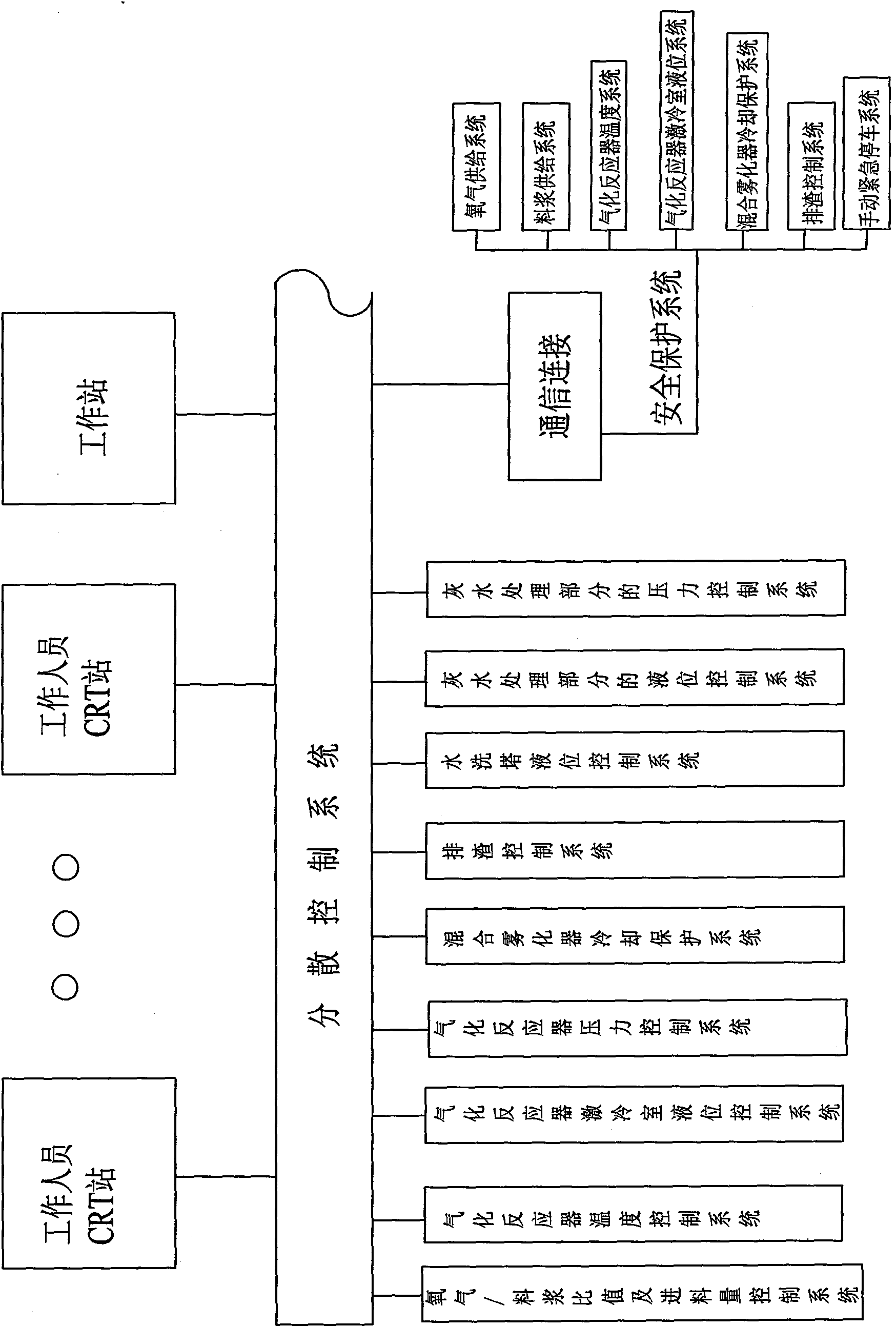

Control system for coal gasification technical process of wet entrained flow bed

A control system and process technology, applied in the field of coal gasification, can solve the problems of insufficient control system, low gasification production risk, low production efficiency, and insufficient advanced control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

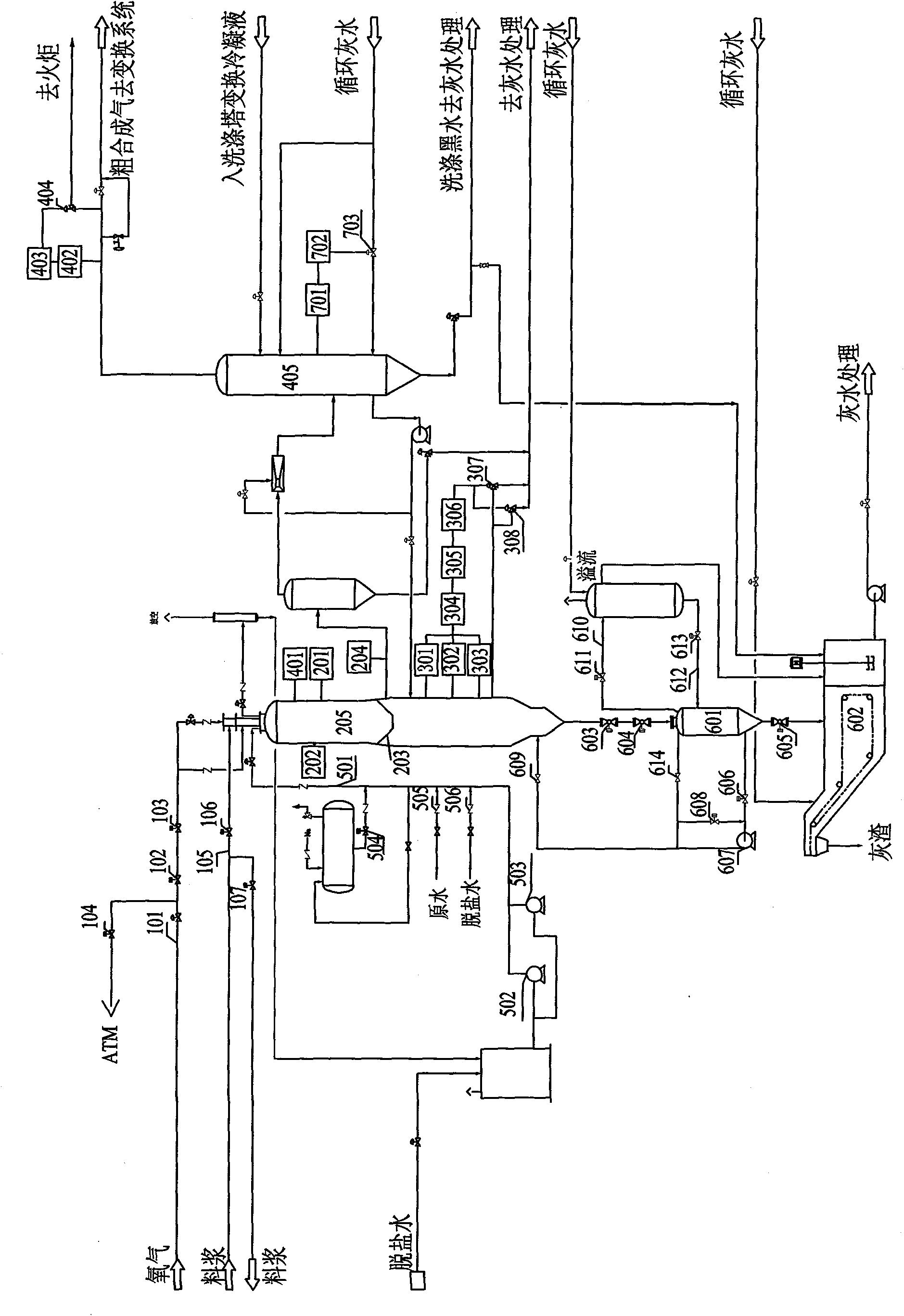

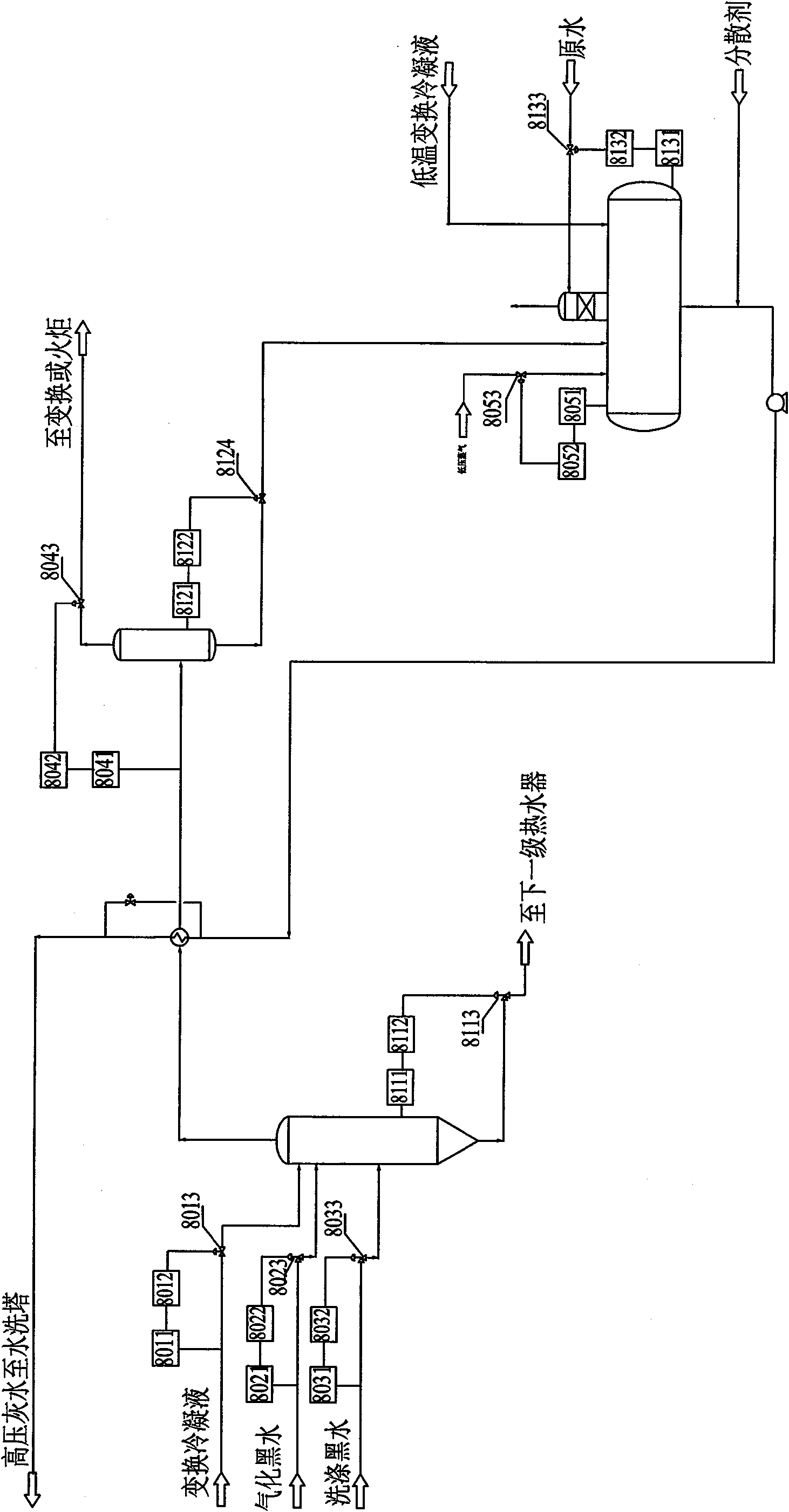

Method used

Image

Examples

Embodiment 1

[0196] A methanol plant with an annual output of 600,000 tons has a gasification pressure of 6.5MPa and a gasification temperature of 1360°C, using a certain coal as a raw material to implement the present invention. Effective gas CO+H from water washing tower 2 The content is 80.60%, the slurry concentration is 63.6%, and the operation cycle of the gasification device is more than 60 days.

[0197] Table 1 below shows the analysis results of the main coal quality data of a certain coal.

[0198] Table 1

[0199]

[0200] The coal gasification reaction utilizes the oxygen / slurry ratio provided in the present invention and the differential pressure transmitter produced by Shanghai Longruisi Electronic Technology Co., Ltd. provided by the feed control system to measure the oxygen flow rate to be 514m 3 / h, the oxygen flow after temperature and pressure compensation is 37721Nm 3 / h, the slurry flow measured by the electromagnetic flowmeter provided by Kaifeng Instrument Co....

Embodiment 2

[0225] A methanol plant with an annual output of 240,000 tons has a gasification pressure of 4.0 MPa and a gasification temperature of 1390°C, using a certain coal as a raw material to implement the present invention. Effective gas CO+H from water washing tower 2 The content is 79%, the slurry concentration is 58%, and the operation period of the gasification device is more than 60 days.

[0226] Table 2 below shows the analysis results of the main coal quality data of a certain coal.

[0227] Table 2

[0228]

[0229] The coal gasification reaction uses the oxygen / slurry ratio provided in the present invention and the differential pressure transmitter produced by Shanghai Longruisi Electronic Technology Co., Ltd. to provide the oxygen flow rate of 294m 3 / h, the oxygen flow after temperature and pressure compensation is 15954Nm 3 / h, the slurry flow measured by the electromagnetic flowmeter provided by Kaifeng Instrument Co., Ltd. is 33m 3 / h, after calculation, the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com