Polyester bottle with resistance to heat and pressure and process for producing the same

A production method, heat-resistant technology, applied to bottles, rigid containers, and other household appliances, etc., can solve the problems of reducing thickness and reducing weight, and achieve the effect of improving pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

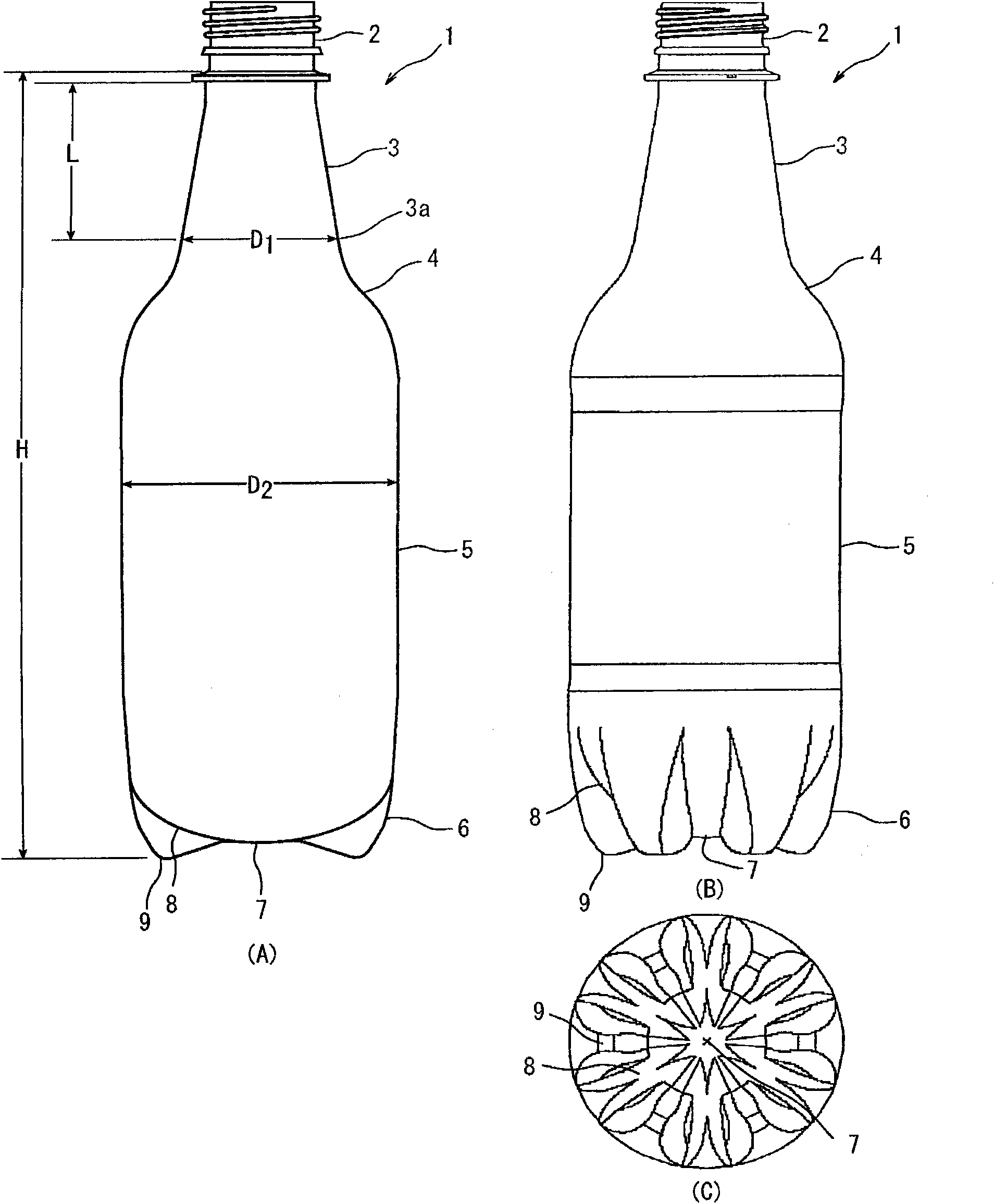

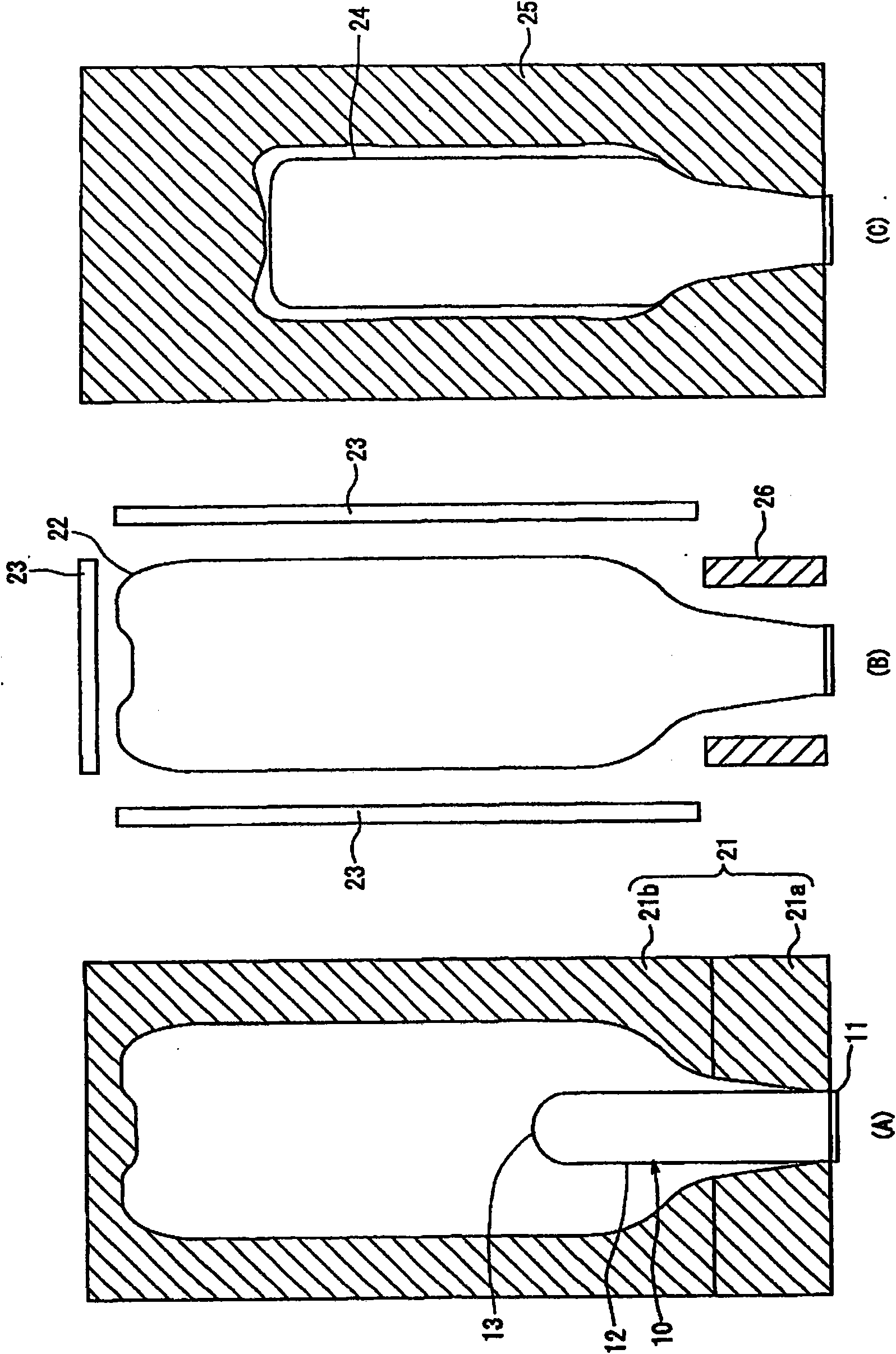

[0099] Homopolyethylene terephthalate (intrinsic viscosity, 0.78 dL / g) used as a raw material was molded into a preform weighing 33 g and having a mouth satisfying the shape of a screw cap by using an injection molding machine.

[0100] The preform was heated at 110°C and primary blow molded at a mold temperature of 25°C for the neck and 120°C for the body to obtain a primary molded product having a diameter of 72 mm in its body.

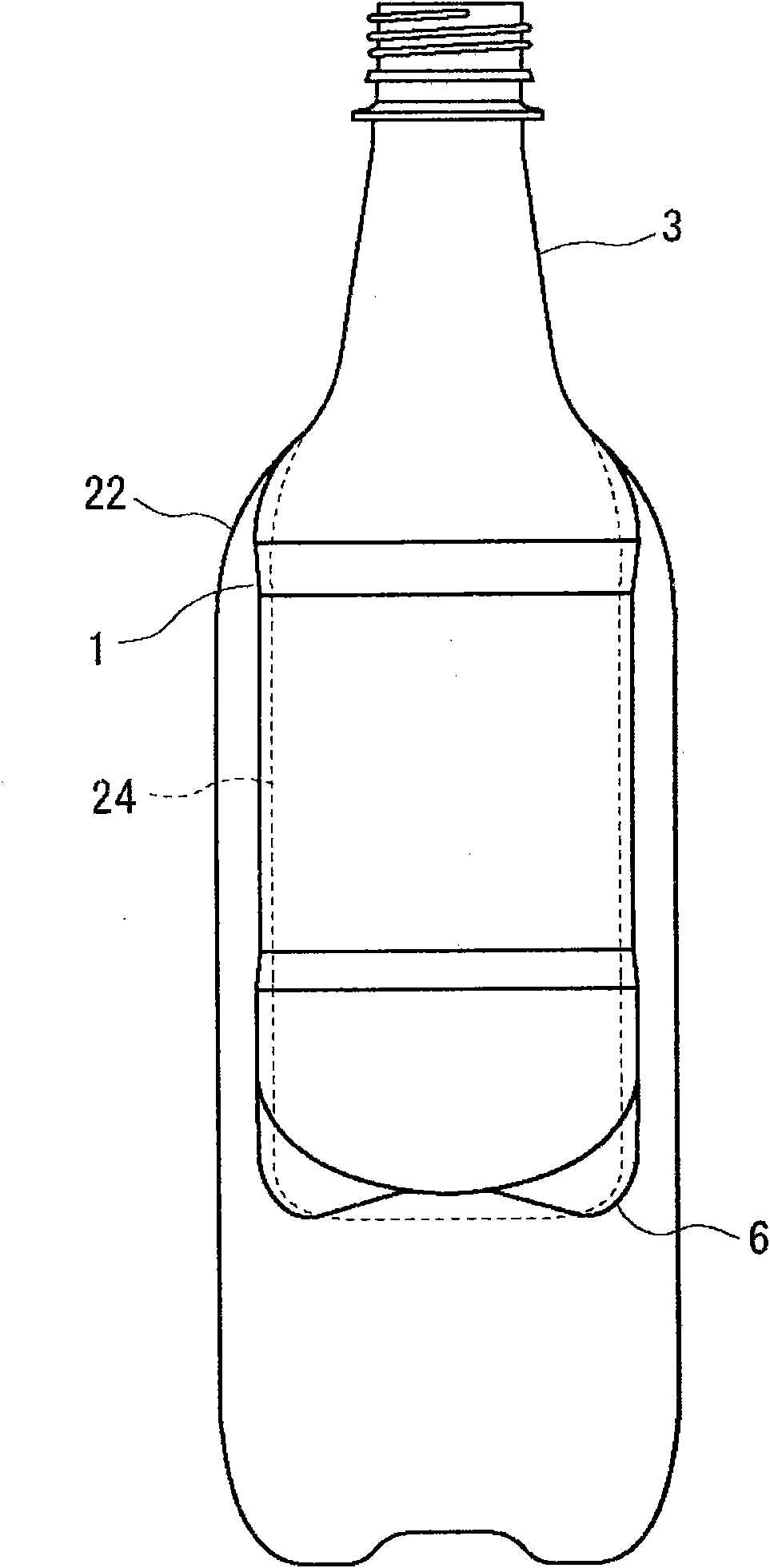

[0101] The secondary molded product is obtained by heating the primary molded product so that the body temperature of the primary molded product is 170°C and heat-shrinks, and the secondary molded product is immediately subjected to secondary blow molding at a metal mold temperature of 25°C . A bottle molded into a final molded product having a bottle height excluding the mouth of 210 mm, a neck length of 44 mm, a body diameter of 65 mm, a filling capacity of 530 ml, a body thickness of 0.3 mm, and a position 15 mm from the center of the bottom towa...

Embodiment 2

[0103] A bottle of the same shape was molded in the same manner as in Example 1 except that the diameter of the body of the primary molded product was set to 76 mm. The amount of processing is 19%.

Embodiment 3

[0105] A bottle of the same shape was molded in the same manner as in Example 1 except that a copolymerized polyethylene terephthalate (intrinsic viscosity, 0.80 dL / g) containing an isophthalic acid component of 1.3 mol% was used as inner and outer layers, and using 5% by weight of an oxygen-absorbing resin containing a polyamide resin as a base material as an intermediate layer, a multilayer preform was molded by using a co-injection molding machine. The amount of processing is 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com