Method for preparing of compound trapping layer in floating gate type nonvolatile storage

A non-volatile and memory technology, applied in semiconductor/solid-state device manufacturing, coating, nanostructure manufacturing, etc., can solve the problems of high cost, complicated manufacturing, unfavorable industrial realization, etc., to reduce manufacturing cost and simplify the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

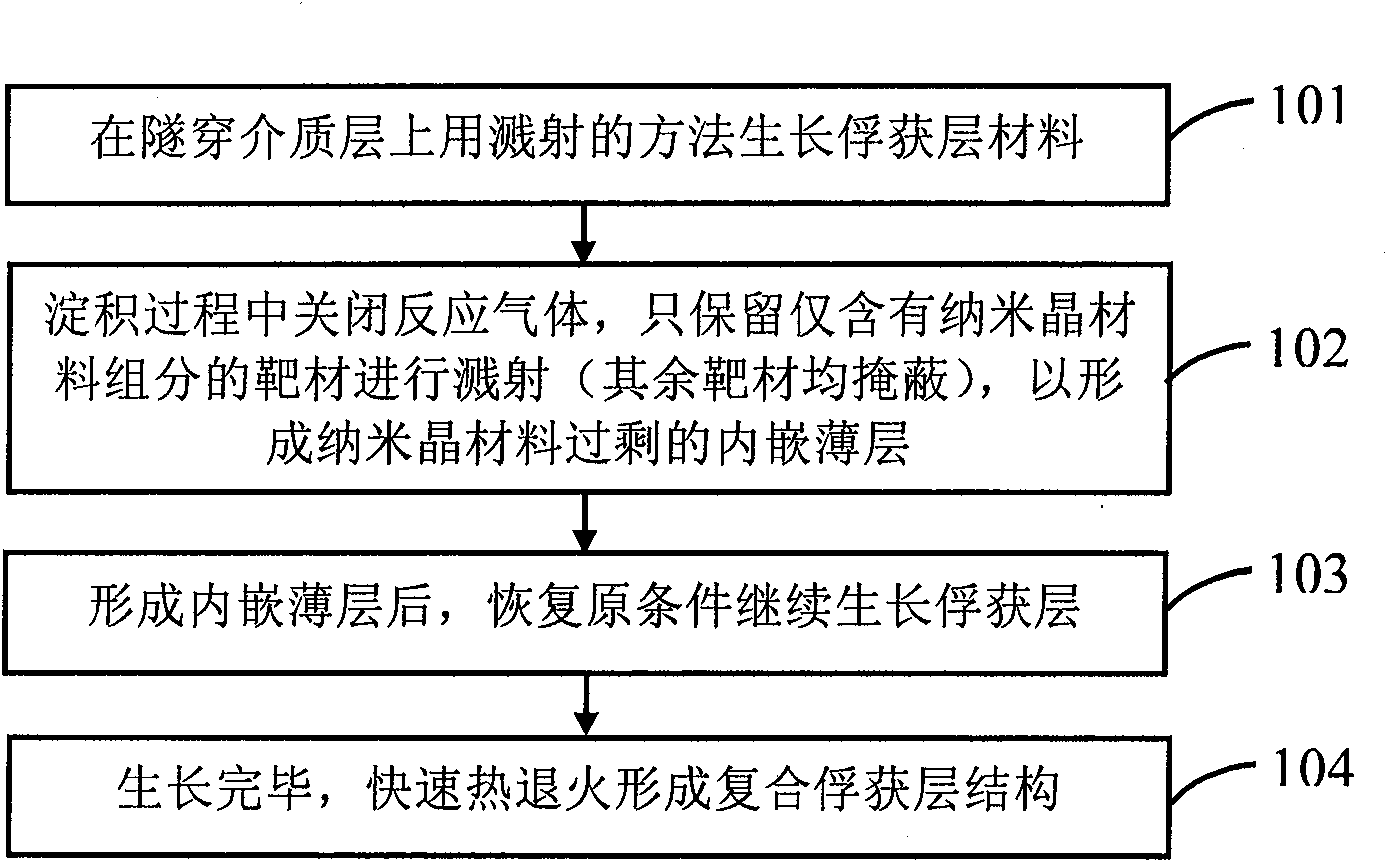

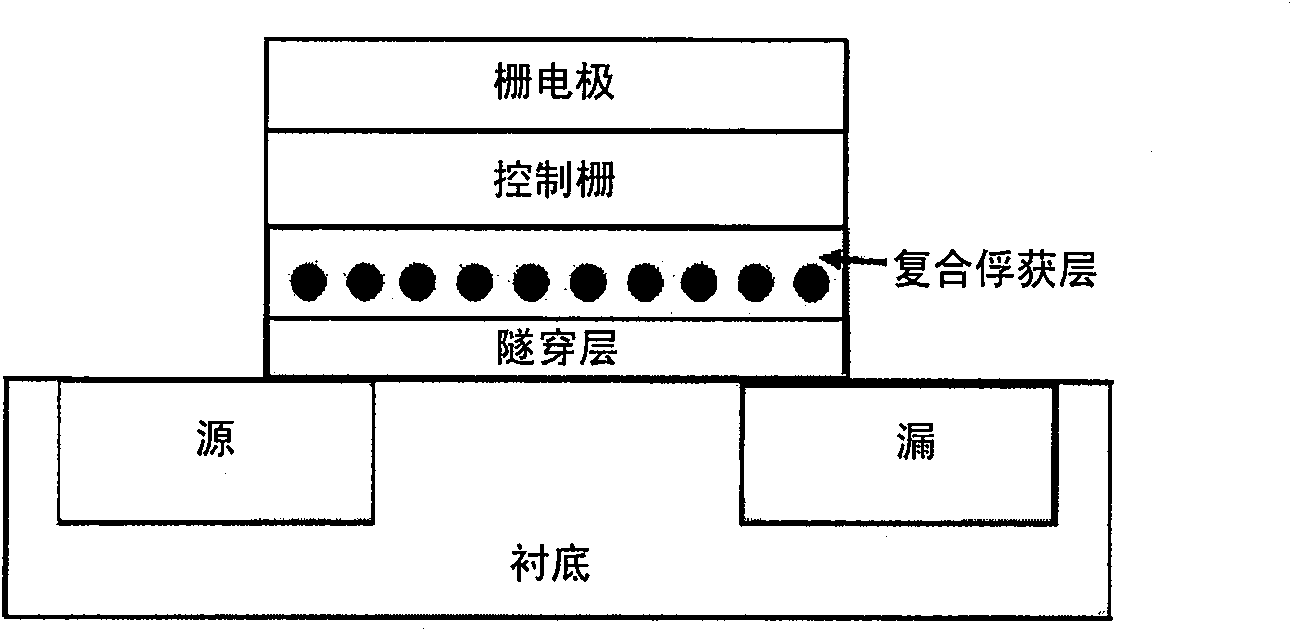

[0031] figure 1 It is a flowchart of a method for preparing a composite trapping layer in a floating gate type nonvolatile memory provided by the present invention, and the method includes:

[0032] Step 101: using a sputtering process to co-sputter various targets on the tunneling dielectric layer to deposit growth trapping layer media;

[0033] Step 102: Covering other targets during the sputtering process, sputtering a certain target material alone, forming a thin layer of embedded nanocrystals with excess nanocrystal materials in the capture layer;

[0034] Step 103: After forming the embedded nanocrystalline thin layer, restore the original process conditions (that is, the process conditions in step 1) and continue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com