Water-cooling die casting production process of plate blank used for medium plate

A technology of water-cooled mold casting and production process, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc. It can solve the problems of low production efficiency, shrinkage cavity, high mold consumption, etc., and achieve the effect of ensuring quality and reducing secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment.

[0018] A water-cooled die-casting production process for high-demand mold steel P80 medium-thick plate slabs. This production process uses argon protection pouring during the entire pouring process to prevent the molten steel from contacting the air after flowing out of the nozzle during the pouring process; The solid mold powder is used to protect the pouring to ensure the surface quality of the slab; the rising hole of the convection steel is adjusted to make the molten steel rise steadily in the water-cooled die casting to ensure the surface quality of the slab; the details are as follows:

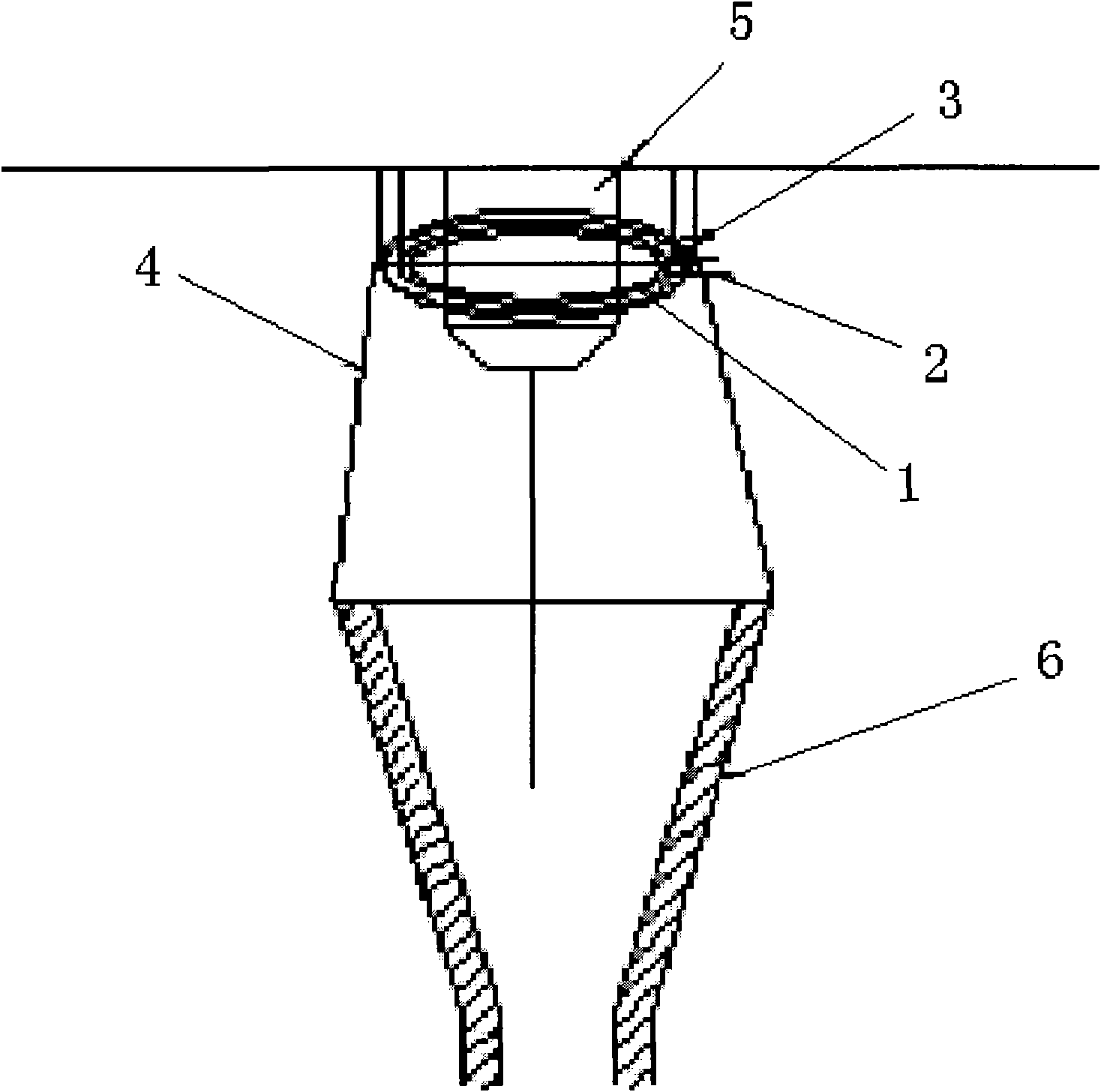

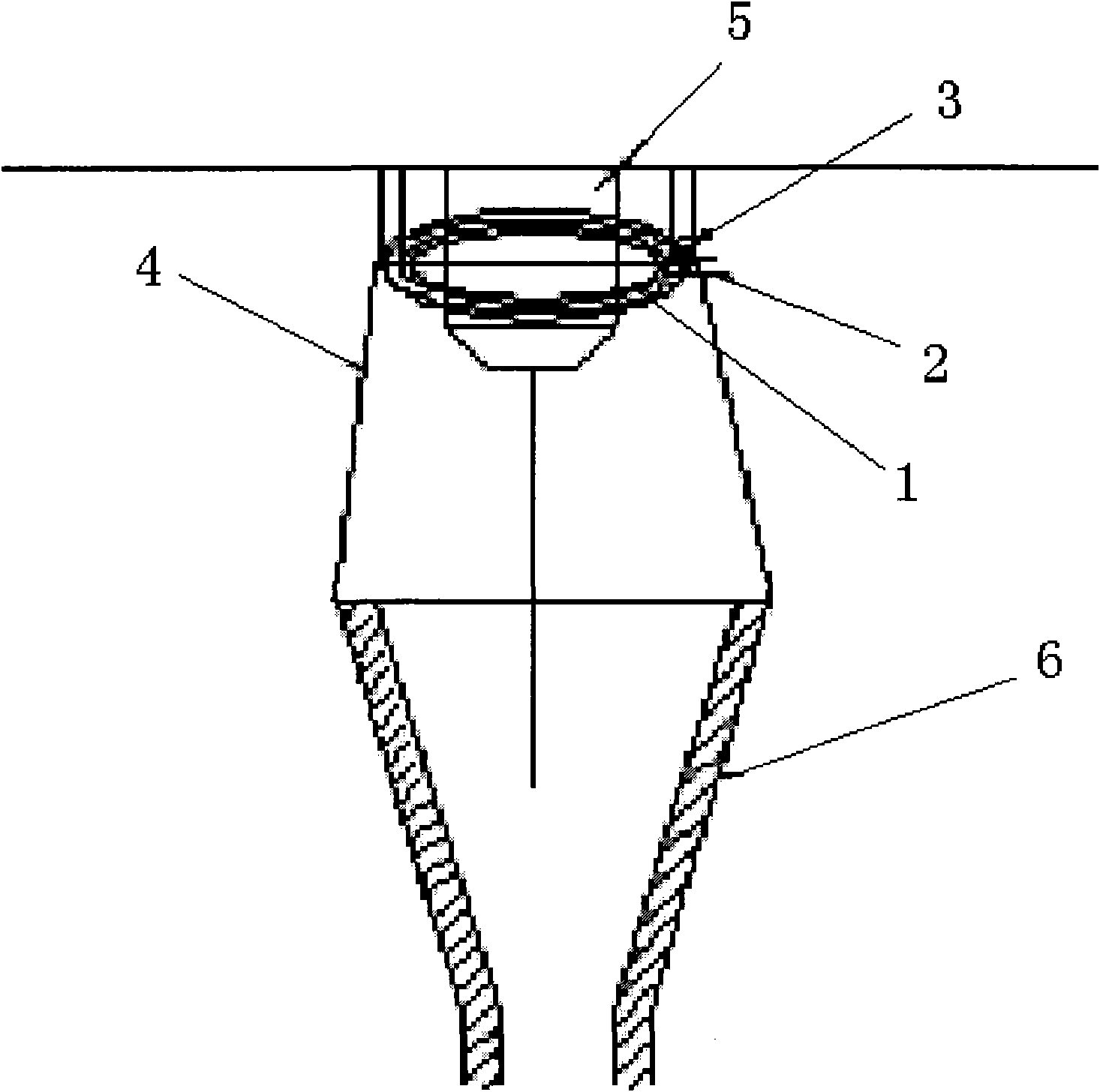

[0019] During the whole pouring process, argon protection pouring is used, figure 1 It is a schematic diagram of the argon protective casting adopted in the present invention. The pouring device consists of an argon group 1 , an argon pipeline 2 , an argon blowing double ring 3 and a sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com