Thin film transistor array substrate

A technology of thin film transistors and array substrates, which is applied in the field of liquid crystal display, can solve the problems of increasing laser cutting process, complicated testing process, and reliability problems, so as to improve production efficiency and product yield, improve reliability, and avoid electrical problems. problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

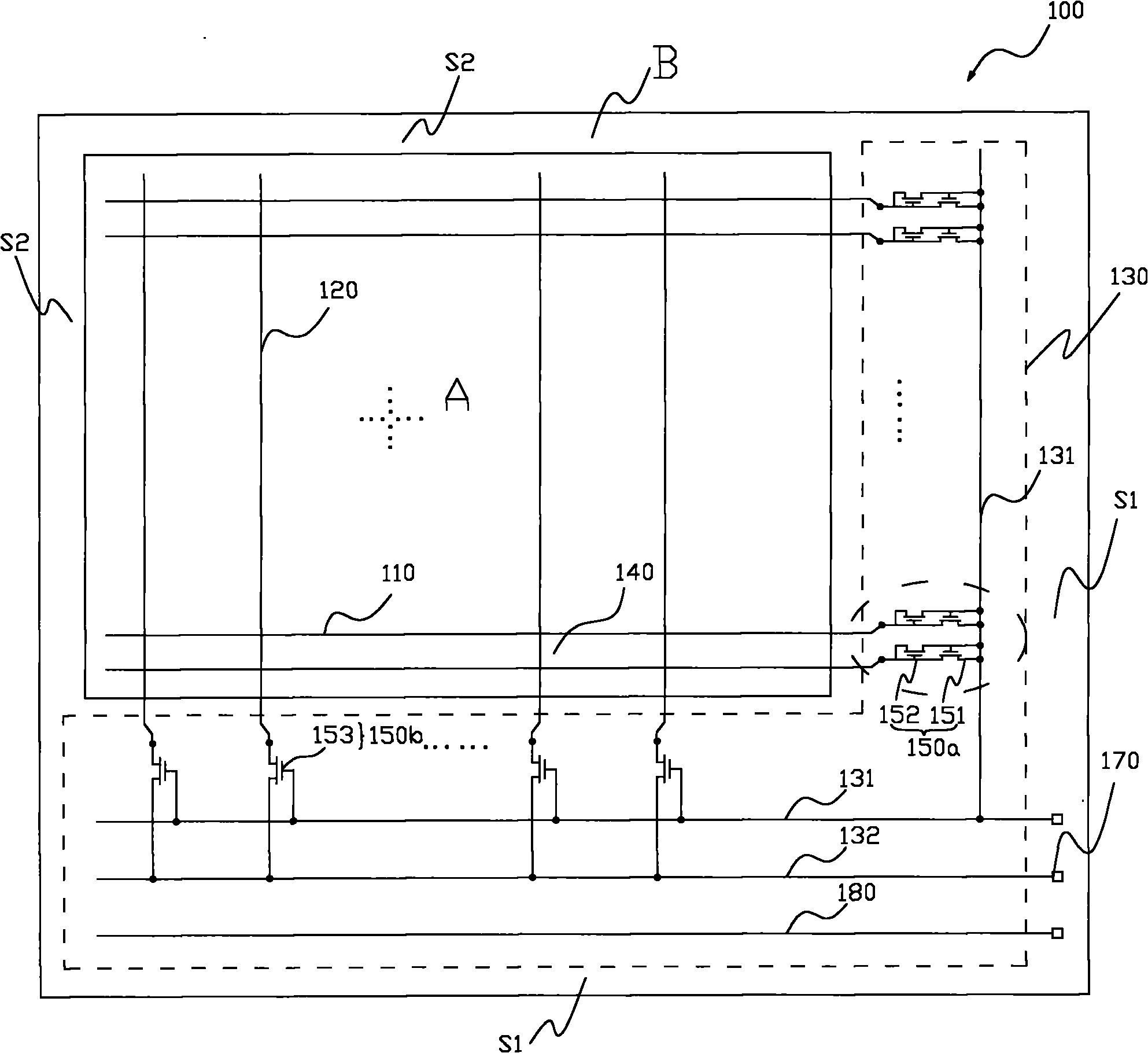

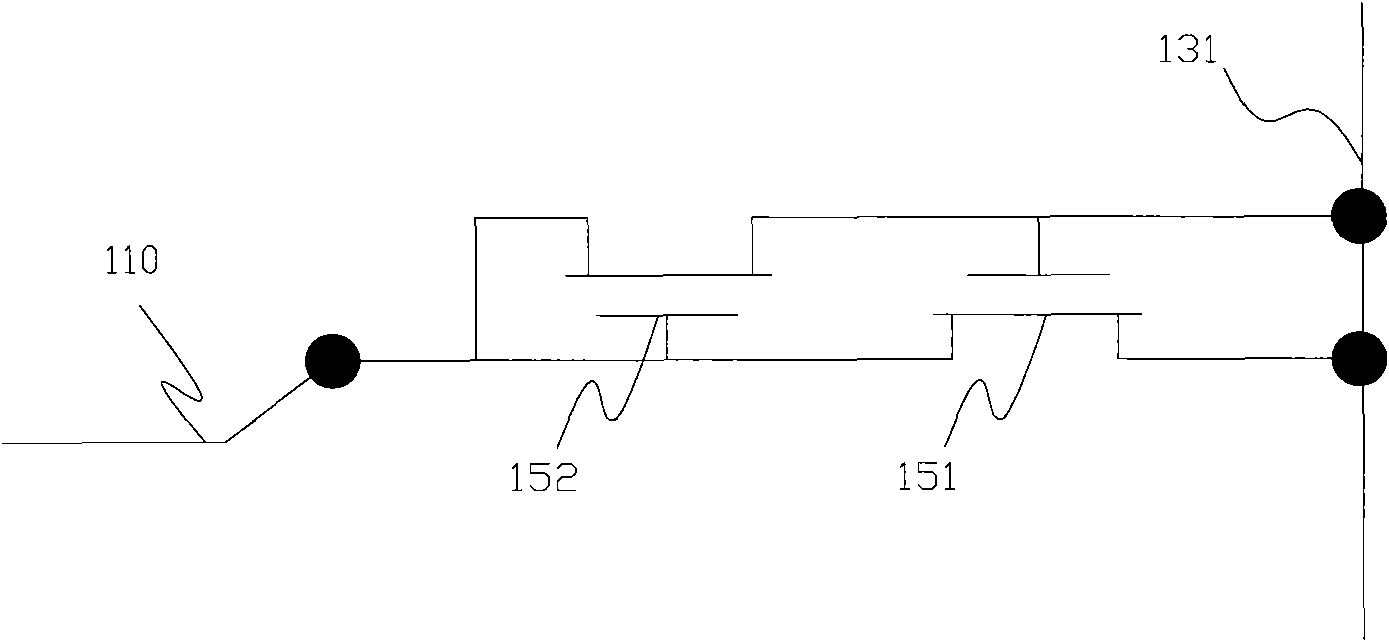

[0066] figure 2 It is a schematic diagram of the thin film transistor array substrate in this embodiment, image 3 It is a partially enlarged view of the test device in the array substrate.

[0067] like figure 2 and image 3 As shown, the thin film transistor array substrate 100 at least includes: at least two gate lines 110 and at least two data lines 120 arranged across each other on the substrate 100 , and the gate lines 110 and data lines 120 are coupled The testing device 130.

[0068] Wherein, the at least two gate lines 110 are arranged in parallel with the same spacing, and at least two data lines 120 are also arranged in parallel with the same spacing along the direction perpendicular to the gate lines 110; the gate lines 110 and data lines 120 crosses and separates an array of pixel units 140, and each pixel unit includes at least one pixel thin film transistor (not shown in the figure), the gate of the pixel thin film transistor is connected to the gate line ...

Embodiment 2

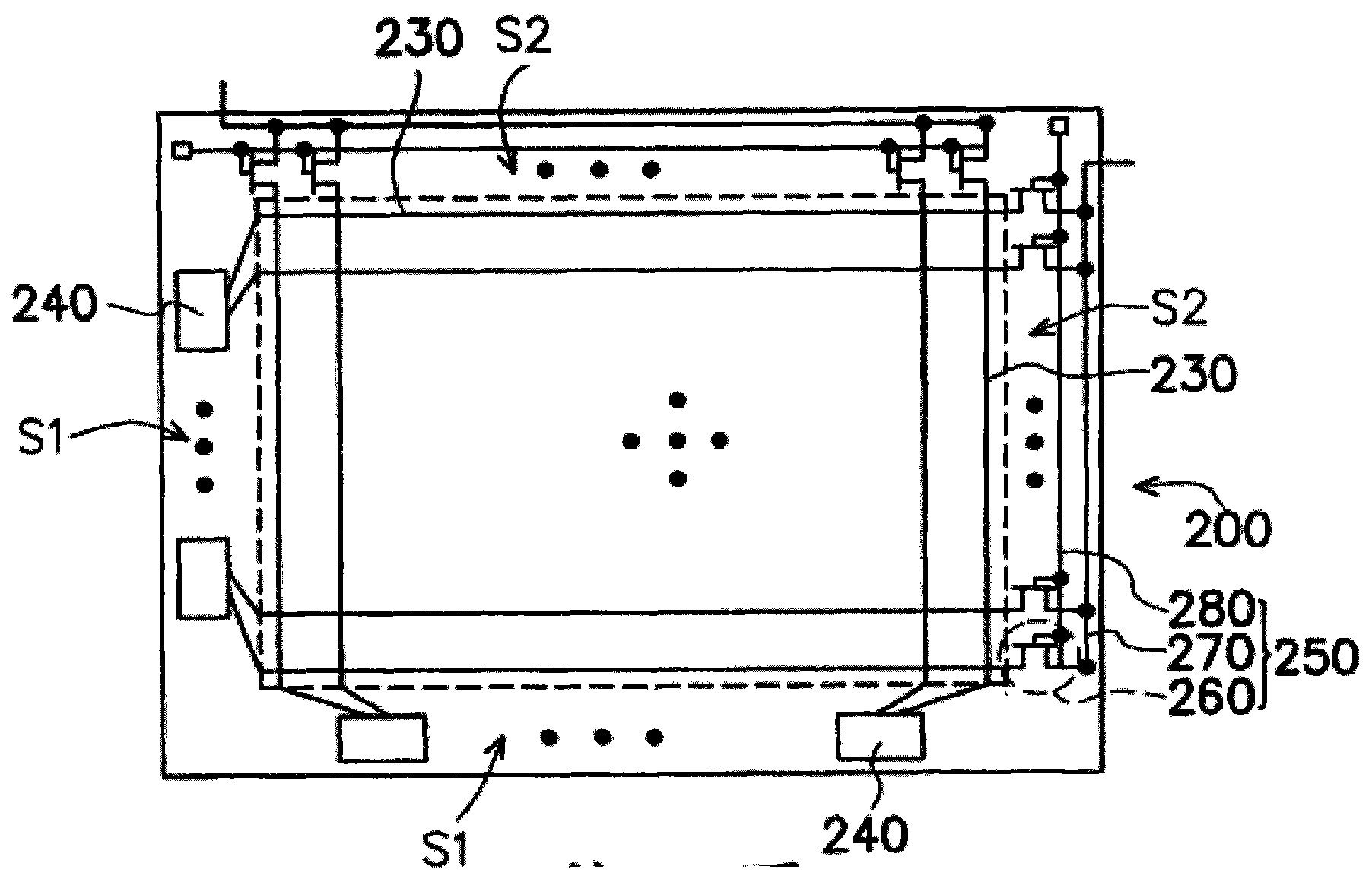

[0092] Figure 7 It is a schematic diagram of the thin film transistor array substrate in this embodiment, Figure 8 It is a partial enlarged view of the test device in the substrate.

[0093] like Figure 7 As shown, in this embodiment, the test device 330 for the thin film transistor array substrate 300 includes: a data test unit 350b, and at least two short-circuit bars 331 for gate lines and at least two short-circuit bars 332 for data lines; wherein, the data The test unit 350b includes a third thin film transistor 353 and a fourth thin film transistor 354 coupled to each other, and the data line short bar 332 and the gate line short bar 331 pass through the third thin film transistor 353 and the fourth thin film transistor 354 coupled to each other. Connect with each data line set.

[0094] Specifically, at least two gate lines 310 are divided into two gate line groups 310a, 310b. For example, counting from top to bottom, the even-numbered gate line belongs to the gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com