Multichannel collecting and correcting device of alignment signal of photoetching machine

A multi-channel acquisition and calibration device technology, which is applied in the field of multi-channel acquisition and calibration devices for alignment signals of lithography machines, can solve problems such as differences between SS signals and set values, inconsistencies in signal acquisition channels, etc., to eliminate influence and save software The effect of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, preferred embodiments according to the present invention will be further described with reference to the accompanying drawings.

[0020] figure 2 A schematic diagram of the alignment signal generation process is shown. It should be pointed out that in order to improve the signal-to-noise ratio in the process of signal transmission, detection and conversion, the amplitude of the laser signal is usually modulated by an optical signal modulator. refer to figure 2 , the modulated illumination beam is irradiated onto the alignment mark, and the periodic light spot stripes 305 are generated by the imaging module. During the alignment scanning process, the periodic light spot stripes 305 sweep across the reference grating 306 at a constant speed along with the movement of the workpiece table, and are transmitted to the photoelectric sensor through the detection optical fiber 307 to obtain a light intensity signal curve 308 .

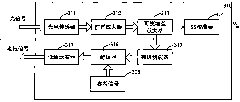

[0021] image 3 A schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com