Large-scale garbage incinerator

A waste incinerator, a large-scale technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as insufficient combustion, affecting the long-term stable operation of waste incinerators, reducing the flow area of overhead flue, etc., to achieve reduction Fly ash deposition, beneficial to the effect of long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

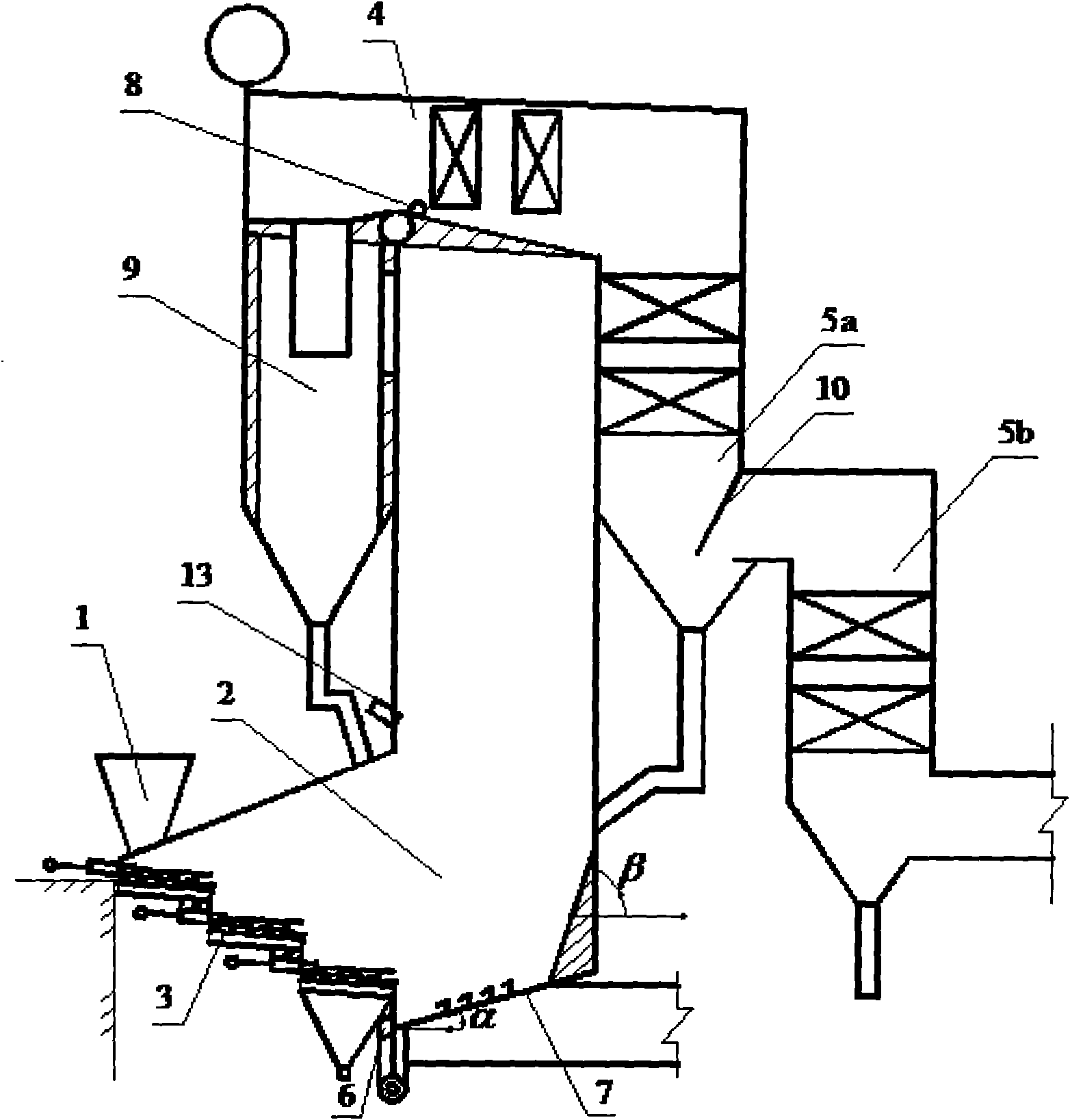

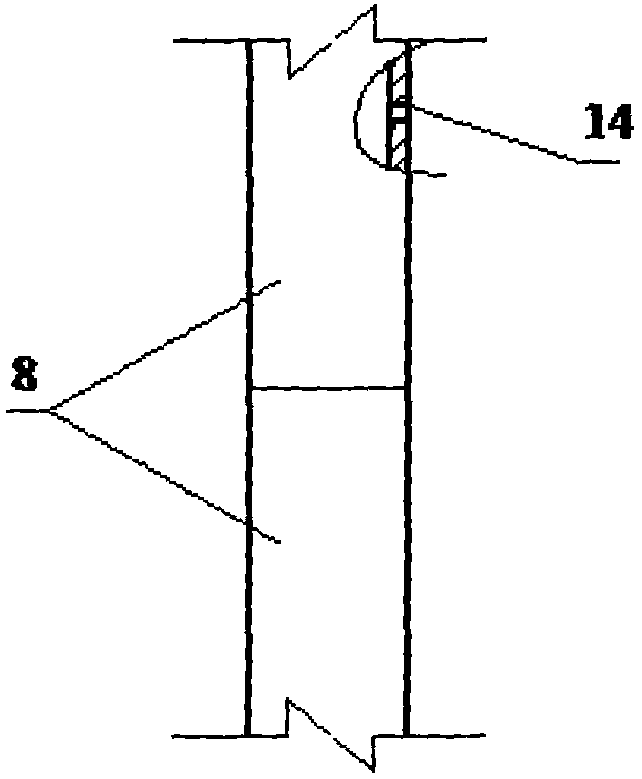

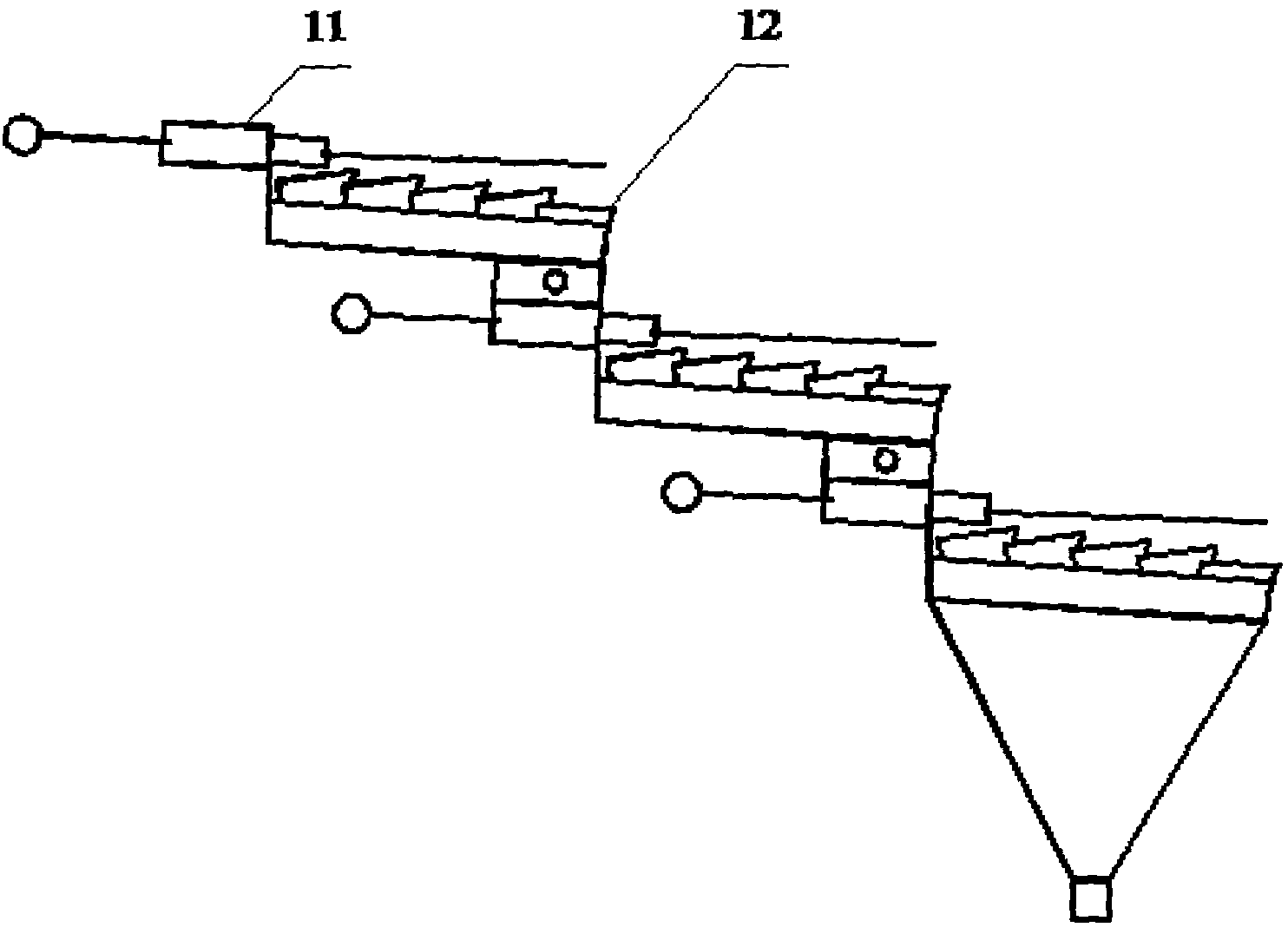

[0014] A large-scale incinerator, including a garbage hopper 1, a furnace 2, a garbage preheating and drying device 3, an overhead flue 4, a first-level tail shaft flue 5a, a second-level tail shaft flue 5b, a bed slag outlet 6, an inclined Type air distribution plate 7, cyclone separator 9 etc. The garbage preheating and drying device is arranged at the front end of the furnace 2 of the incinerator. In a large-scale garbage incinerator, the garbage preheating and drying device is arranged in two or three stages, and the garbage hopper 1 is connected to the garbage preheating and drying device in the frontmost stage. Garbage enters the garbage preheating drying device 3 from the garbage hopper 1, and enters the furnace 2 for burning after being fully dried. The air distribution plate 7 of the incinerator is inclined to the front end of the furnace, and the inclination angle α is 20-50°. The front wall of the furnace 2 (the furnace wall on the side connected to the garbage pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com