Multiplex pulse laser integrated system

An integrated system, multi-channel pulse technology, applied in optics, optical components, instruments, etc., can solve problems such as loss of beam energy, and achieve the effect of sufficient pulse energy, high energy stability, and no loss of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

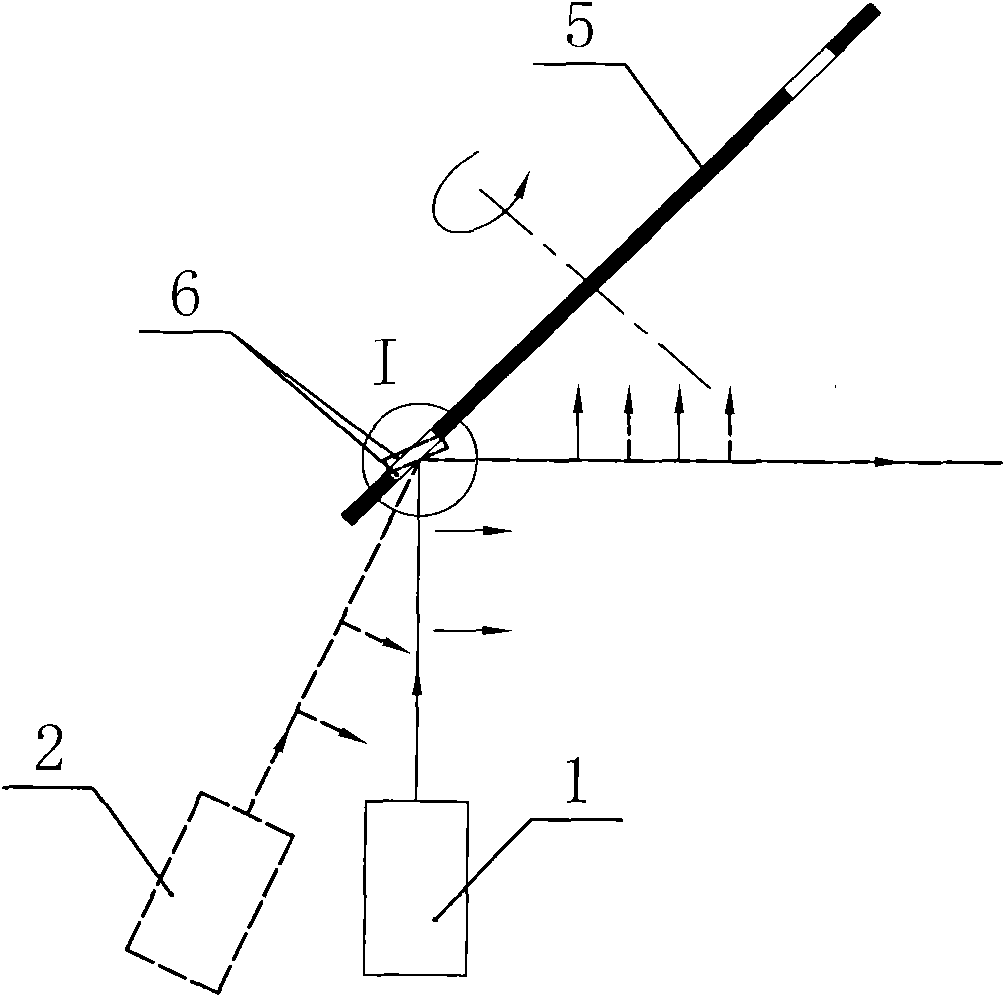

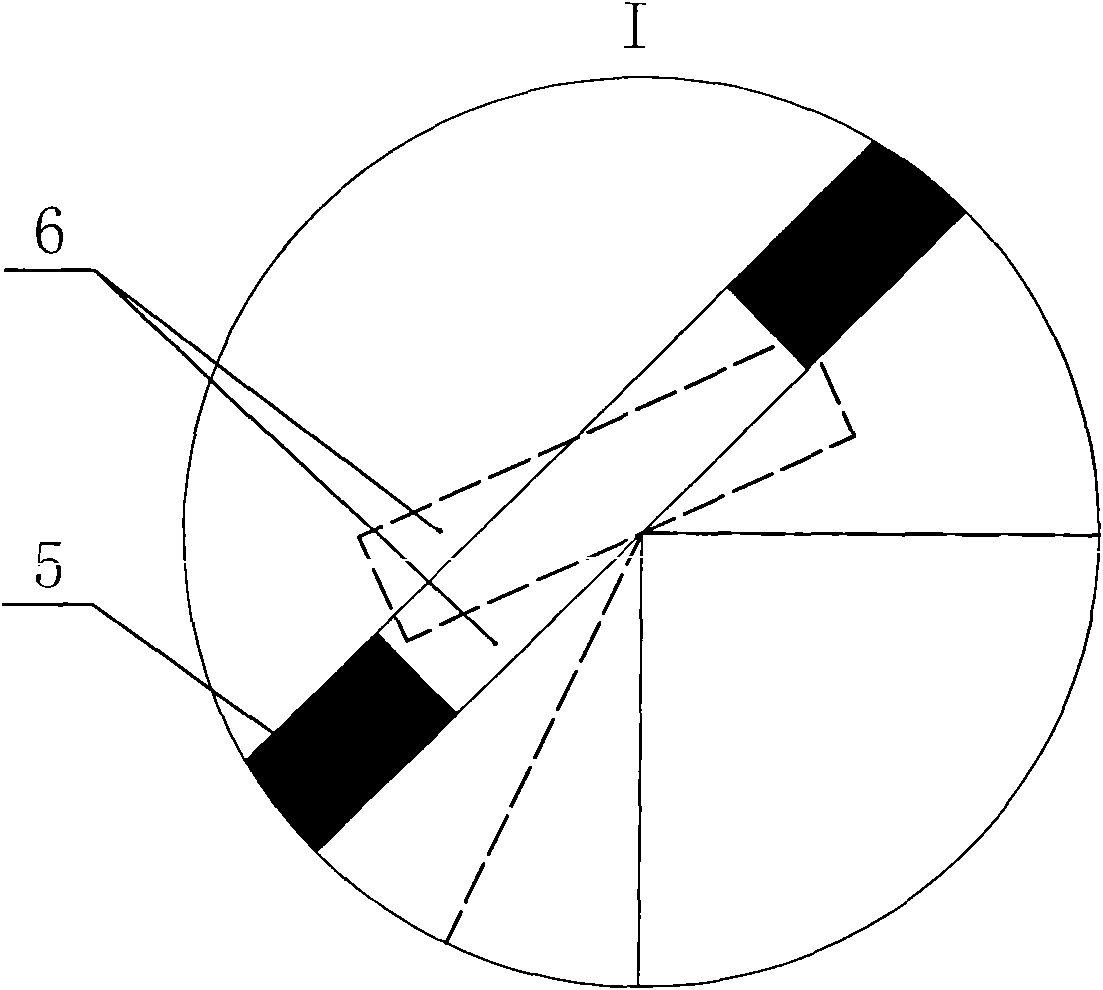

[0014] Specific embodiment 1: the synthesizing mechanism of multi-channel pulsed laser integration system adopts reflector group, the number of reflector 3 in the reflector group is the same as the number of laser sources, and the light beams that each laser source sends aim at the same point that is intersection point 4, The angles of each reflector 3 correspond to the laser source one by one, so that when the reflector driving device drives the reflector 3 to pass through the intersection point 4 of the laser source one by one, the light emitted by the laser source is in the same state after being reflected by the corresponding reflector 3. On one optical path, the mirror driving device (not shown in the figure) drives the mirror group to circulate through the intersection point 4 one by one under the control of the synchronizer (not shown in the figure), and the mirror group is at least one group, or Multiple groups pass through the junction 4 repeatedly, and the synchronize...

specific Embodiment 2

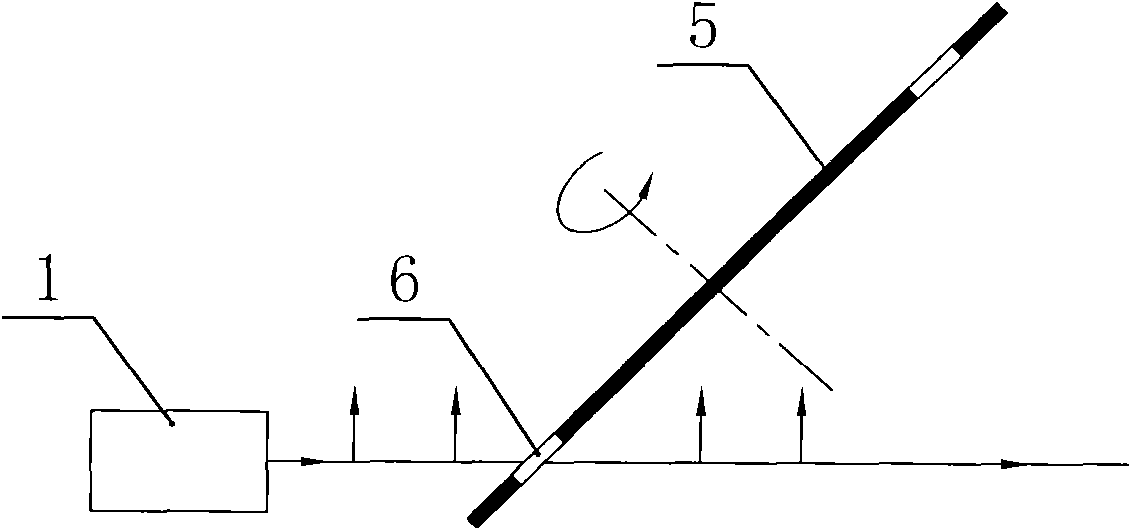

[0015] Specific embodiment 2: this specific embodiment can also take the following mode: each group of reflecting mirror groups includes a light transmission hole 6, each group of light transmission holes 6 plus the number of reflection mirrors 3 is the same as the number of laser sources, and the mounting frame 5 is composed of The mirror driving device is driven to rotate around the central axis. The first laser source 1 in the plurality of laser sources is arranged on the rear side of the mounting frame 5, and the remaining laser sources are arranged on the other side of the mounting frame 5. All laser sources emit The intersection point 4 of the light beam falls on the trajectory of the mirror group rotation, and the light beams sent by the other laser sources except the first laser source 1 overlap with the light beams sent by the first laser source 1 after being reflected by the corresponding reflector 3, so that This avoids the problem that all reflectors 3 need to be ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com