Sorting method of low grade vanadium titano-magnetite

A vanadium-titanium magnetite, low-grade technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as blockage of ore bins in the crushing system, and achieve the effect of reducing the mining loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

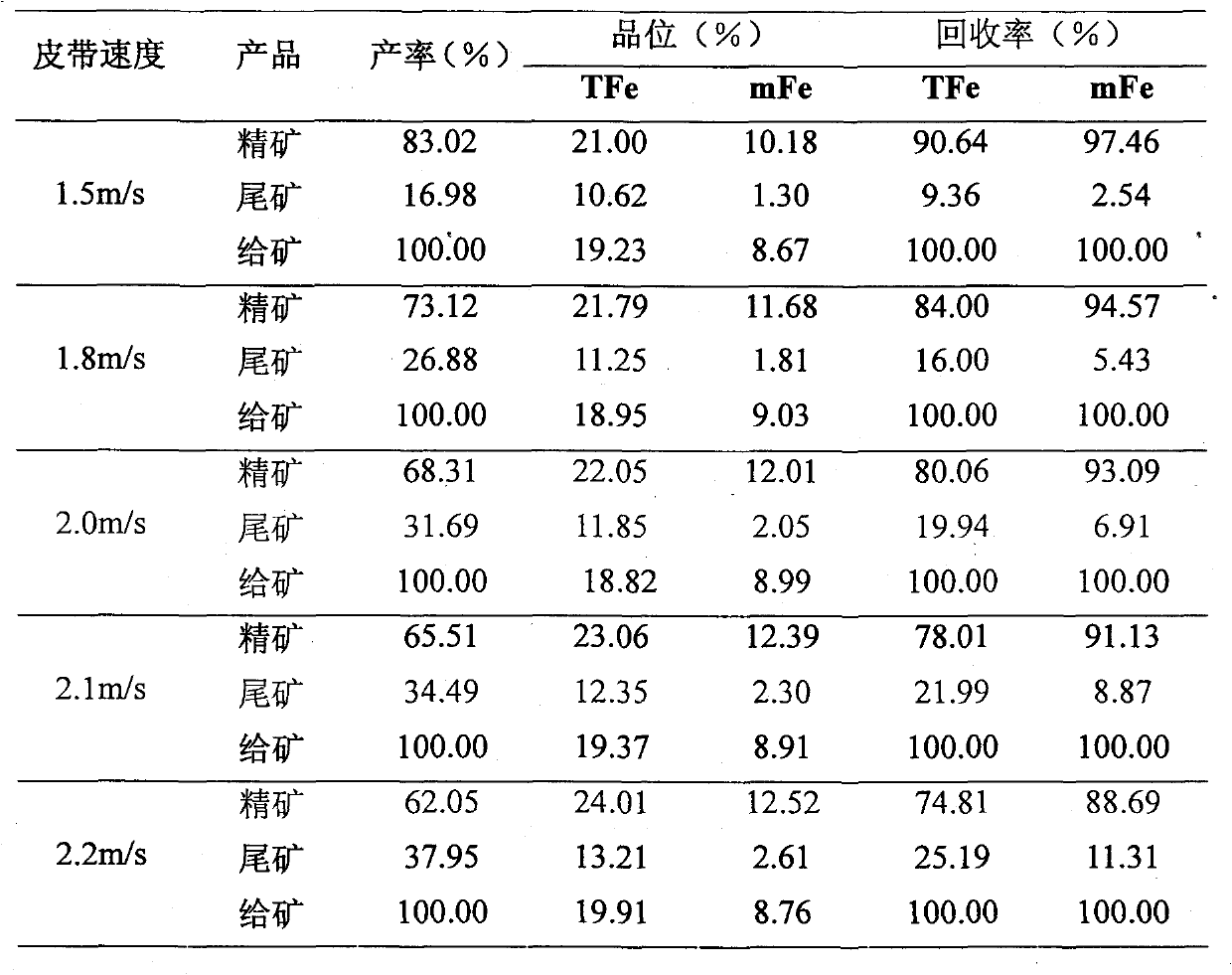

[0024] The raw ore is crushed and sieved, and the material under the sieve (below 12mm) is directly subjected to dry magnetic separation, and the belt speed and magnetic field strength tests are carried out. The test results are listed in Table 1 and Table 2.

[0025] Table 1 Result of belt speed test selected under sieve

[0026]

[0027] Table 1 shows that with the increase of belt speed, the concentrate rate decreases, the total iron (TFe) and magnetic iron (mFe) grades increase, and the recovery rate decreases. When the belt speed reaches 2.1m / s, the rate of thrown tailings has reached 34.49%, and the total iron grade of the tailings has increased by more than one percentage point compared with 1.8m / s. Therefore, it is not appropriate to continue to increase the belt speed. If the speed is too high, the total iron recovery rate of dry concentrate concentrate and the recovery rate of magnetic iron will be too low. For the recycling of waste ore, the main recovery is the...

Embodiment 2

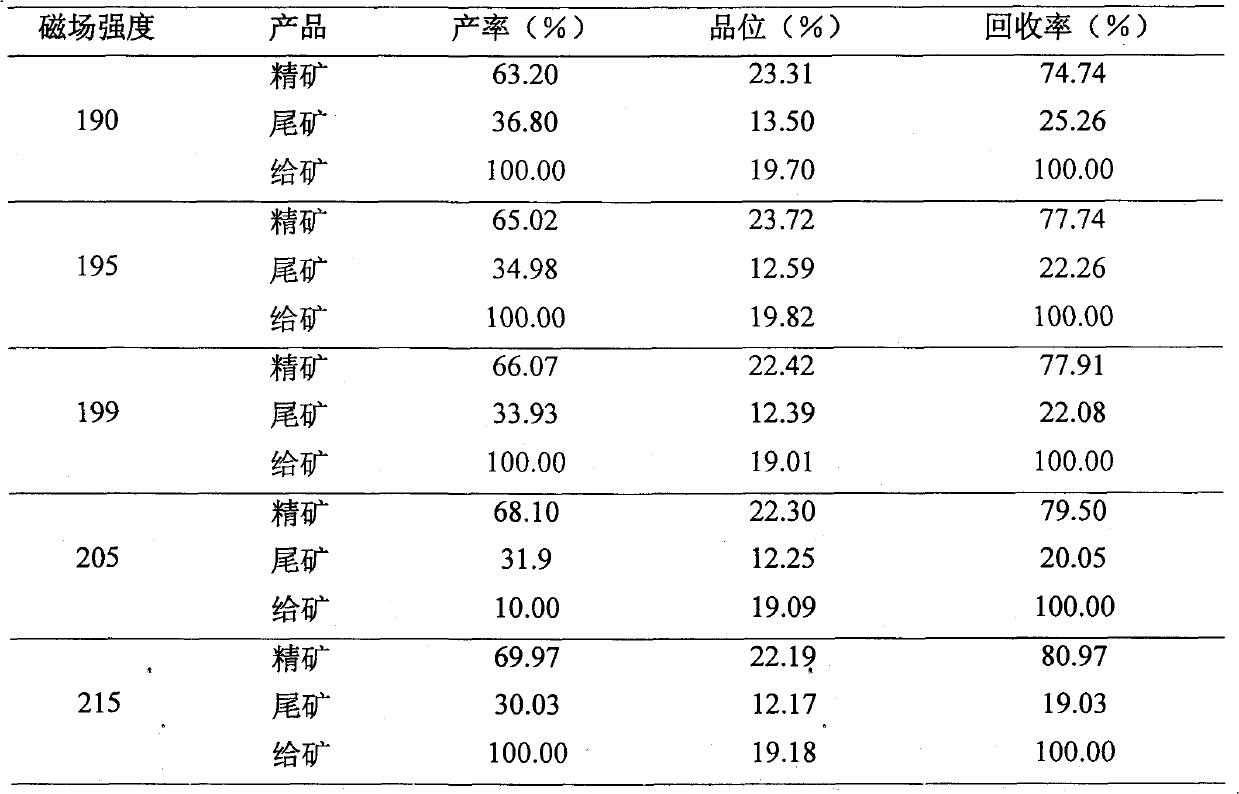

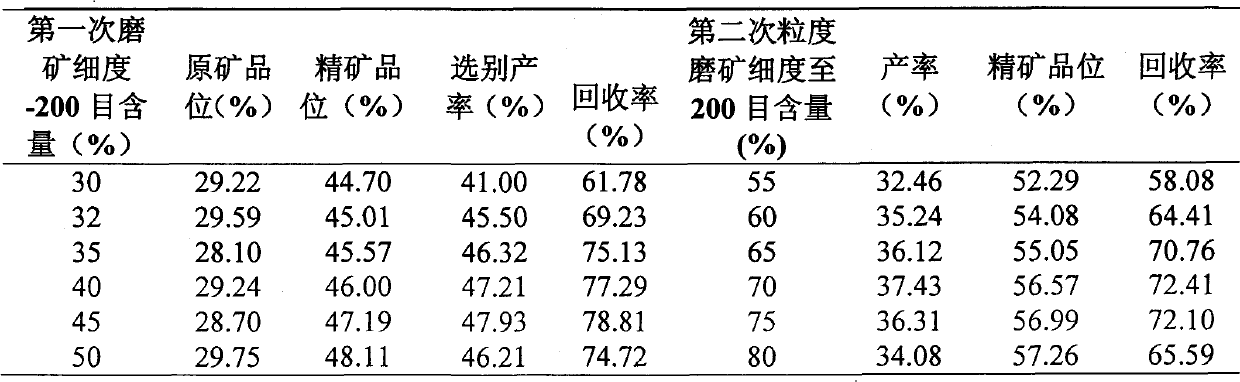

[0032] According to the conditions of the technological process of the production site, and sampling on-site, the simulation test was carried out in the laboratory, and the following results were obtained (Table 3).

[0033] Table 3. Selection index of stage grinding stage

[0034]

[0035] From the results in the above table, it can be seen that the grade and recovery rate of the first grinding increase with the increase of grinding fineness. , but the recovery rate decreases, so the optimal condition is that the fineness is 200 mesh and the content is between 35% and 45%. The relationship between the particle size and grade of the second grinding also has the same trend as the first time. With the increase of the grinding particle size, the grade also increases continuously. When the fineness is 200 mesh and the content exceeds 75%, although the grade is still in the increase, but the recovery rate is lower; so the optimal condition for the second grinding is that the fi...

Embodiment 4

[0037] 1. Using low-grade (Tfe (total iron content) <19%) vanadium-titanium magnetite as raw material, after crushing and screening; the particle size is below 12mm, and the magnetic field strength is 195-205KA / m (2400-2600OS) , After the magnetic separation equipment with a belt speed of 2.0-2.2m / s is selected, the tailings with a yield of more than 30% are thrown away, the crude iron concentrate rate is over 60%, the total iron grade is over 23%, and the total iron recovery rate is 73%. %above. The grade of the milled iron concentrate is greatly improved on the original basis, and the associated titanium minerals are enriched in the concentrate.

[0038]2. After the first grinding of the crude iron concentrate, when the fineness is 200 mesh and the content reaches 35-45%, it is sorted by a magnetic separator with a magnetic field strength of 2300OS, and the grade of vanadium-titanium-iron concentrate can be obtained: 45% or more of vanadium ilmenite concentrate, the recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com