Ceramic circuit board, method for manufacturing ceramic circuit board, and module using ceramic circuit board

A technology for circuit substrates and ceramic substrates, applied in circuits, printed circuits, electrical components, etc., can solve the problems of weak solder layer and reduced thermal cycle characteristics, and achieve the effect of excellent thermal cycle characteristics and good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

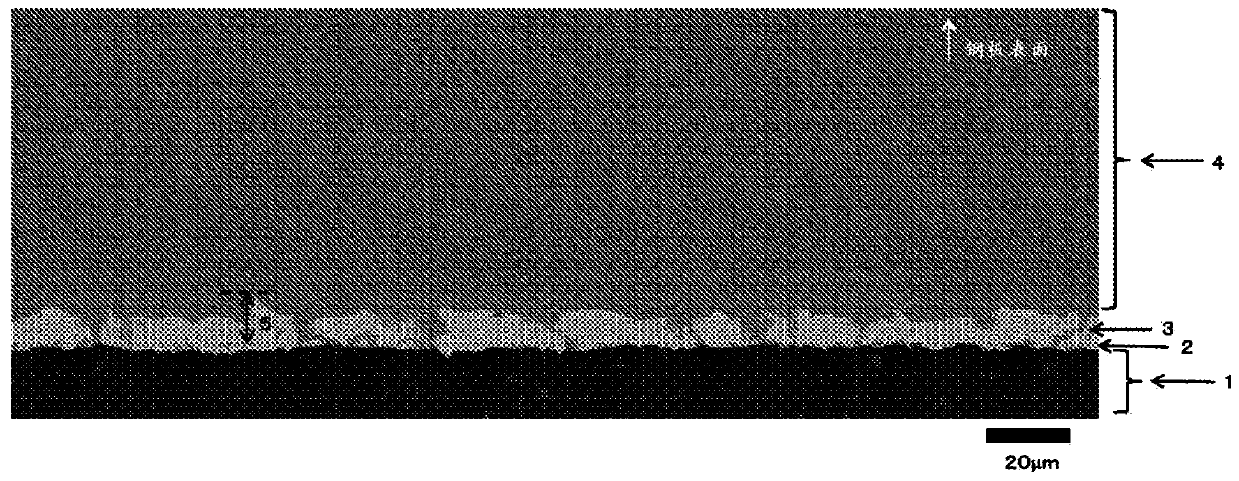

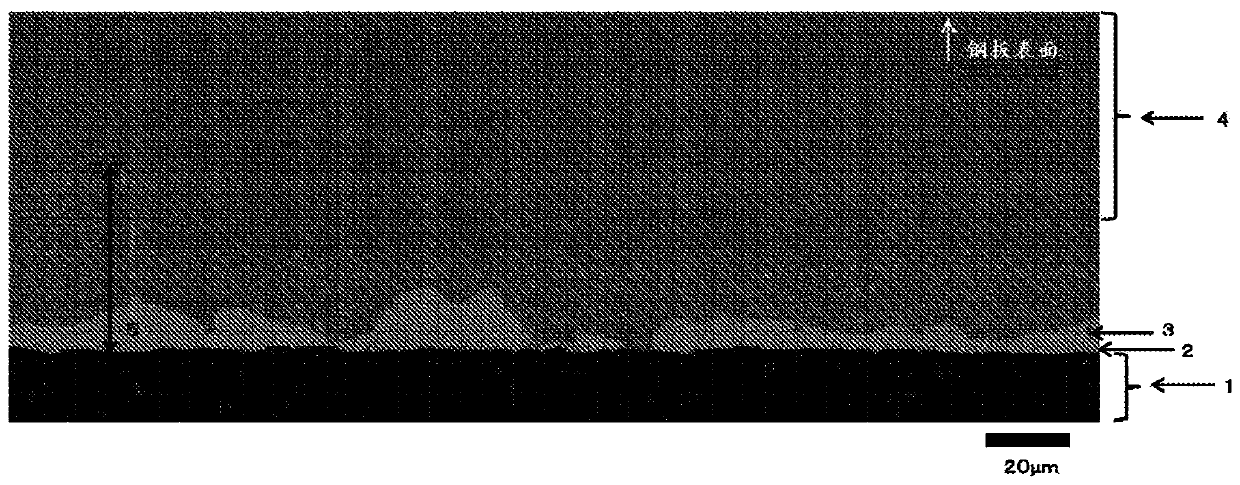

Image

Examples

Embodiment 1

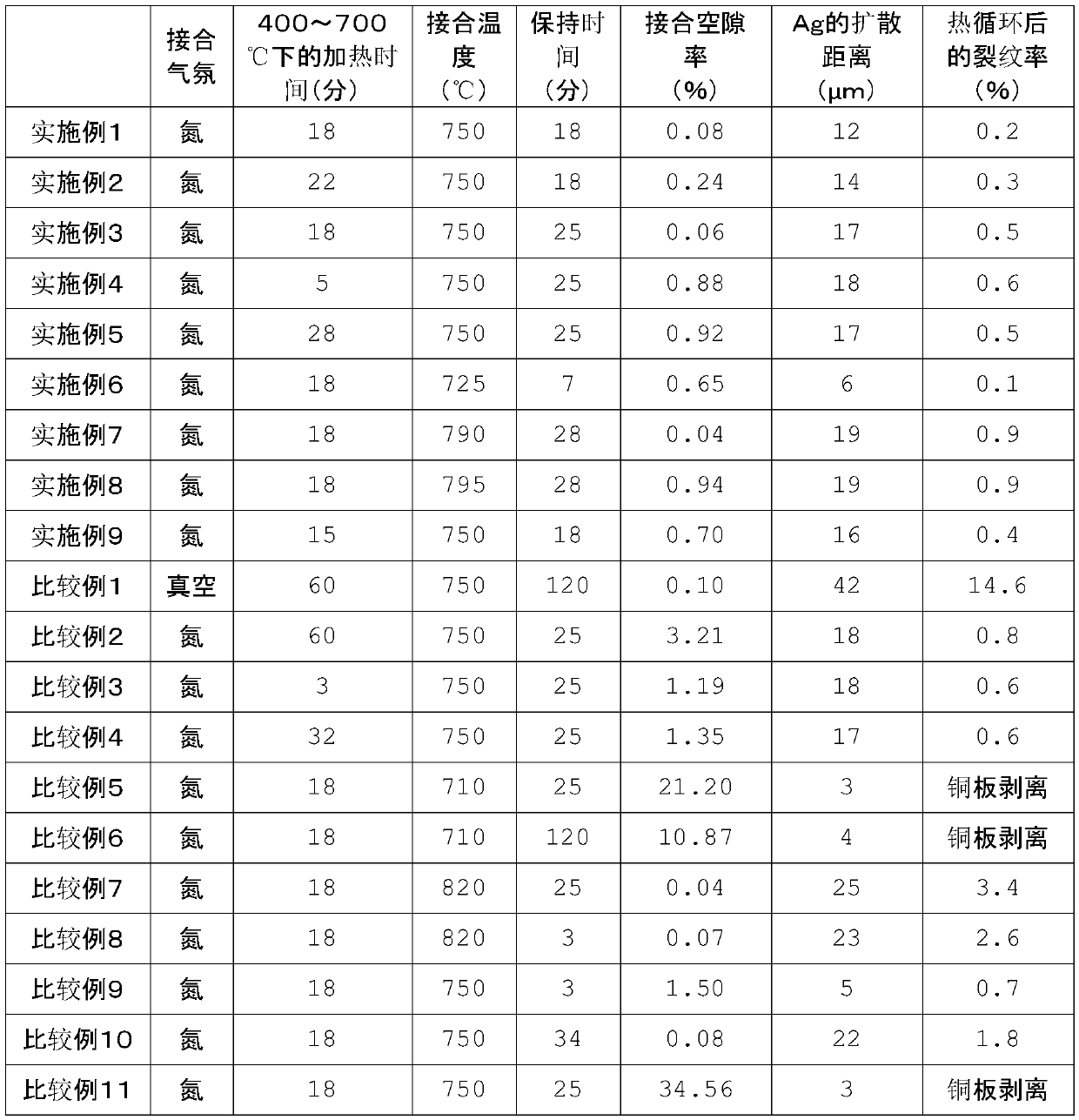

[0051] Using a roll coater, 88 parts by mass of Ag powder ("AgC-BO" manufactured by Fukuda Metal Foil Powder Industry Co., Ltd.) and 12 parts by mass of Cu powder ("SRC-Cu" manufactured by Fukuda Metal Foil Powder Industry Co., Ltd.) -20 ") of a total of 100 parts by mass of the mixture and mix 2.5 parts by mass of TiH 2 powder ("TSH-350" manufactured by Osaka Titanium Technology Co., Ltd.), 4 parts by mass of Sn powder ("Sn powder (-325 mesh)" manufactured by Mitsuwa Pharmaceutical Chemical Co., Ltd.), and the solder paste thus formed was prepared by 8mg / cm 2 The amount of coating is applied to a silicon nitride substrate with a thickness of 0.32mm. Then, a copper plate for forming a circuit was overlaid on one side of the silicon nitride substrate, and a copper plate for forming a heat dissipation plate (both oxygen-free copper plates with a thickness of 0.8 mm) was overlaid on the other side of the silicon nitride substrate, and they were put into a nitrogen atmosphere. T...

Embodiment 2~7、 comparative example 2~10

[0057] Ceramic circuit boards were obtained in the same manner as in Example 1 except that the bonding atmosphere, the heating time in the temperature range of 400° C. to 700° C., the bonding temperature, and the holding time were changed as shown in Table 1. Table 1 shows the measurement results.

Embodiment 8

[0059] A ceramic circuit board was obtained in the same manner as in Example 1 except that no Sn powder was added and the bonding temperature and holding time were changed as shown in Table 1. Table 1 shows the measurement results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com