Preparation method of polyfluortetraethylene medium-pressure casing pipe for current transformer

A technology of polytetrafluoroethylene and current transformer, which is applied in the field of electric power, can solve the problems of high processing cost, inconvenient maintenance and transportation, and fragile and fragile materials, and achieve the reduction of mold manufacturing cost, light specific gravity and high dielectric constant. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

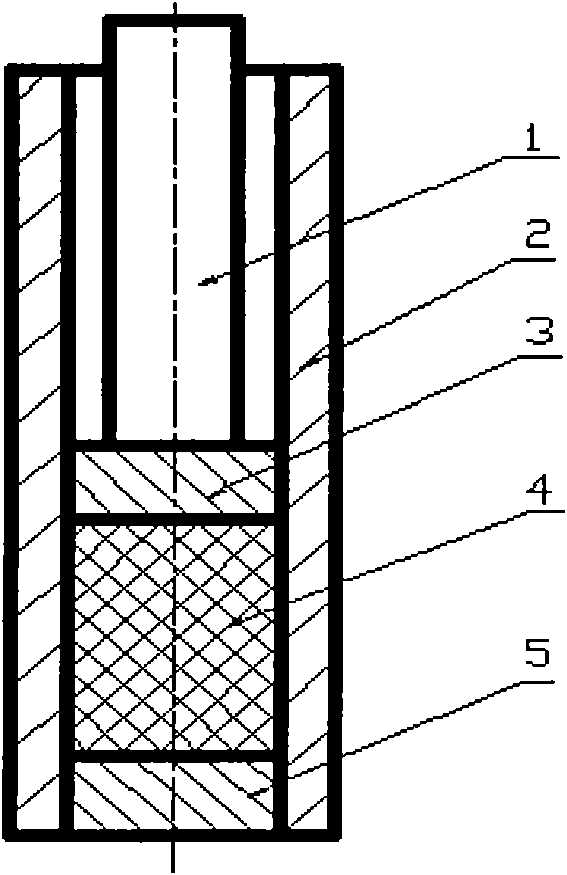

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

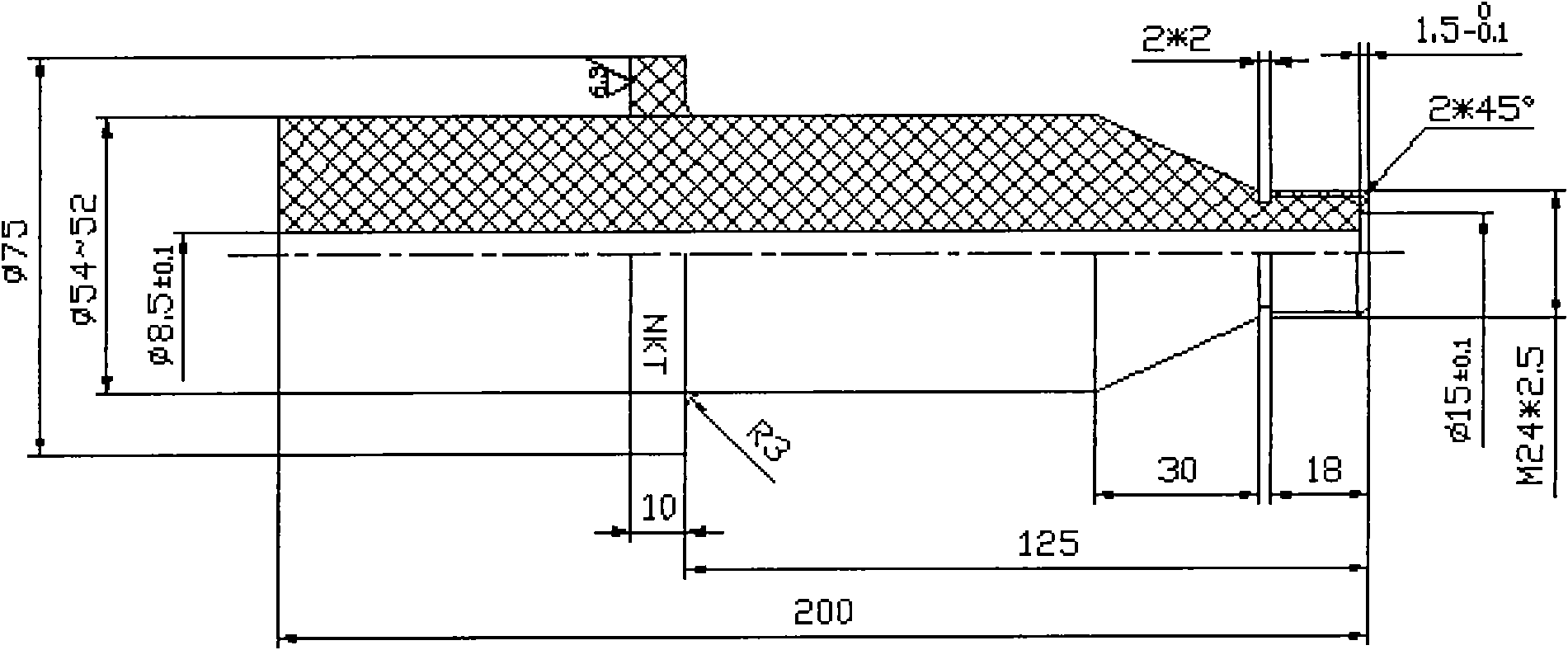

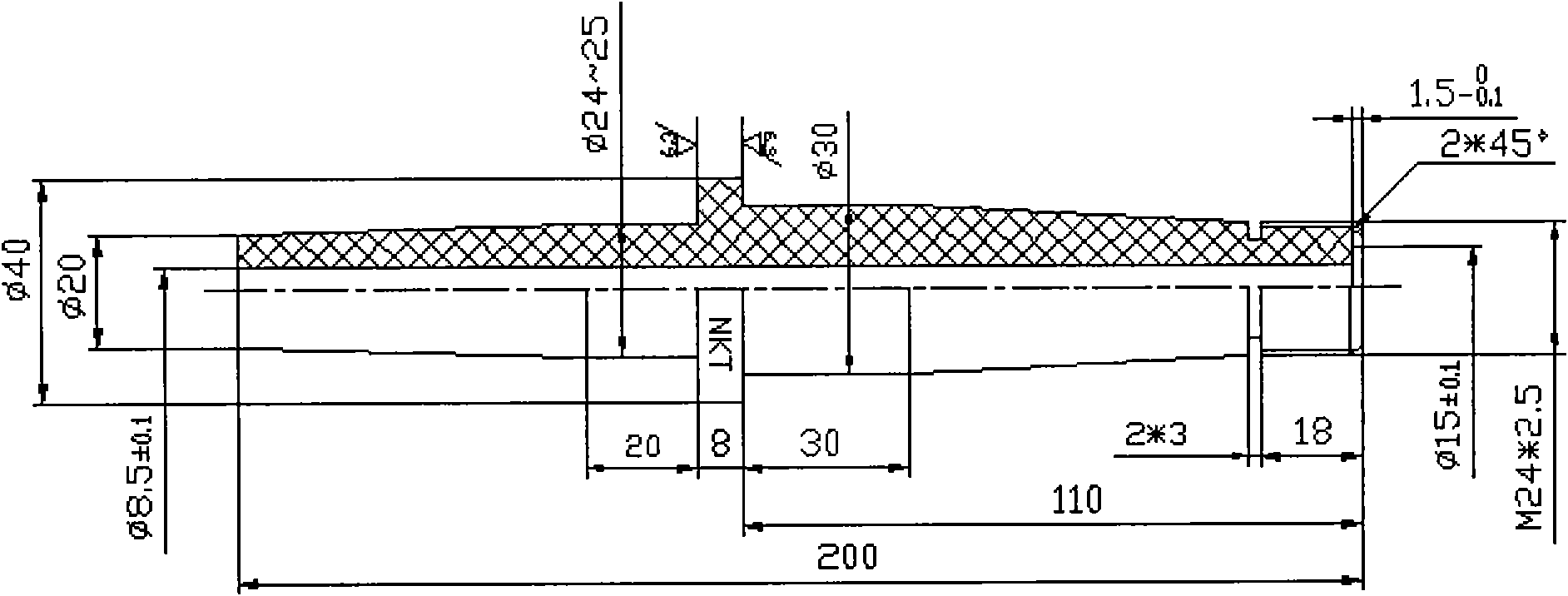

[0025] make figure 1 , 2 The method of the two specifications of the current transformer PTFE medium-voltage bushing (insulated terminal) shown is as follows.

[0026] 1. Raw material sampling.

[0027] Suspended polytetrafluoroethylene F4 particle diameter: 150-300μm, apparent density 0.6g / l.

[0028] 2. Mold design and selection

[0029] A mold with a reasonable structure is an important condition to ensure the excellent performance and accurate size of the molded product. The design of the mold should be compatible with the molding process, and have the characteristics of maximum production capacity, safe operation, simple manufacture, low cost and durable use.

[0030] ①. Design process parameters

[0031] After the PTFE molded preform is sintered and cooled, the axial and radial dimensions will shrink or increase. The shrinkage rate is related to factors su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com