High oxidation resistance medium/long chain fat emulsion injection and preparation method thereof

A long-chain fat emulsion and oxidative technology, which is applied in the field of pharmacy, can solve the problems of reducing the effect of emulsion lipid oxidation, the enlargement of emulsion particles, and the dosage not meeting the safety requirements, so as to reduce the degree of oxidation and reduce potential hazards , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

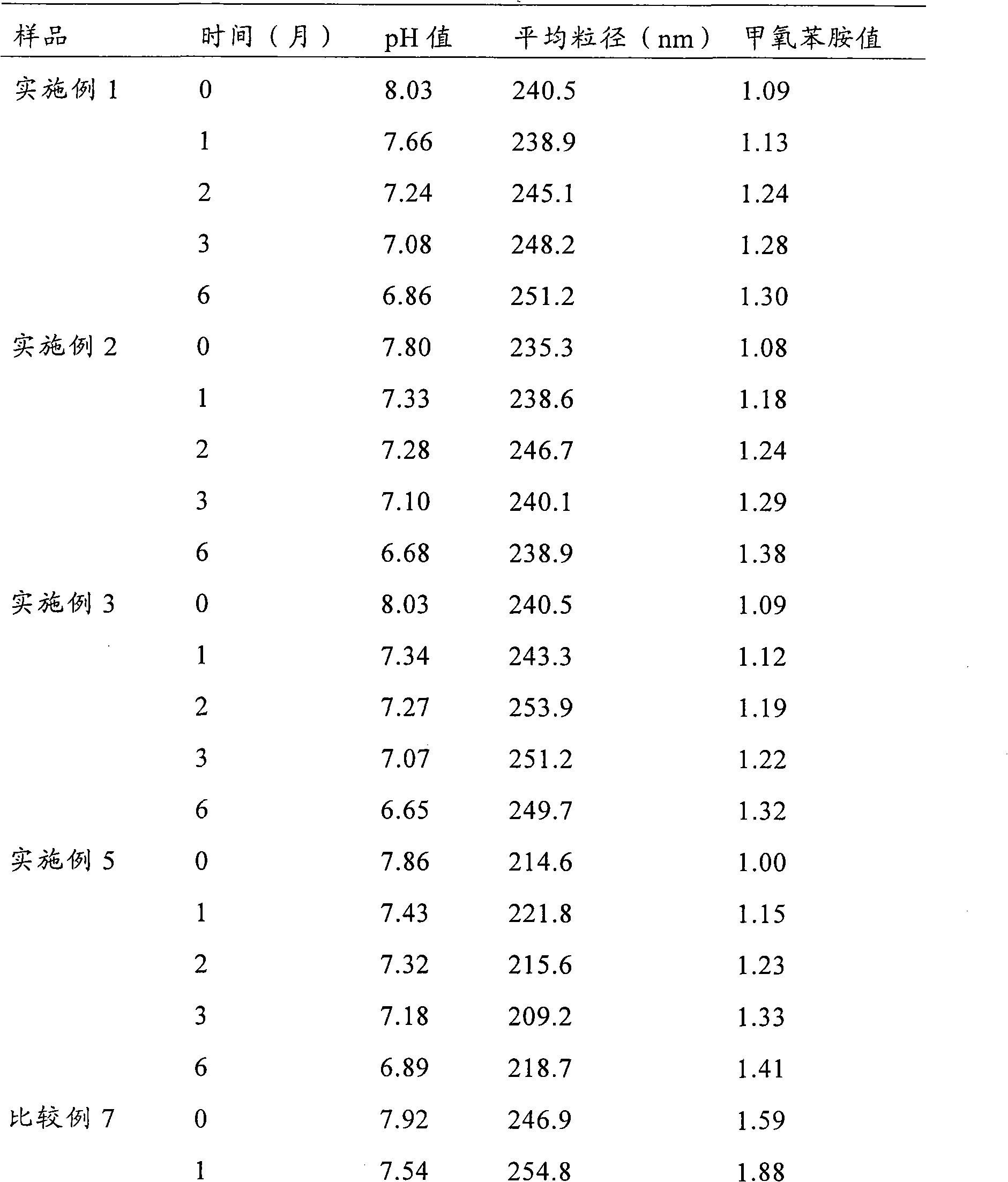

Embodiment 1

[0039] Under nitrogen protection, weigh 100g of soybean oil for injection, 100g of medium-chain triglyceride, heat to 60°C, add 12g of egg yolk lecithin under high-speed stirring, stir well as the oil phase, and add edetate calcium sodium 0.05 g. Add 25 g of glycerin for injection into 600 ml of water for injection, mix well and filter with a 0.45 μm filter membrane as the water phase. Add the oil phase to the water phase under high-speed stirring to make colostrum, adjust the pH value to 9.0-10.0 with NaOH, add water for injection to 1000ml, and repeatedly homogenize through a high-pressure homogenizer to check the size of the milk particles. The diameter is less than 1 μm. After the emulsion is filtered, it is filled with nitrogen, plugged, capped, sterilized in a rotary steam sterilizer, and cooled to obtain the high antioxidant fat emulsion injection of soybean oil and medium-chain triglyceride.

Embodiment 2

[0041] Under nitrogen protection, weigh 100g of soybean oil for injection, 100g of medium-chain triglycerides, and 0.2g of oleic acid, heat to 60°C, add 12g of egg yolk lecithin under high-speed stirring, and stir evenly as the oil phase. Add 0.1 g of disodium diacetate and 25 g of glycerin for injection into 600 ml of water for injection, mix well, and filter with a 0.45 μm filter membrane as the water phase. Add the oil phase to the water phase under high-speed stirring to make colostrum, adjust the pH value to 9.0-10.0 with NaOH, add water for injection to 1000ml, and repeatedly homogenize through a high-pressure homogenizer to check the size of the milk particles. The diameter is less than 1 μm. After the emulsion is filtered, it is filled with nitrogen, plugged, capped, sterilized in a rotary steam sterilizer, and cooled to obtain the high antioxidant fat emulsion injection of soybean oil and medium-chain triglyceride.

Embodiment 3

[0043] Under nitrogen protection, weigh 100g of soybean oil for injection and 100g of medium-chain triglycerides, heat to 60°C, add 12g of egg yolk lecithin under high-speed stirring, and stir evenly as the oil phase. Add calcium sodium edetate 0.005 g. Add 0.05 g of sodium oleate and 25 g of glycerin for injection into 600 ml of water for injection, mix well and filter with a 0.45 μm filter membrane as the water phase. Add the oil phase to the water phase under high-speed stirring to make colostrum, adjust the pH value to 9.0-10.0 with NaOH, add water for injection to 1000ml, and repeatedly homogenize through a high-pressure homogenizer to check the size of the milk particles. The diameter is less than 1 μm. After the emulsion is filtered, it is filled with nitrogen, plugged, capped, sterilized in a rotary steam sterilizer, and cooled to obtain the high antioxidant fat emulsion injection of soybean oil and medium-chain triglyceride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com