Method and device for preparing semi-solid metal slurry by alternating magnetic field intensifying, overflowing and cooling

A semi-solid slurry and alternating magnetic field technology, applied in the field of semi-solid forming of metal materials, can solve the problems of increased operation complexity, complicated equipment design, reduced stability, etc., to achieve sufficient heat flow transfer, shorten pulping time, The effect of suppressing dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

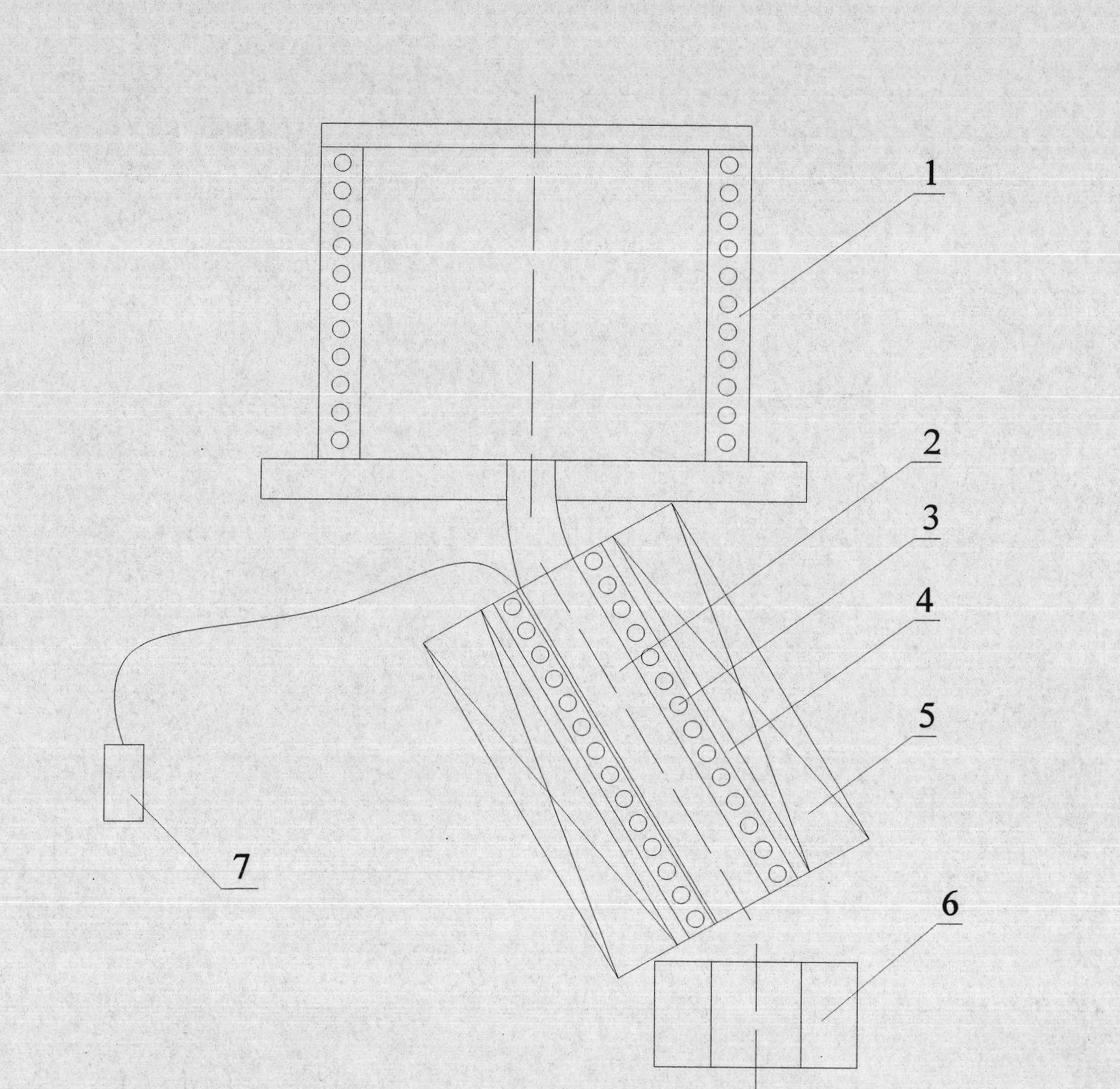

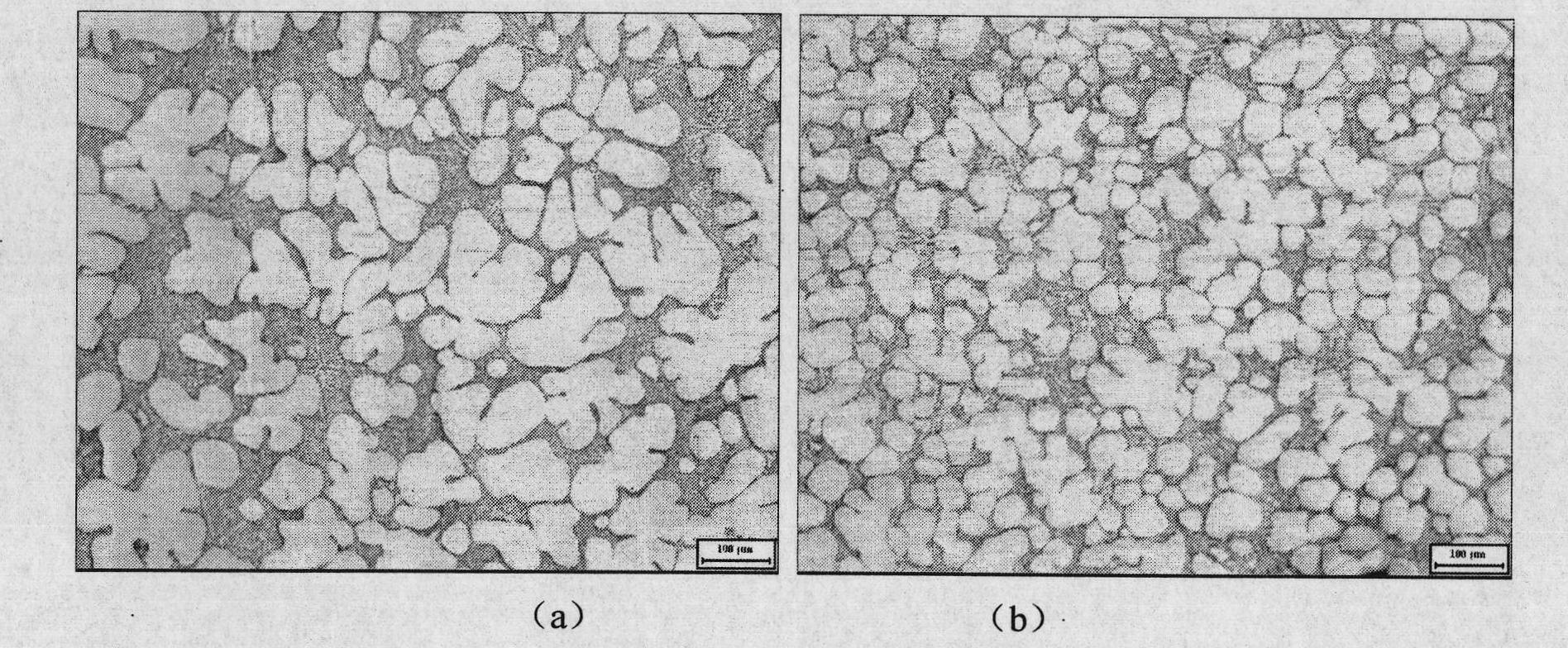

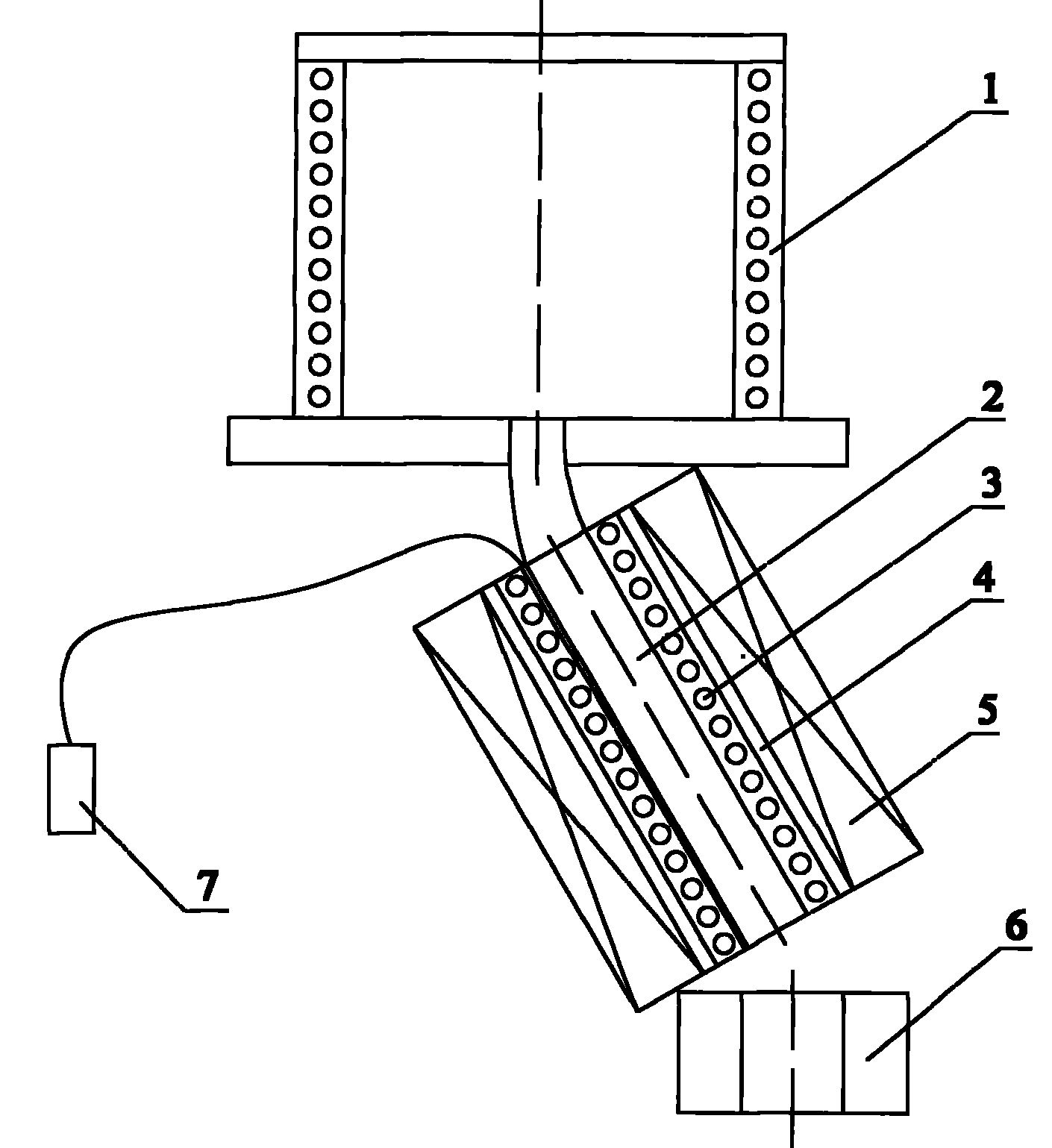

[0011] The alloy melt with a lower degree of superheat of 5-20°C in the holding furnace 1 is poured into the inclined tube 2, the preheating temperature of the inclined tube is 80-450°C, and its temperature is adjusted by the heating device 3 and the cooling device 4, Measured by thermocouple 7. An electromagnetic induction coil 5 is arranged outside the inclined tube to electromagnetically stir the overcurrent melt (an induced current is generated inside the melt to form an induced magnetic field, and the interaction between the two magnetic fields causes strong stirring inside the melt). The alloy melt flows through the inclined tube under the combined action of its own gravity and electromagnetic force, resulting in strong shear and chilling, which promotes the rapid nucleation and growth of the pro-eutectic phase and is crushed and refined to obtain high-quality metal semi-solid slurry . The slurry enters the crystallizer 6 for heat preservation, cooling and solidificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com