Double-valve fuel injecting device with electric-control monoblock pump and electric-control fuel injector

An electronically controlled fuel injection and fuel injection technology, which is applied to fuel injection devices with oil reservoirs, fuel injection devices, fuel injection pumps, etc., can solve the problems of deterioration of the combustion process, low fuel injection pressure, and low reliability, etc. To achieve the effect of suppressing mutual interference, reducing power and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

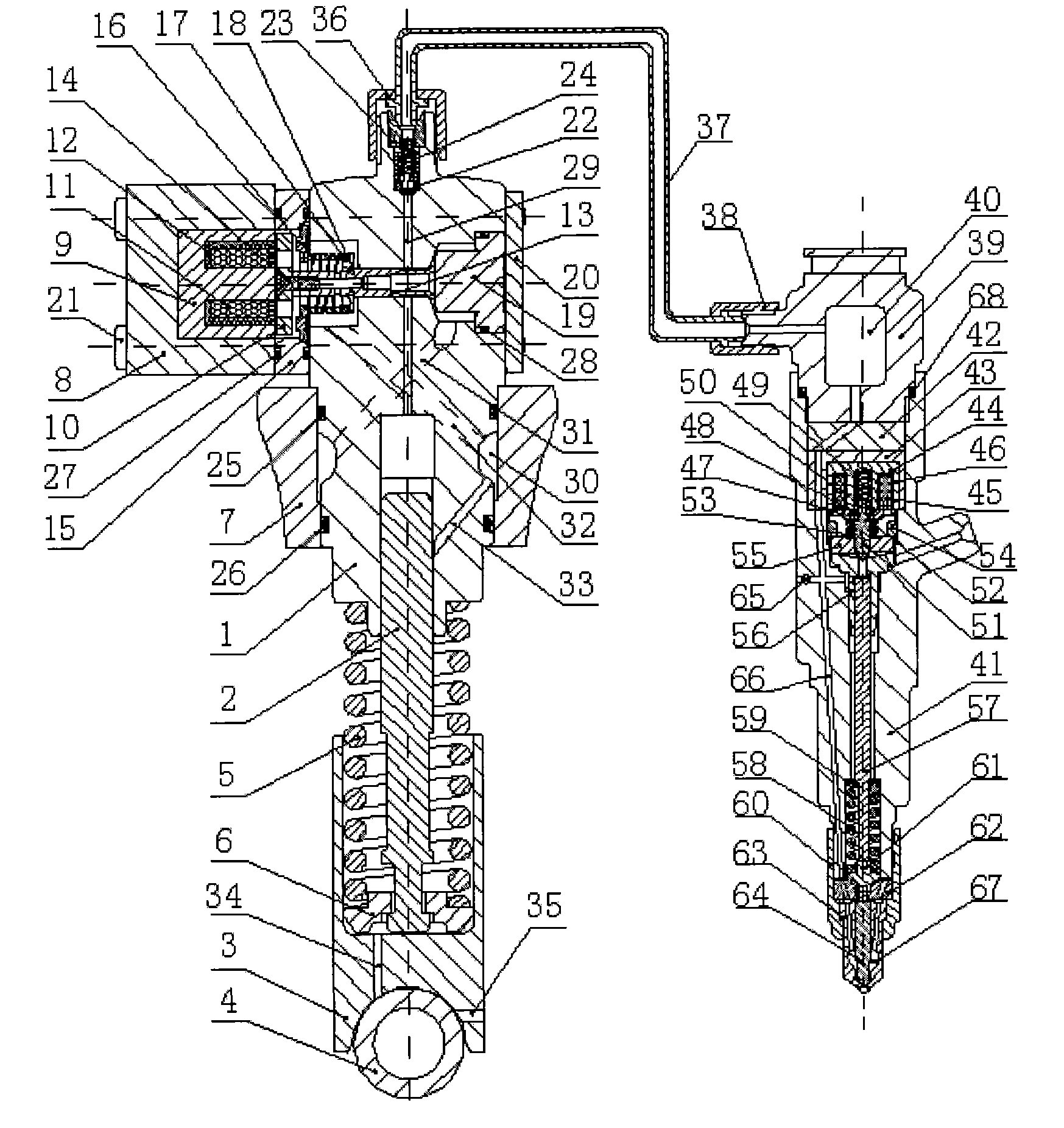

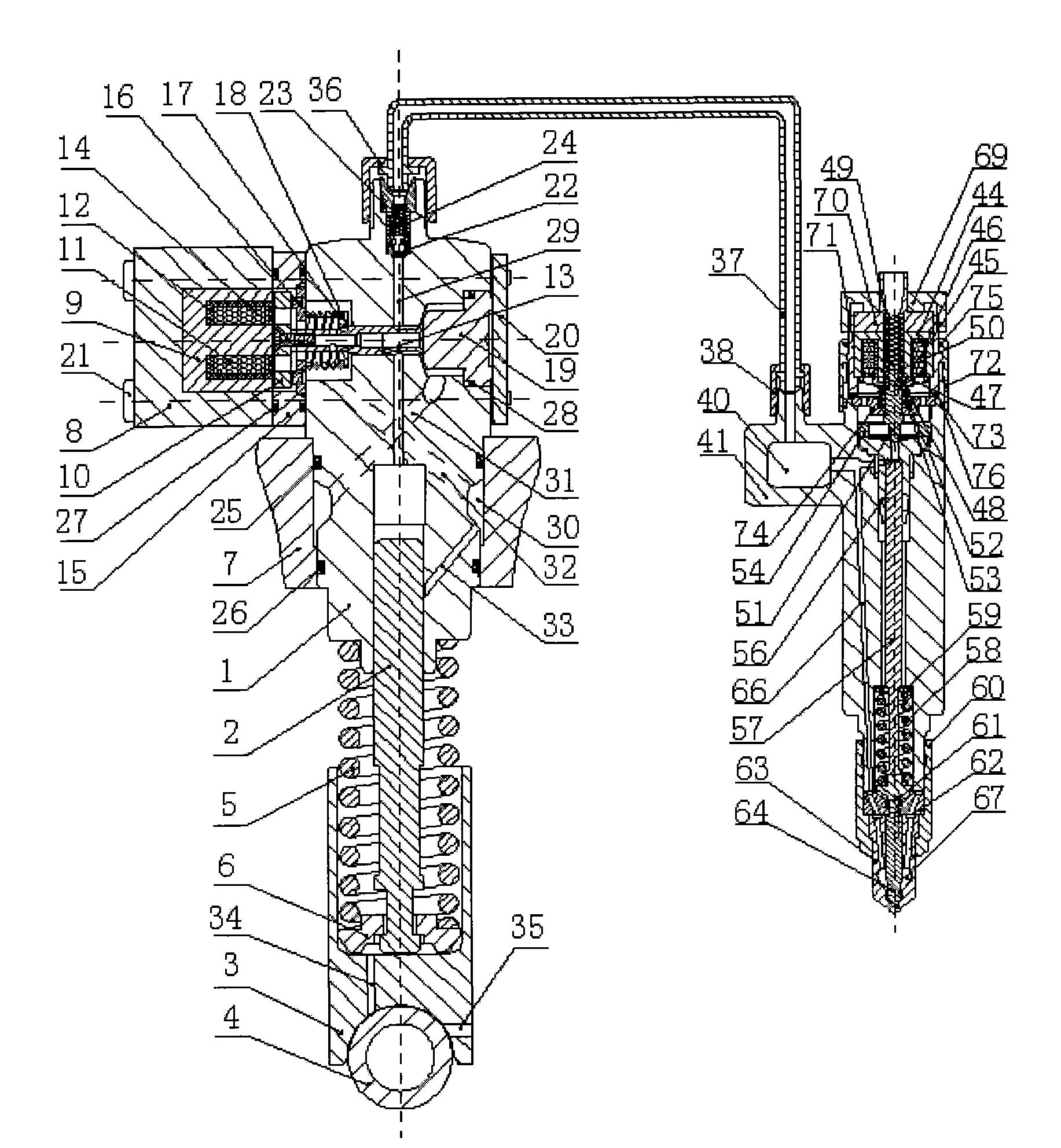

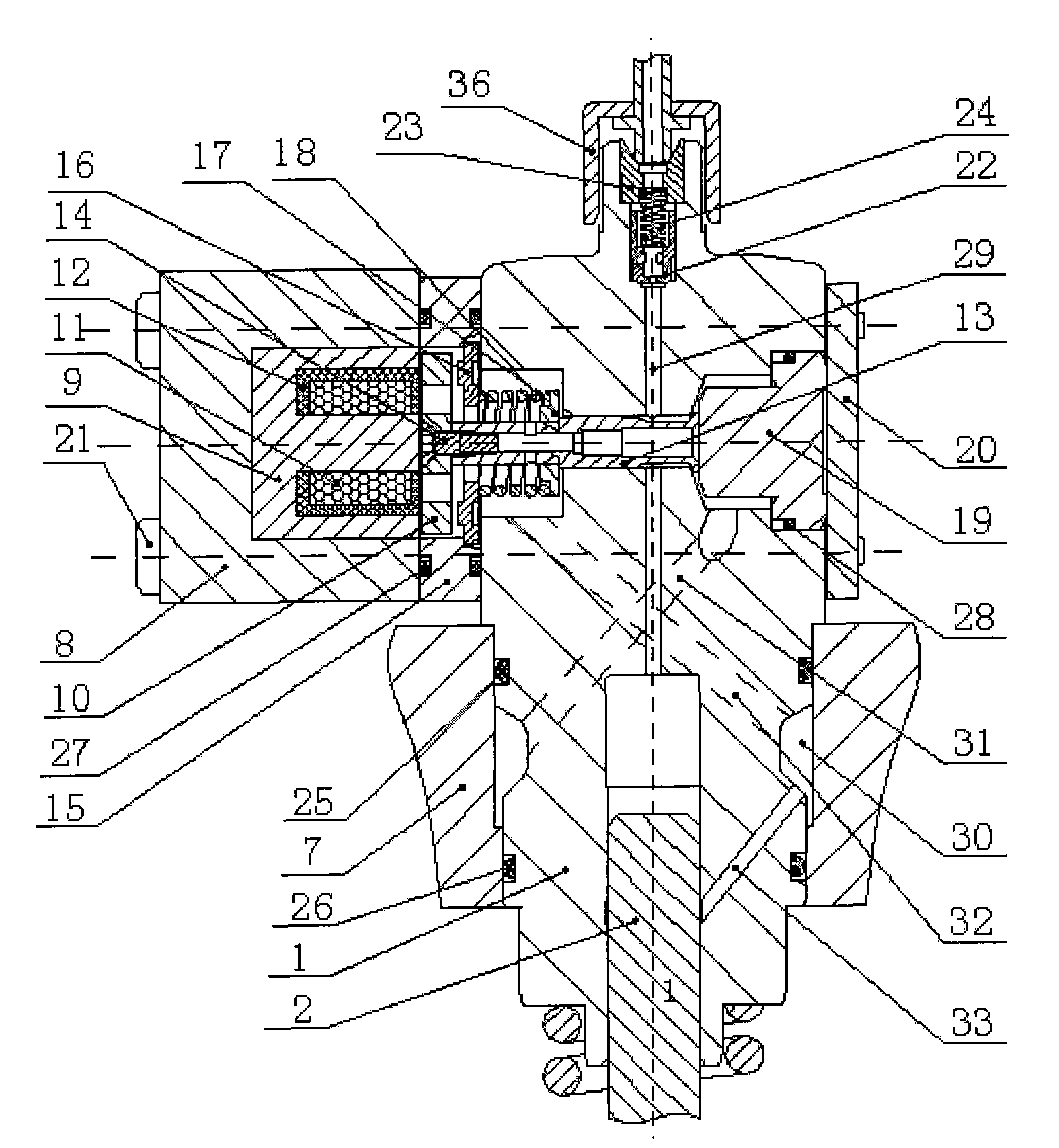

[0018] The pump body 1 of the electric control unit pump is installed in the pump box body 7, the control valve core 13 is installed in the valve core installation hole of the pump body 1, the solenoid valve body 8, the electromagnet 9, the armature 10, and the electromagnetic coil 11 , armature fastening screw 14, adjusting backing plate 15, block 16, control spool return spring 17, control spool spring seat 18, etc., together with control spool 13 constitute the oil supply solenoid valve control part of the monomer pump. The electromagnet 9, the adjusting backing plate 15 and the cover plate 20 are connected to the pump body 1 through the long bolts 21, and seal the fuel through the sealing rings 27 and 28. The pump body 1 is processed with a sealing tapered hole that fits with the sealing tapered surface of the control valve core 13, and this place is a fuel leakage channel. The armature 10 is integrated with the control spool 13 through the fastening screw 14, so that the ...

Embodiment approach 2

[0029] The pump body 1 of the electric control unit pump is installed in the pump box body 7, the control valve core 13 is installed in the valve core installation hole of the pump body 1, the solenoid valve body 8, the electromagnet 9, the armature 10, and the electromagnetic coil 11 , armature fastening screw 14, adjusting backing plate 15, block 16, control spool return spring 17, control spool spring seat 18, etc., together with control spool 13 constitute the oil supply solenoid valve control part of the monomer pump. The electromagnet 9, the adjusting backing plate 15 and the cover plate 20 are connected to the pump body 1 through the long bolts 21, and seal the fuel through the sealing rings 27 and 28. The pump body 1 is processed with a sealing tapered hole that fits with the sealing tapered surface of the control valve core 13, and this place is a fuel leakage channel. The armature 10 is integrated with the control spool 13 through the fastening screw 14, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com