Method for preparing ultrafine silver tungstate antibacterial powder by ultrasonic-homogeneous precipitation

A technology of uniform precipitation and antibacterial powder, which is applied in the direction of botany equipment and methods, chemical instruments and methods, applications, etc., and can solve the problems of large powder particles and unsatisfactory antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

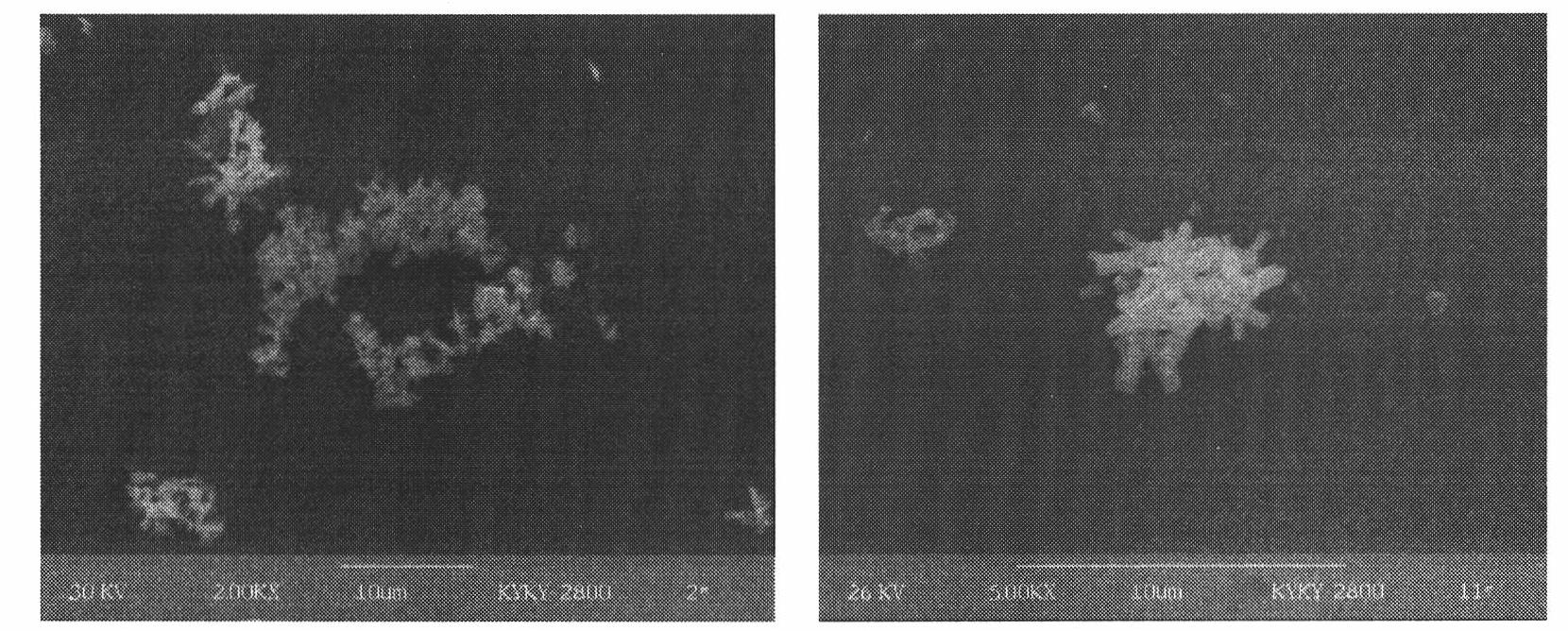

Method used

Image

Examples

Embodiment 1

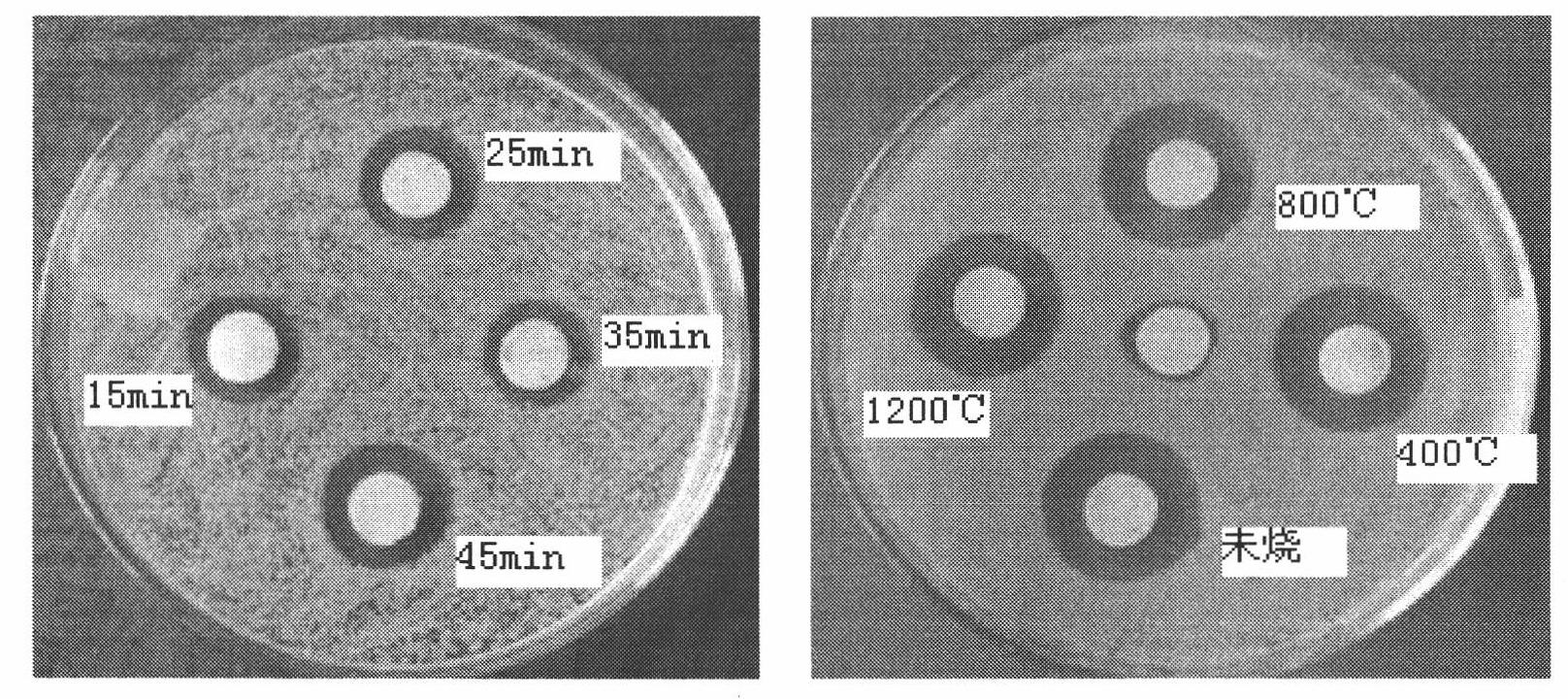

[0026] Slowly add 10mL of sodium acetate aqueous solution with a concentration of 3.20mol / L to the stirred silver nitrate aqueous solution at a rate of 0.01mL / s, and react for 15min to 45min under ultrasonic heating at 20°C to 40°C with stirring, and then filter , fully washed with deionized water to remove nitrates. A precipitate of silver acetate was obtained.

Embodiment 2

[0028] Add 5.0 g of sodium tungstate into 50 mL of deionized water at a temperature of 20°C to 40°C, and stir to obtain an aqueous solution of sodium tungstate. Then the sodium tungstate aqueous solution is slowly added dropwise to the stirred silver acetate aqueous solution at a rate of 0.005mL / s, and reacted for 15min to 45min under ultrasonic heating at 20°C to 40°C with stirring, then filtered and fully washed with deionized water , to remove acetate. Dry to obtain silver tungstate powder.

Embodiment 3

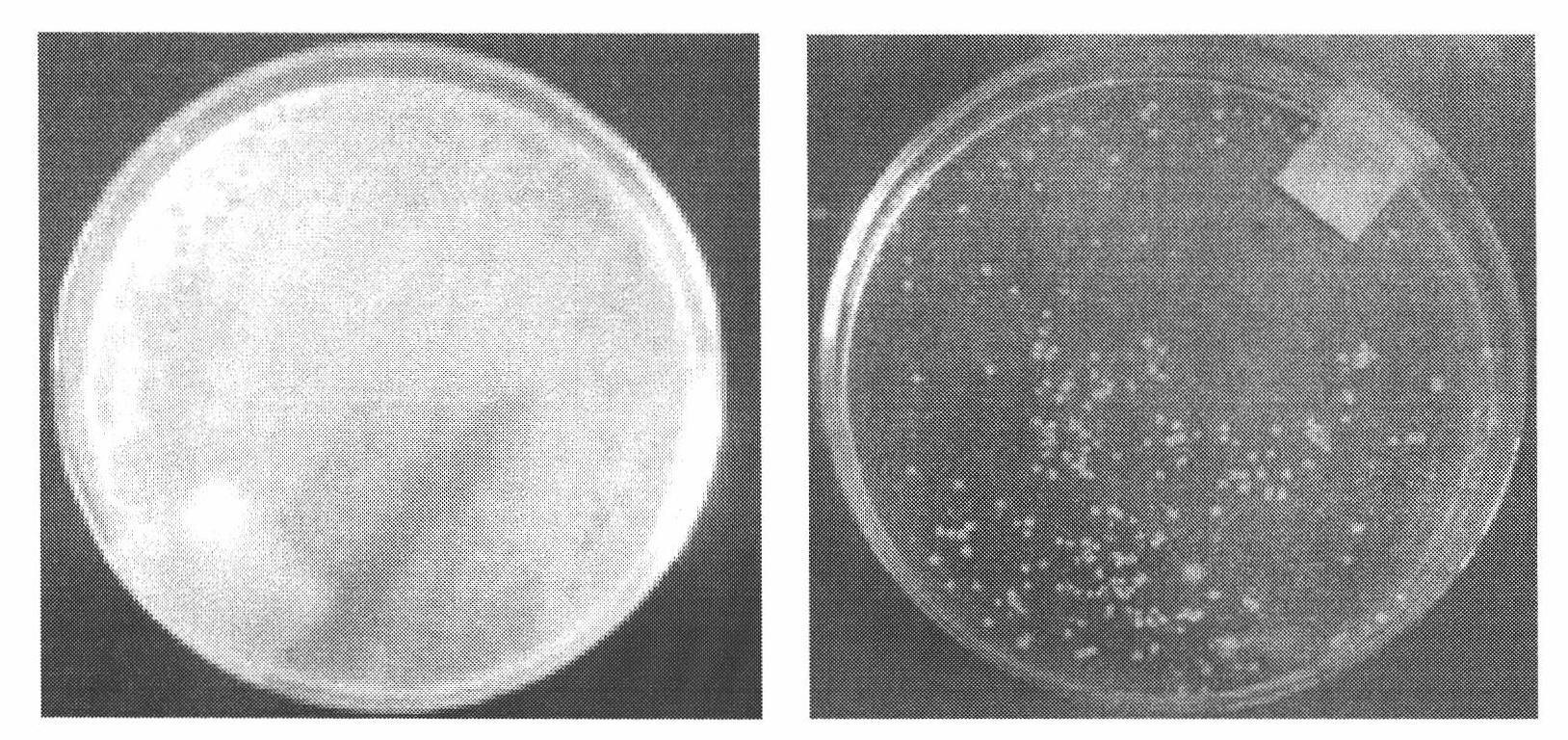

[0030] The antibacterial powder is applied to the sanitary enamel at 1.5wt%-3.0wt% of the total weight of the dry glaze, and finally antibacterial ceramics are obtained. The antibacterial effect is tested by dipping culture method. The antibacterial rate is above 90%, and the appearance of the antibacterial ceramics is no Discoloration and distortion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com