper water tank, a lower water tank and a circulation pump. 7 connected, the upper water tank is provided with a water outlet, the electrolyte flowing out of the water outlet is poured on the surface of the anode material, the upper water tank and the lower water tank are connected by a connecting pipe and a circulation pump, so that the rust inhibitor and electrolyte of the upper water tank After flowing through the surface of the anode, it falls into the lower water tank, and is pumped to the upper water tank in time, and the cycle is repeated. The rest are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com