In-containing lead-free solder for on-vehicle electronic circuit

A technology of lead-free solder and on-board electronics, which is applied to the assembly of printed circuits, printed circuits, and printed circuit manufacturing of electrical components. It can solve the problems of not showing heat cycle resistance, etc., and achieve excellent heat cycle resistance, stability and reliability. , the effect of suppressing the deterioration of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

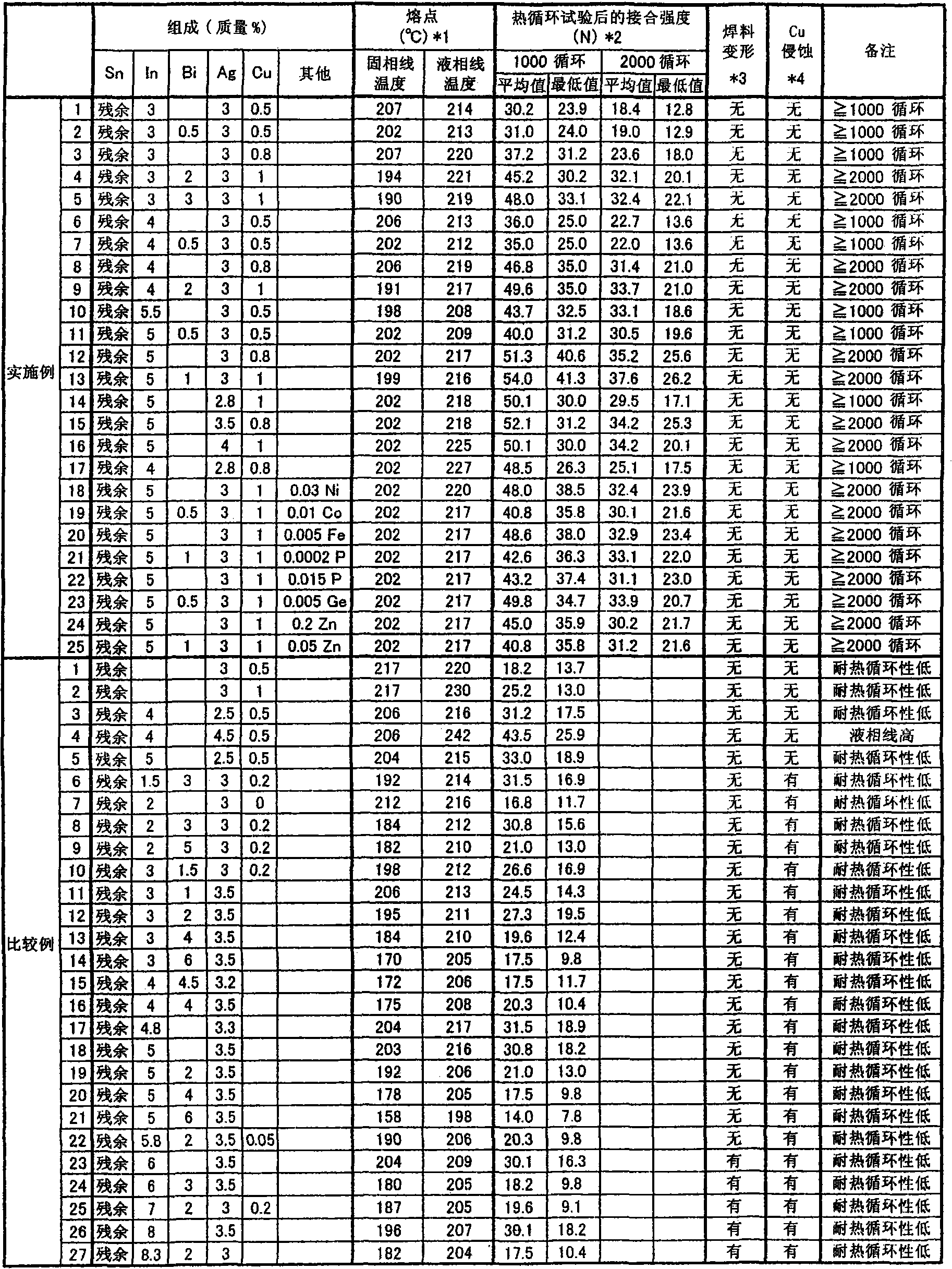

[0081] In this example, solder alloys having the respective compositions shown in Table 1 were prepared, and their properties were evaluated in the following manner.

[0082] Table 1 shows the compositions of the lead-free solders of Examples and Comparative Examples in the present invention.

[0083] [Table 1]

[0084] [Table 1]

[0085]

[0086] In this example, melting point measurement, heat cycle test, deformation test, and Cu corrosion test were performed for each solder alloy. The points of each test are as follows.

[0087] Melting point determination ( * 1):

[0088] The solidus temperature and liquidus temperature were measured by differential scanning calorimetry (DSC). The heating rate of the differential scanning calorimetry device was 5° C. / min, and the sample weight was 15 g.

[0089] In consideration of thermal influence on electronic components or printed circuit boards during soldering, the liquidus temperature is preferably 230° C. or lower. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com