Nanomanipulation method for compounding laser near-field optical tweezers and AFM probe

A nano-manipulation and near-field light technology, applied in scanning probe technology, scanning probe microscopy, measurement devices, etc. Field fiber probe low-pass optical efficiency and other issues, to achieve the effect of convenient optical trap position and intensity, balance external interference force, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

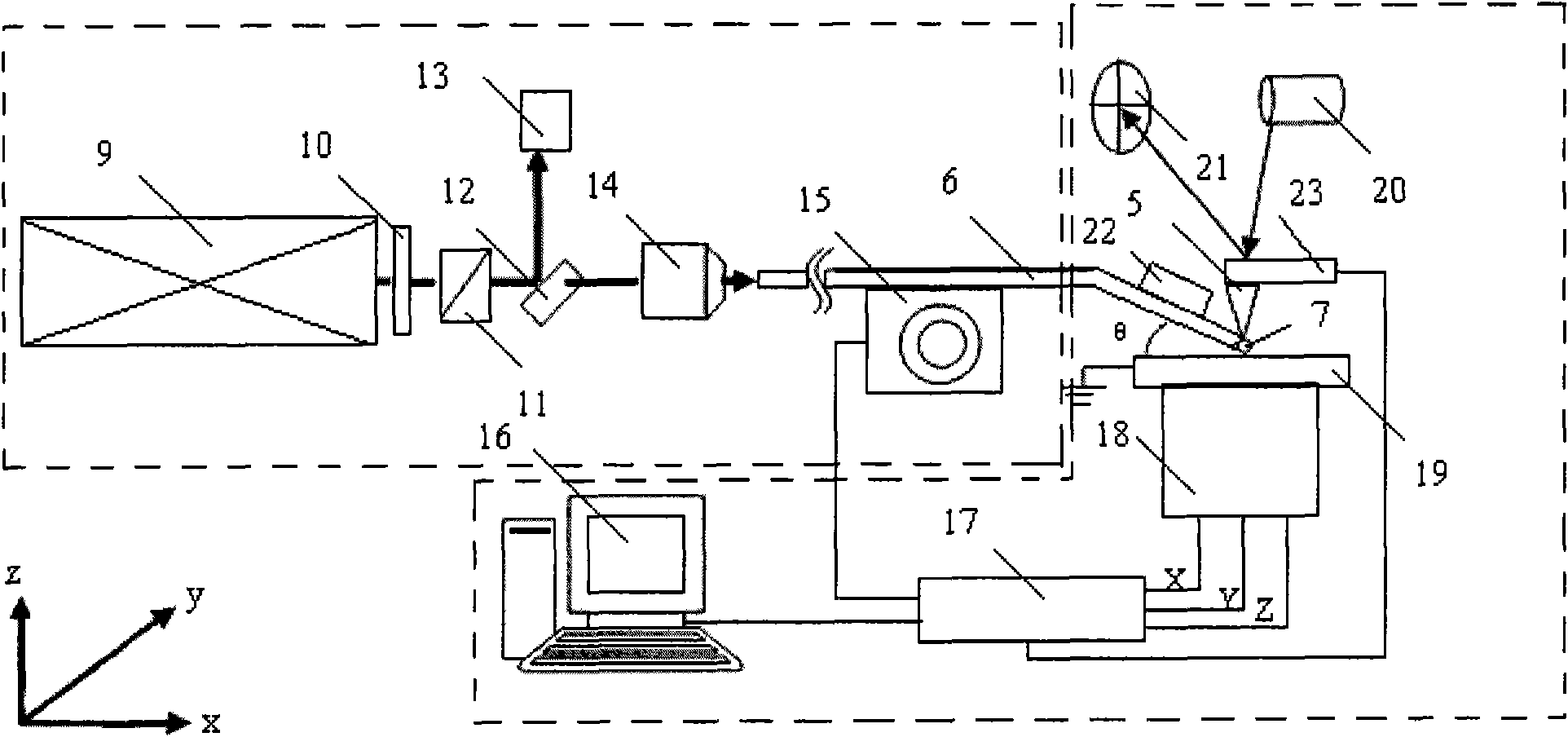

[0039] Embodiment 1: The operation of nanoparticles is realized by using a nano-manipulation method in which a single-fiber probe-type near-field optical tweezers is combined with an AFM probe.

[0040] The structure diagram of the method is as follows image 3 shown, combined with image 3 The specific steps of the composite nano-operation method are described in detail as follows:

[0041] The output laser light of the He-Ne laser 9 passes through the half-wave plate 10 and splits out a beam of light which is monitored by the power detection joule meter 13 , and then enters the fiber probe 6 from the fiber coupler 14 . First, the AFM probe 5 is approached to the sample by using the scanning micro-feeding system of the AFM, and the single nanoparticle 7 is precisely positioned, and then the three-dimensional adjustment table 15 is controlled by the feedback information generated by the distance measurement controller 22 to drive the optical fiber probe 6 to make it The AFM ...

Embodiment 2

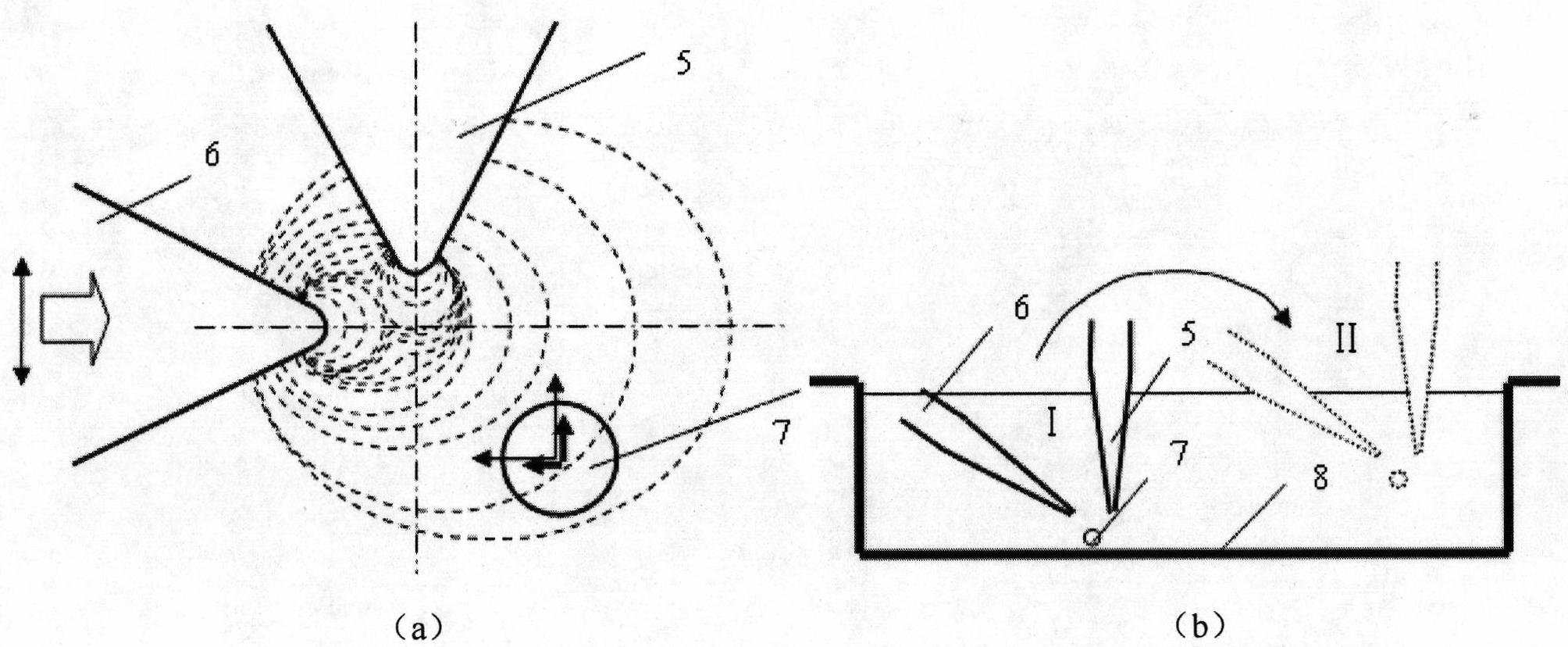

[0042] Example 2: Complicated three-dimensional operations are performed by using a double-fiber probe-type near-field optical tweezers combined with an AFM probe.

[0043] The principle structure of the method is as follows Figure 4 shown, combined with Figure 4 The specific steps of the complex three-dimensional operation method are described in detail as follows:

[0044] Firstly, the coarse adjustment system of AFM is used to roughly select the sample area with suitable density and dispersion, and then the scanning micro-feeding system of AFM is used to bring the AFM probe 5 close to the nanoparticle 7 to precisely position the single nanoparticle 7. After the selected location of the nanoparticles 7 is determined, the distance between the fiber probe 6 and the AFM probe 5 is reduced to the near-field range by using the three-dimensional adjustment stage 15, and the distance measuring controller 22 is used to keep the two at a certain distance during the micro-approxima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com