Charging circuit for lead acid batteries with high power factors

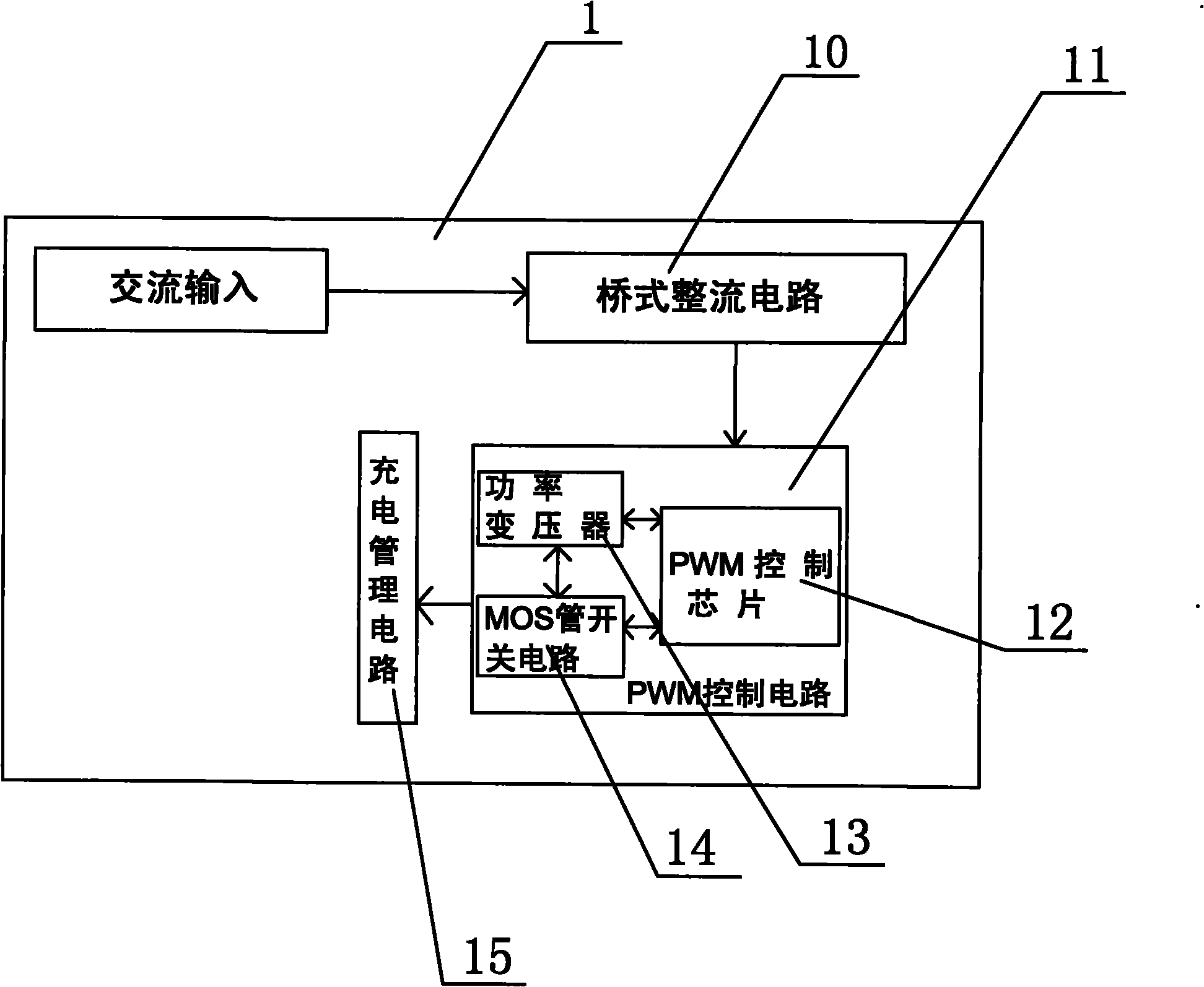

A high power factor, lead-acid battery technology, applied in battery circuit devices, high-efficiency power electronic conversion, circuit devices, etc., can solve the problems of no power factor correction compensation, complex circuit structure, poor power quality, etc., and achieve high conversion. Efficiency, simple circuit structure, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

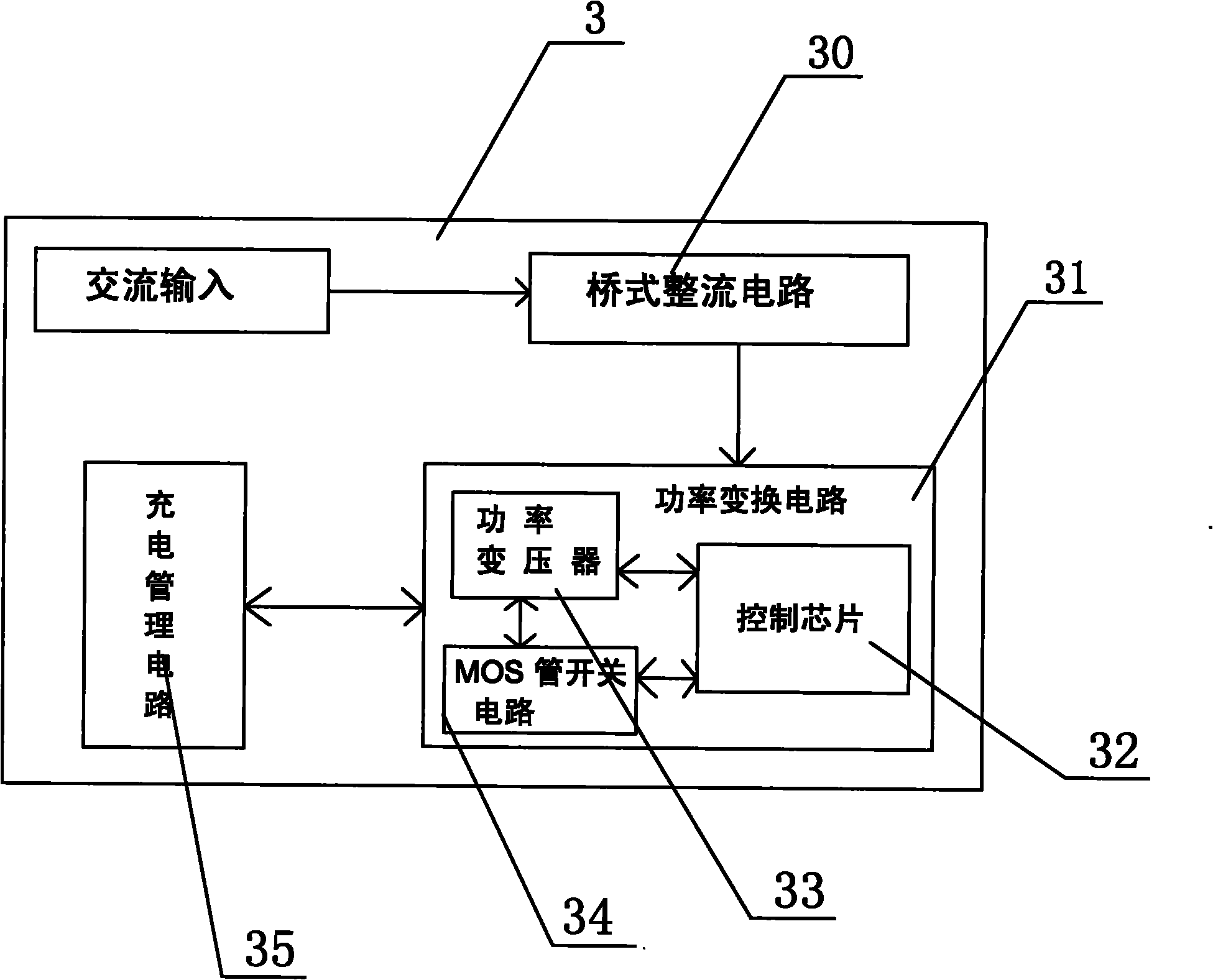

[0018] see image 3 and Figure 4 as shown, image 3 Be the block diagram of high power factor lead-acid battery charging circuit of the present invention, Figure 4 It is a specific circuit diagram of the high power factor lead-acid battery charging circuit of the present invention.

[0019] A high power factor lead-acid battery charging circuit, the high power factor lead-acid battery charging circuit 3 includes a bridge rectifier circuit 30, a power conversion circuit 31 and a charging management circuit 35, and the bridge rectifier circuit 30 is coupled to a power conversion circuit 31, the power conversion circuit 31 is coupled to the charging management circuit 35, the power conversion circuit 31 includes a control chip 32, the control chip 32 is coupled to a power transformer 33 and a MOS tube switch circuit 34, and the model of the control chip 32 is SG6961 Chip U1, which includes pin 1-pin 8, the power transformer T1 includes a transformer primary winding, a transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com