Method for preparing three-component phononic crystal by using scattering objects

A phononic crystal and three-component technology, which is applied in the field of preparing three-component phononic crystals by using scatterers, can solve the problems that the preparation method of three-component phononic crystals has not been reported, and achieve rapid development, stable performance, Highly designable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method for preparing three-component phononic crystals by using scatterers of the present invention is to arrange and evenly wrap the scatterers in a matrix. The matrix is epoxy resin with different proportions and epoxy resin with different proportions. Resin refers to 2206A and 2206B. When epoxy resin 2206A and epoxy resin 2206B are used as casting materials, they have the characteristics of suitable operating time, low viscosity and good fluidity. When epoxy resin 2206A and epoxy resin 2206B are used as curing The material has the characteristics of low density and large modulus.

[0029] The wrapping process is realized by the forming mold, the structure of the forming mold is as follows:

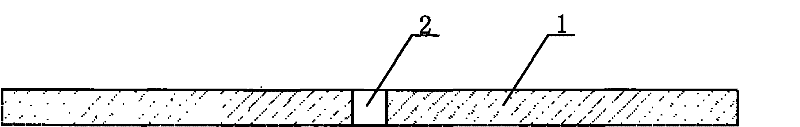

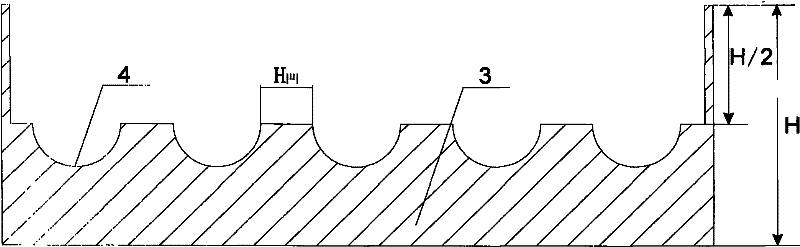

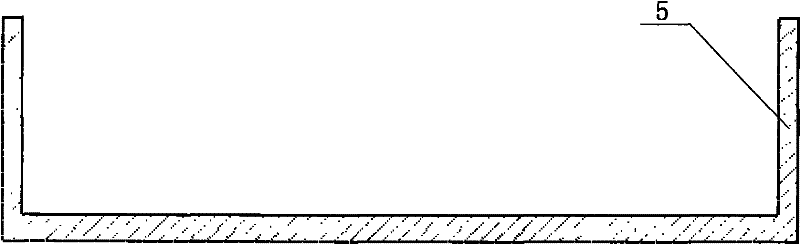

[0030] Combine Figure 1-3 , The base forming mold is composed of an upper forming plate 1, a lower forming plate a3 and a lower forming plate b5. The upper forming plate has a square structure with a basic external size of C×K×h (length×width×thickness), and a casting hole 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com