Brick combination soundproof wall

A technology for sound insulation walls and brick walls, which is applied in the field of composite walls to achieve the effects of convenient processing, good sound insulation and heat insulation, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

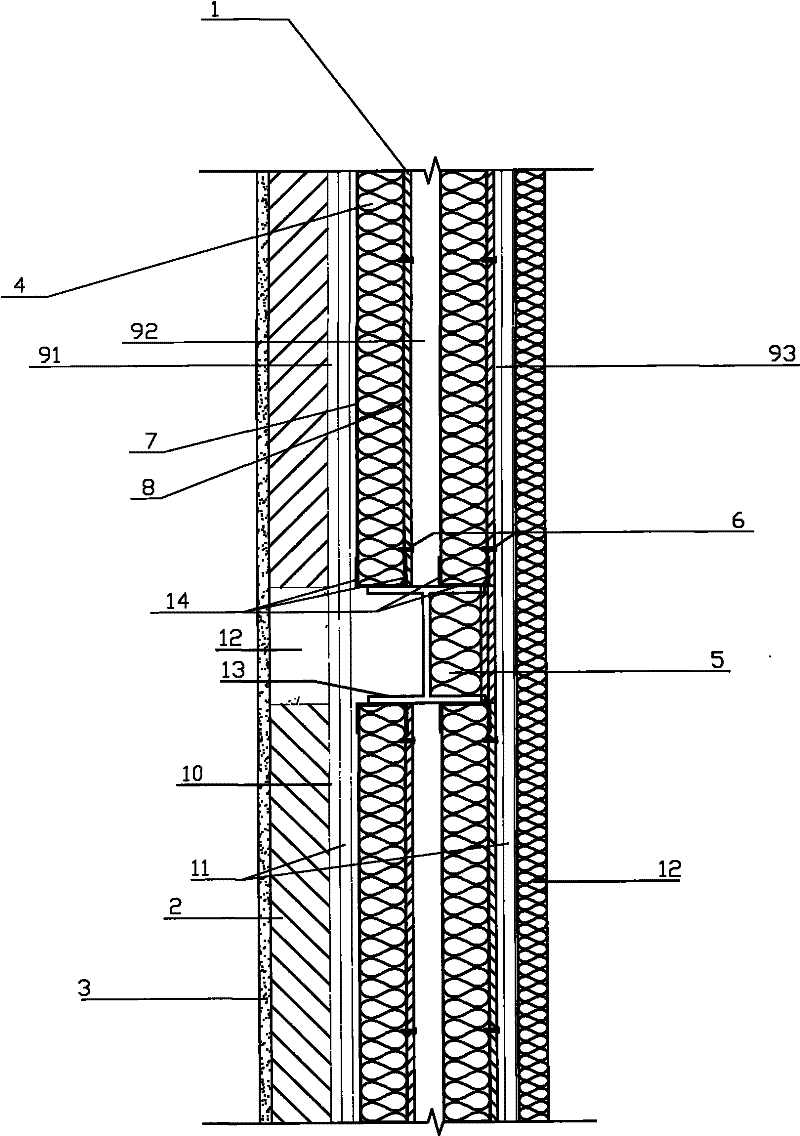

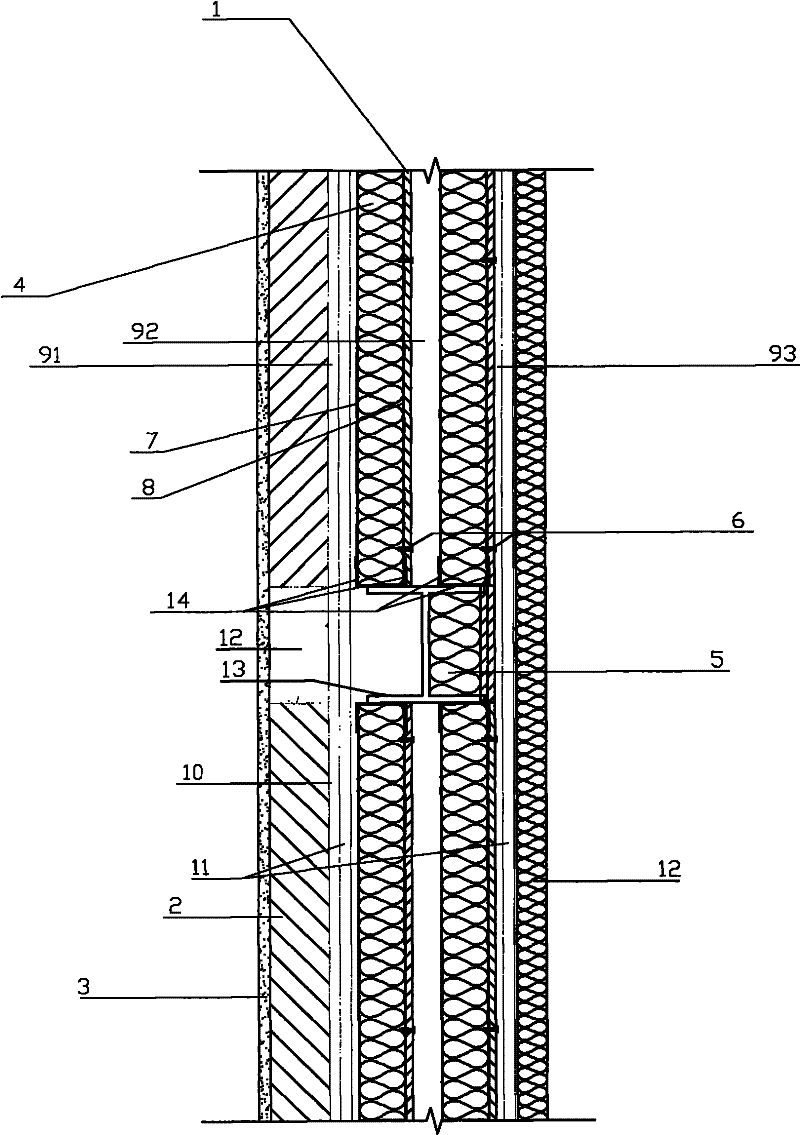

[0020] Such as figure 1 As shown, the brick combined sound insulation wall system of the present invention is composed of brick walls, rock wool sandwich boards, gypsum boards and sound-absorbing boards. The direction of the combined sound insulation wall system from the outside of the house to the inside of the house (the "outside" and "inside" refer to the same in the following) are:

[0021] A 100mm thick brick wall 2 has a 20mm thick 1:3 cement mortar plastering layer 3 (or double-sided plastering) on the outside of the brick wall 2; the inside of the brick wall 2 is a 50-100mm thick air layer 91.

[0022] The inner side of the air layer 91 is a two-layer rock wool sandwich board-gypsum board composite board, which is formed by closely adhering and fixing the outer rock wool sandwich board and the inner gypsum board 1.

[0023] The thickness of the rock wool sandwich panel is preferably 80 mm, and its two surfaces are color-coated steel plates, and the core material 4 is sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com