Nano silver-super absorbent polymer composite and radiation method production technology

A technology of super absorbent resin and composite material, applied in the field of new radiation chemistry materials, can solve the problems of small contact area between chips and germ carriers, smaller resin water absorption ratio, inability to kill germs, etc., and achieves excellent sterilization effect. , excellent bacteriostatic effect, narrow particle size distribution effect

Inactive Publication Date: 2010-08-25

安徽华晶新材料有限公司

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are also individual manufacturers who attach nano-silver to the film, cut the film into small pieces as chips, and stack the chip and superabsorbent resin together. The disadvantage is that the contact area between the chip and the germ carrier is small and cannot be killed. Bacteria that have infiltrated the resin

6. Problems in the preparation process of nano silver-superabsorbent resin composite materials

In 2001, Chen Wenming, University of Science and Technology of China, etc. used the in-situ generation method (Chen called the radiation hydrogel method) to prepare nano-silver-superabsorbent resin composite materials in experimental research. The disadvantage is that there are many preparation processes and follow-up The irradiation makes the water absorption ratio of the resin smaller (Journal of University of Science and Technology of China, 2001, 31(5): 6, 590-595, metal-polymer nanocomposites prepared by radiation hydrogel method)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

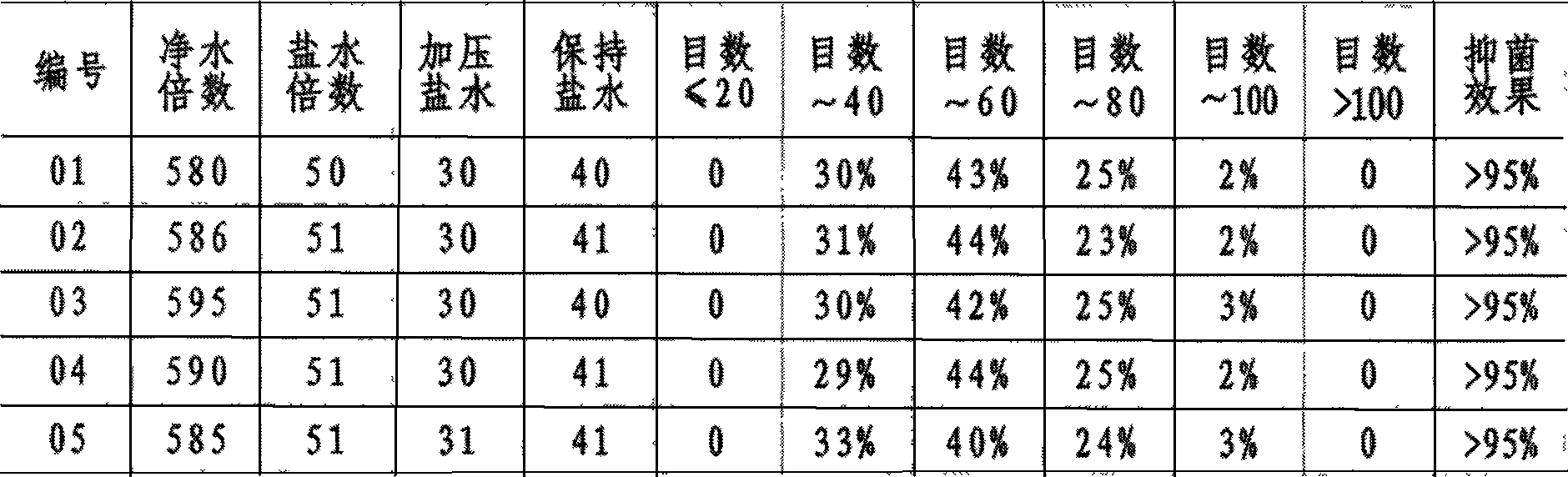

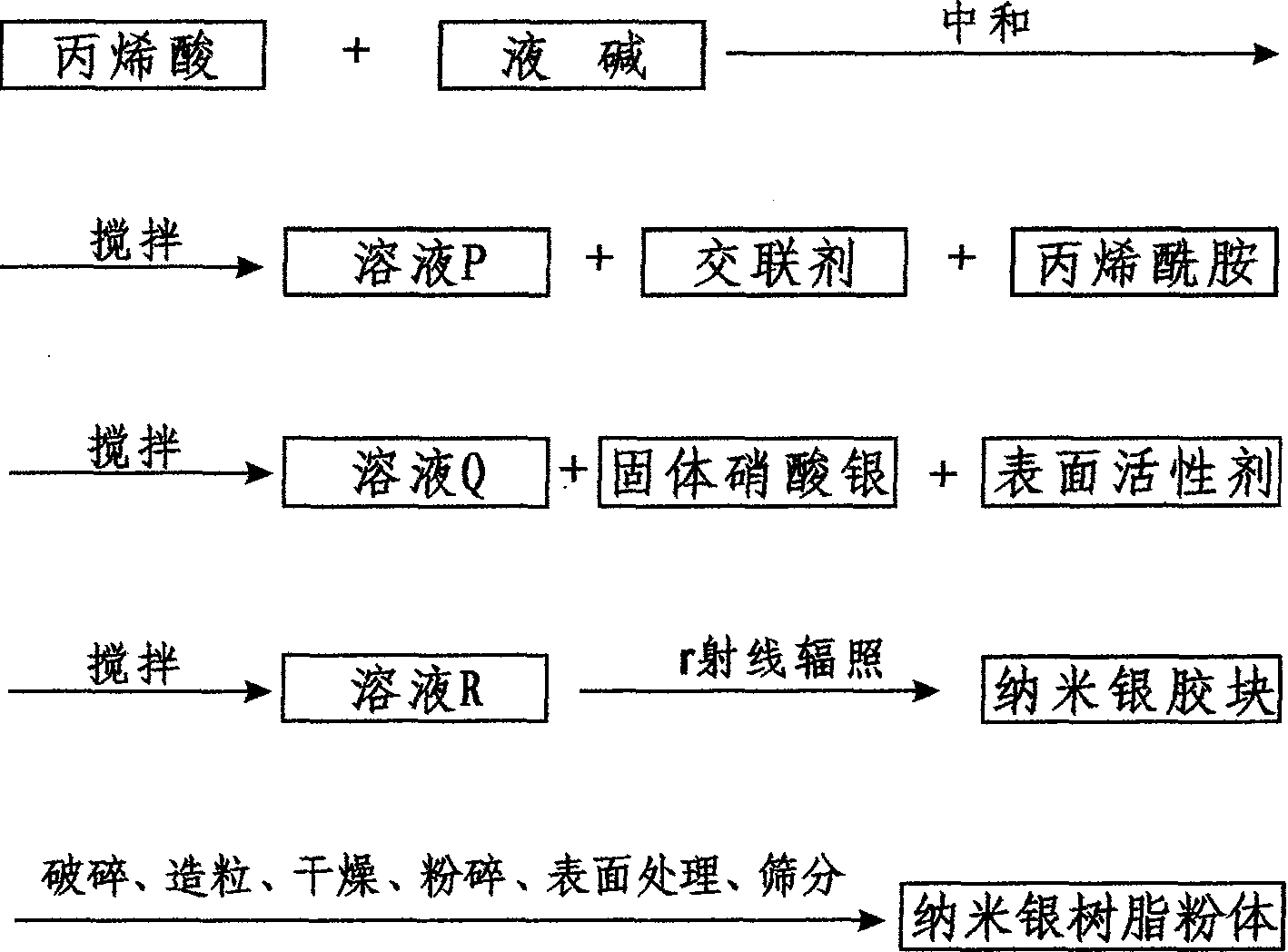

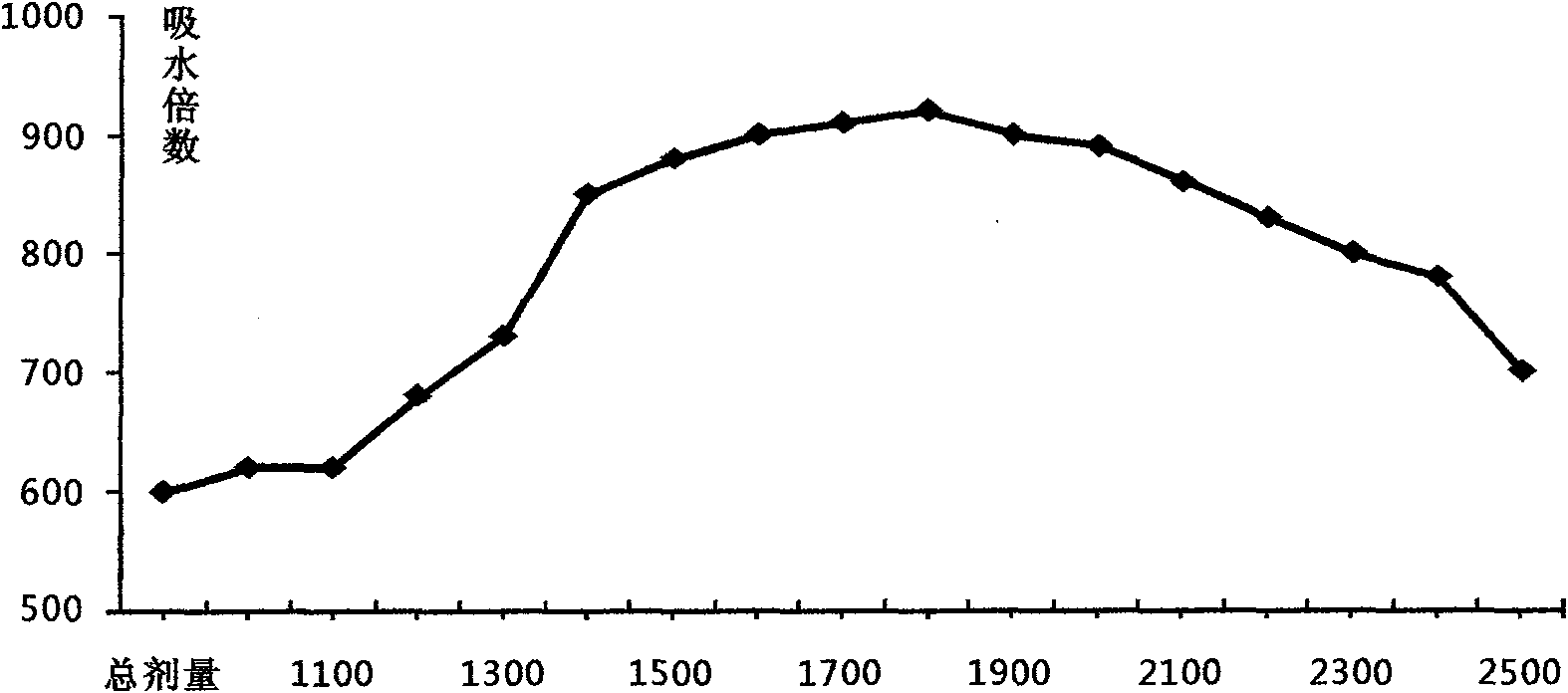

The invention discloses a nano silver-super absorbent polymer composite serving as the main function material of physical hygiene articles, and the grain diameter is less than or equal to 100 meshes. Nano silver grain of which the grain diameter is less than or equal to 100 nm is compounded in three-dimensional network structure of which the edge length is less than or equal to 10 nanometers; the network does not affect exchange of internal medium and external medium, nano silver grains of which the content is not less than 50 ppm and better value is 170 ppm are evenly distributed in resin and have excellent sterilizing effect. The radiation method production technology of the composite is characterized in that cross-linking agent is added when preparing super absorbent polymer feed solution and the mixture is evenly stirred; then, silver nitrate and surfactant are added, wherein the density of silver nitrate is between 10-4 and10-1M and the density of surfactant is between 10 and 3-2 M; and at normal temperature, the mixture is irradiated by r-ray of Co-60 of which the dose rate is 10-200 Gy / min, and total irradiation dose is 1-15 KGy so as to obtain the nano silver-super absorbent polymer composite. The preparation method is the only one-step synthesis technology currently and is applied to industrial volume production.

Description

technical field Both high-energy electron beams and gamma-rays can ionize matter, commonly known as ionizing radiation. The present invention relates to an inorganic-polymer nanocomposite material (polymer-based metal nanosilver composite material) and a production method thereof, especially to prepare nanosilver-superabsorbent resin composite material by using cobalt-60 gamma-rays and electron beams , belonging to the field of radiation chemical new materials. Background technique 1. Product application background. Sanitary napkins and diapers have become daily necessities for the general public. Absorbent paper and medical pads are also widely used in society. Their main functional materials are superabsorbent resins. Superabsorbent resin has super water absorption capacity and water retention capacity. It can absorb deionized water hundreds or even thousands of times heavier than itself or 0.9% salt water dozens or even hundreds of times heavier than itself, and can kee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L101/14C08K3/08C08L33/02C08L33/26C08F2/46C08F2/44A61L15/24A61L15/18A61L15/60

Inventor 陈文明刘振

Owner 安徽华晶新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com