Deep-cone concentration machine used for acid waste water treatment in non-ferrous metal industry

A deep cone concentrator and acid waste water technology, applied in the direction of settling tank, etc., can solve the problems of inability to meet acid waste water treatment, poor flocculation effect, power consumption and other problems, and achieve low solid content, low consumption and good effect in overflow water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

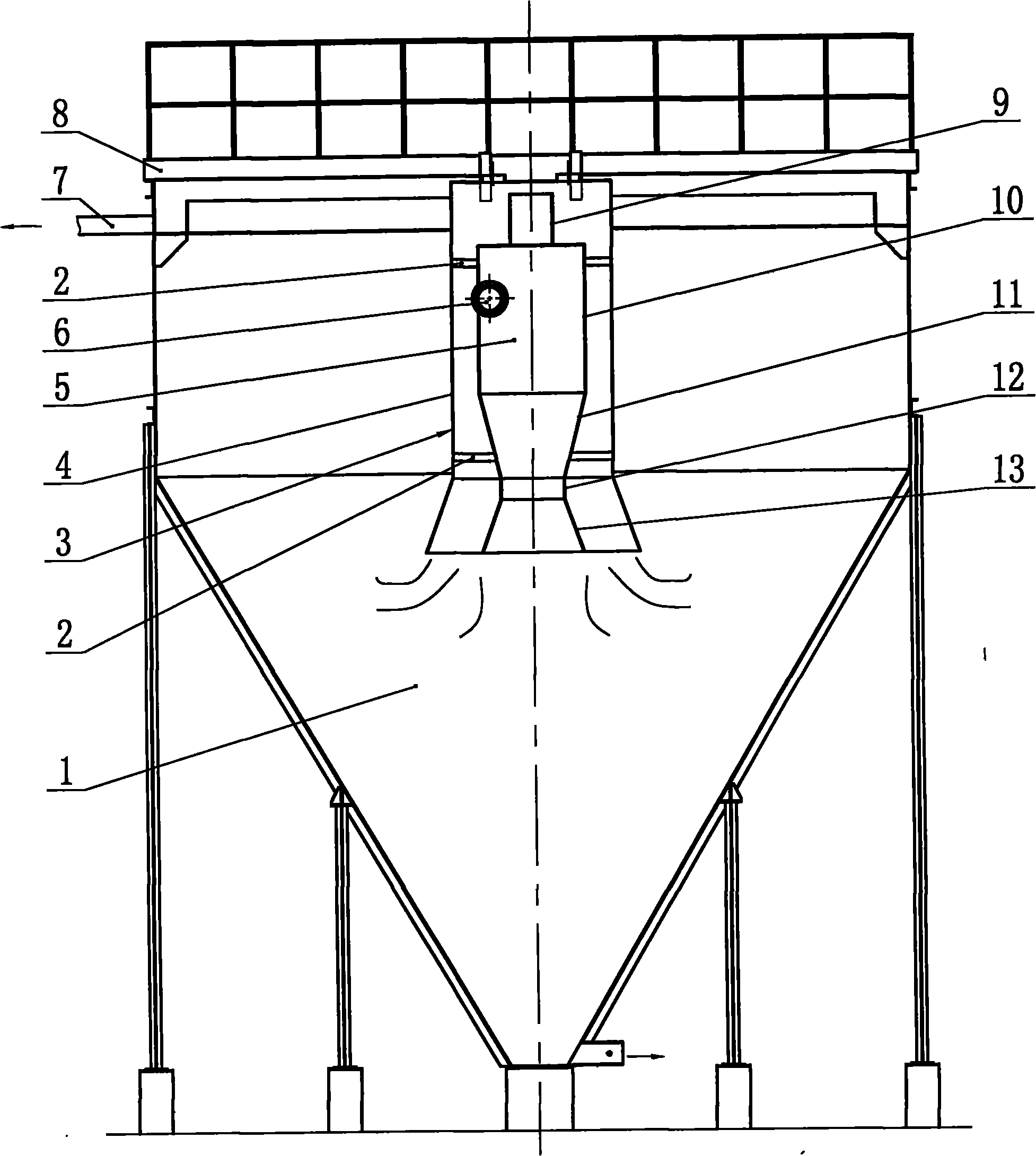

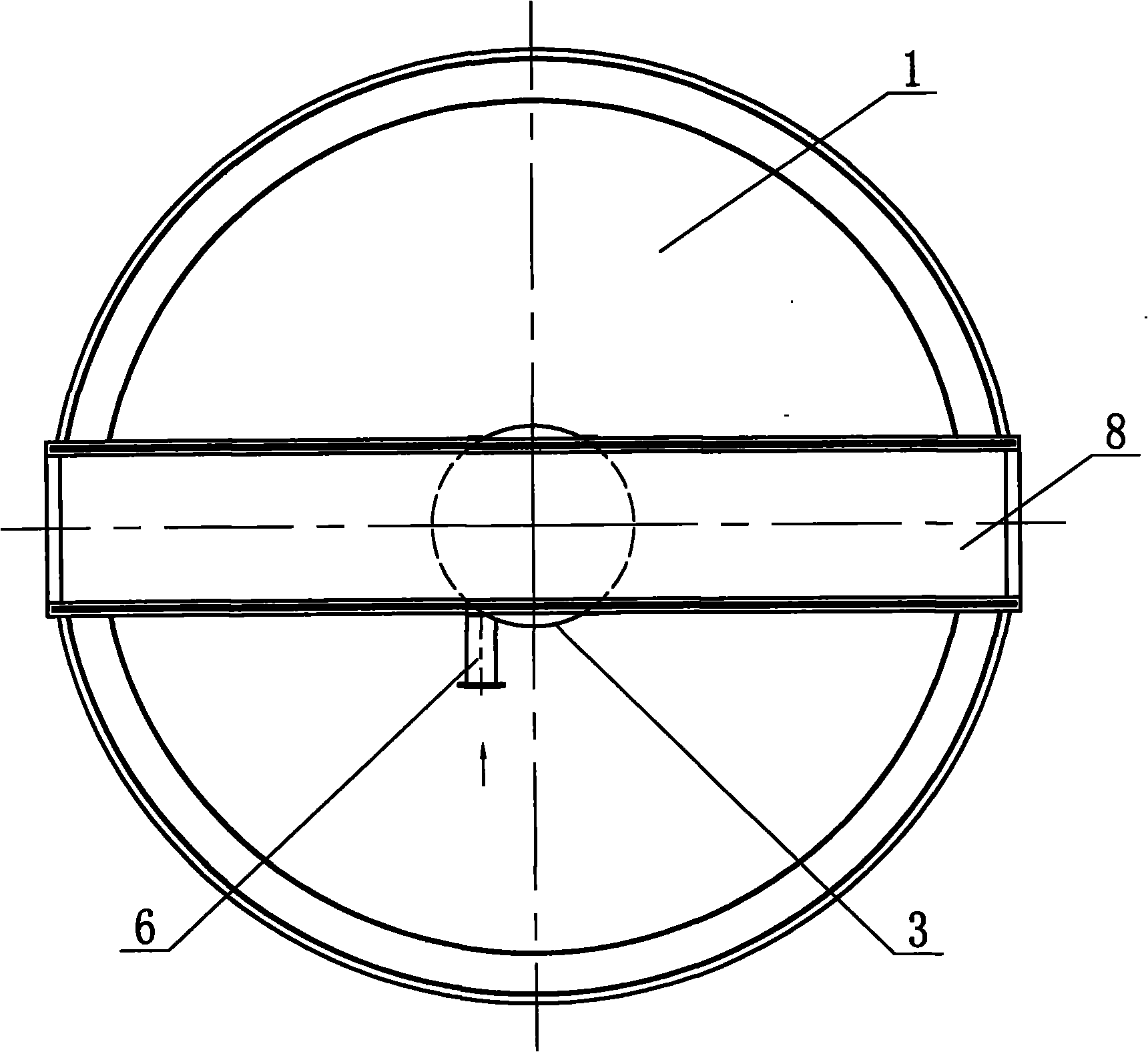

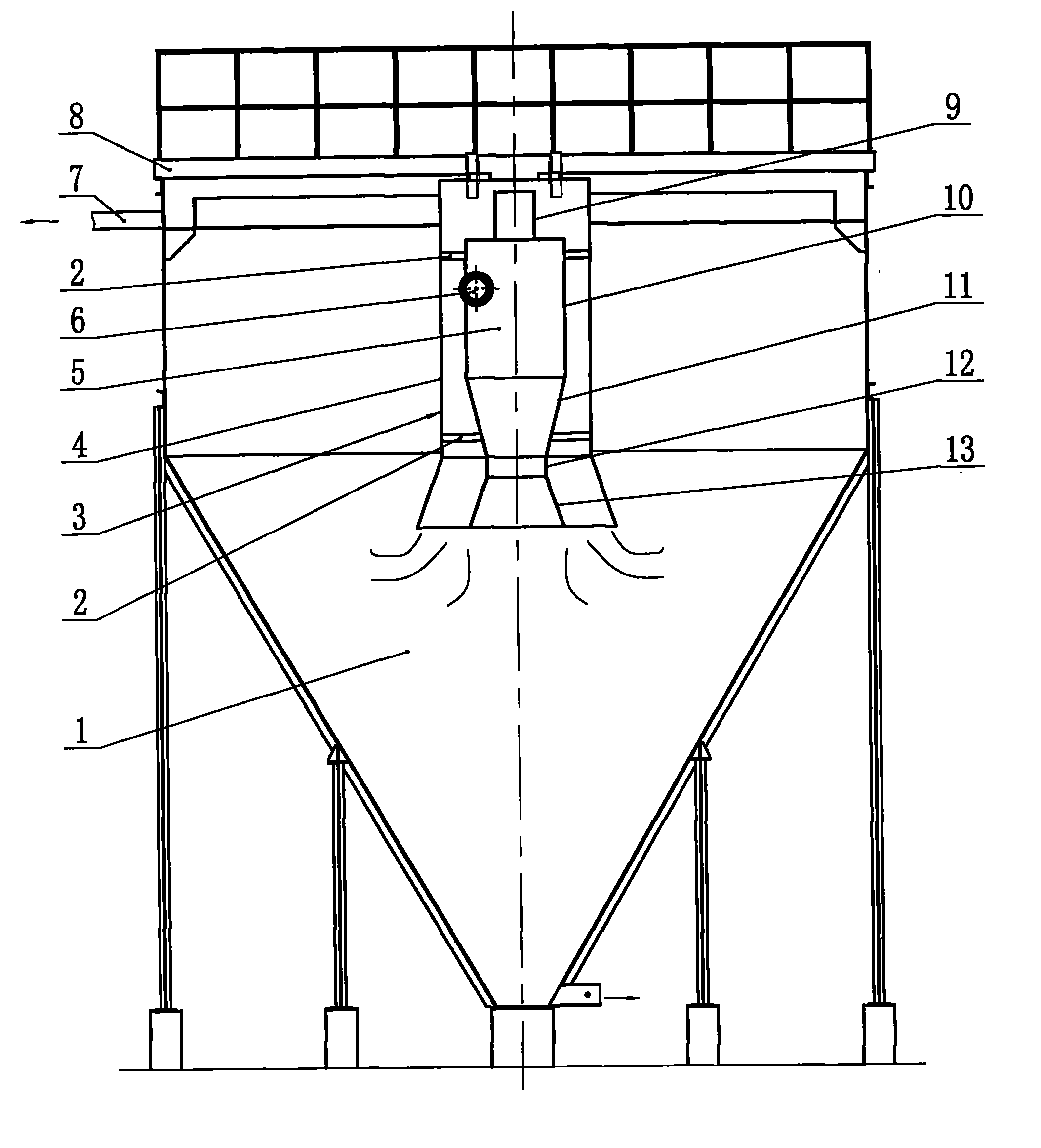

[0010] Such as figure 1 , figure 2 Shown, the present invention comprises pool body 1, bridge frame 8, distributing device 3, feed pipe 6, overflow pipe 7, and pool body 1 top is cylinder, and bottom is cone, is the container of settlement, is welded by steel plate or steel bar Made of concrete. The bridge frame 8 spans the top of the pool body 1 for pedestrians to pass through. The upper part of the distributor 3 is fixed on the bridge frame 8, and the lower end goes deep into the cone part of the pool body 1, and is used for mixing and flocculating the flocculant and waste water and distributing to the deep cone thickener. The distributor 3 has a double-layer structure with an outer cylinder 4 and an inner cylinder 5. The upper part of the outer cylinder 4 of the distributor is a cylinder, and the lower part is a cone with a small upper part and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com