UV-curable coating composition for automotive parts

A composition and curing technology, applied in the direction of coating, etc., can solve the problems of not providing the physical properties of the coating film, plastic material damage, productivity reduction, etc., and achieve the effect of excellent material adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be described in more detail.

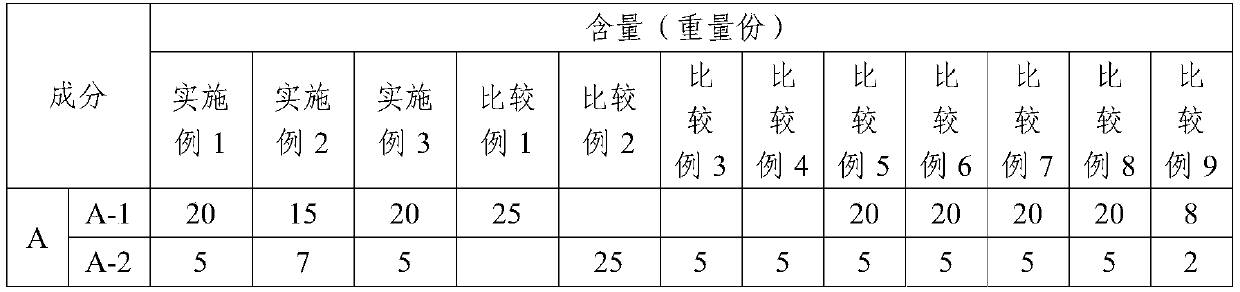

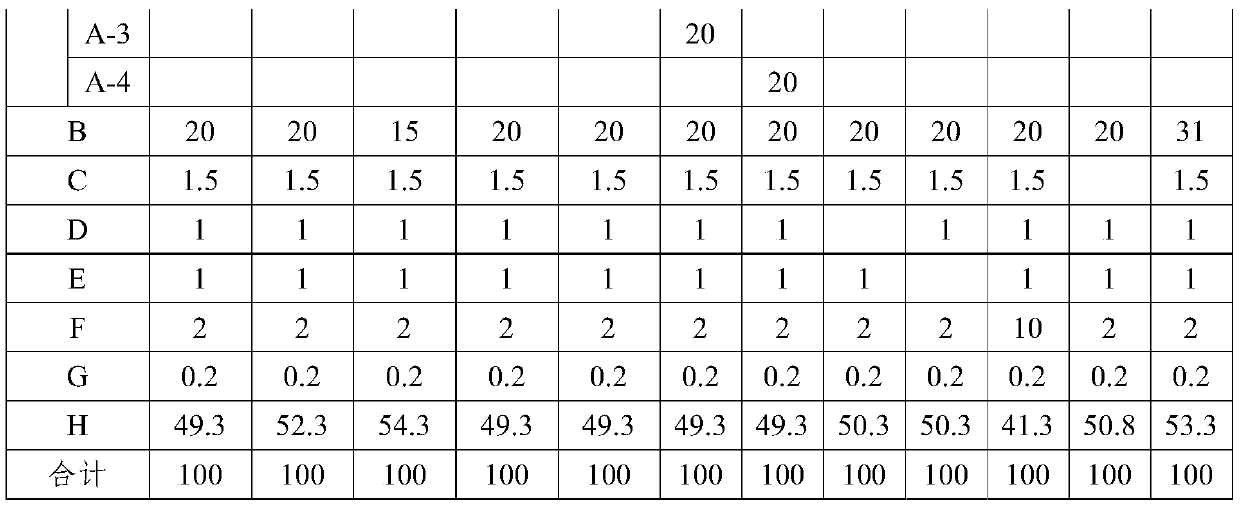

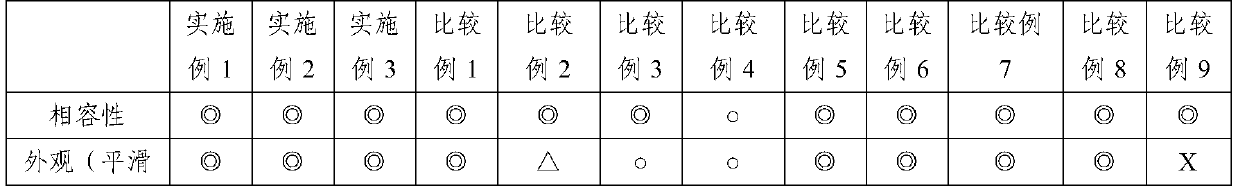

[0015] The ultraviolet curable coating composition of the present invention is characterized in that it contains 25 to 75% by weight of a polyfunctional urethane acrylate having two or more functional groups based on the total 100% by weight of the composition excluding the solvent. Polymer; 20-55% by weight of acrylate monomer; 0.5-6% by weight of resin dispersed with nano silicon dioxide; 0.5-5% by weight of adhesion enhancer; 0.5-5% by weight of sagging control agent and 1 to 10% by weight of a photopolymerization initiator, wherein the polyfunctional urethane acrylate oligomer having two or more functional groups is a urethane acrylate oligomer having two or more polymerizable functional groups a polymer; and a mixture of urethane acrylate oligomers having 5 or more polymerizable functional groups.

[0016] The coating composition of the present invention reduces mold defects of molded products ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com