Comprehensive utilization method of industrial furnace gas

An industrial furnace and pretreatment technology, applied in the field of metallurgy, can solve problems such as increasing carbon consumption, energy consumption for heating, and increasing energy consumption for operation, so as to achieve the effect of reducing carbon usage, reducing energy consumption, and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes but does not limit the present invention through the description of specific embodiments of the present invention.

[0021] The method of the present invention is aimed at mainly containing CO 2 The industrial furnace gas or tail gas is treated to reduce CO 2 Emissions, effective use of waste heat and carbon resources in furnace gas, and reduction of energy consumption.

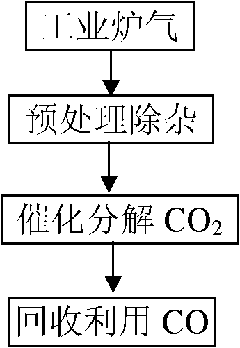

[0022] Specifically, the comprehensive utilization method of industrial furnace gas provided by the invention comprises the following steps (see figure 1 ):

[0023] A. Pretreatment and removal of impurities for industrial furnace gas;

[0024] B. In a temperature environment not exceeding 1450°C, use a catalyst to reduce the CO in the industrial furnace gas treated in step A 2 Decomposed into CO;

[0025] C. Using the CO obtained in step B.

[0026] The decomposed CO can be recycled and used in processes that require CO to participate in the reaction, and the waste heat o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com