Vertical dry-process anaerobic fermentation device

A technology of dry anaerobic and fermentation equipment, applied in the field of energy utilization and environmental protection, to achieve the effect of increasing gas production rate and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

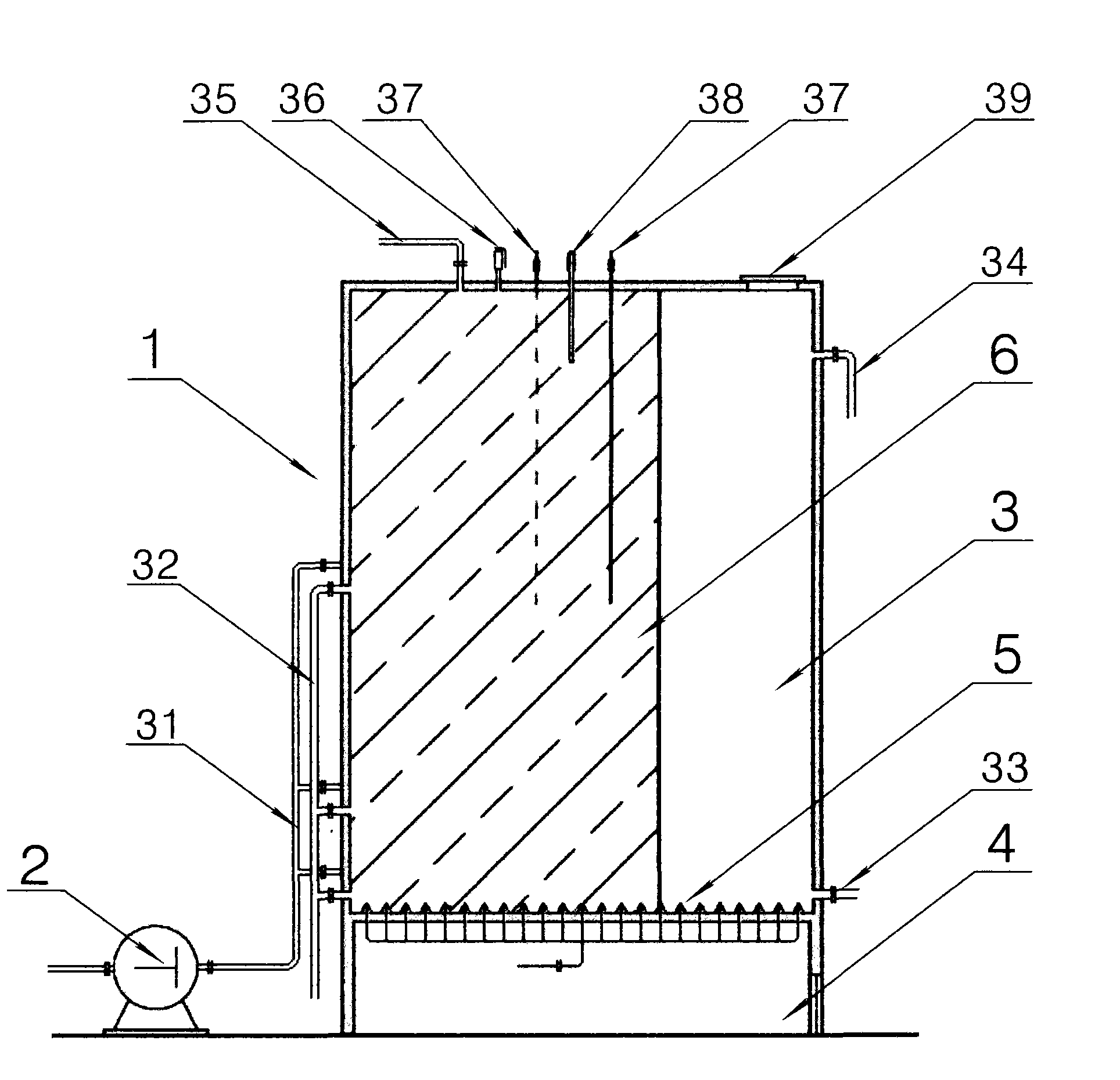

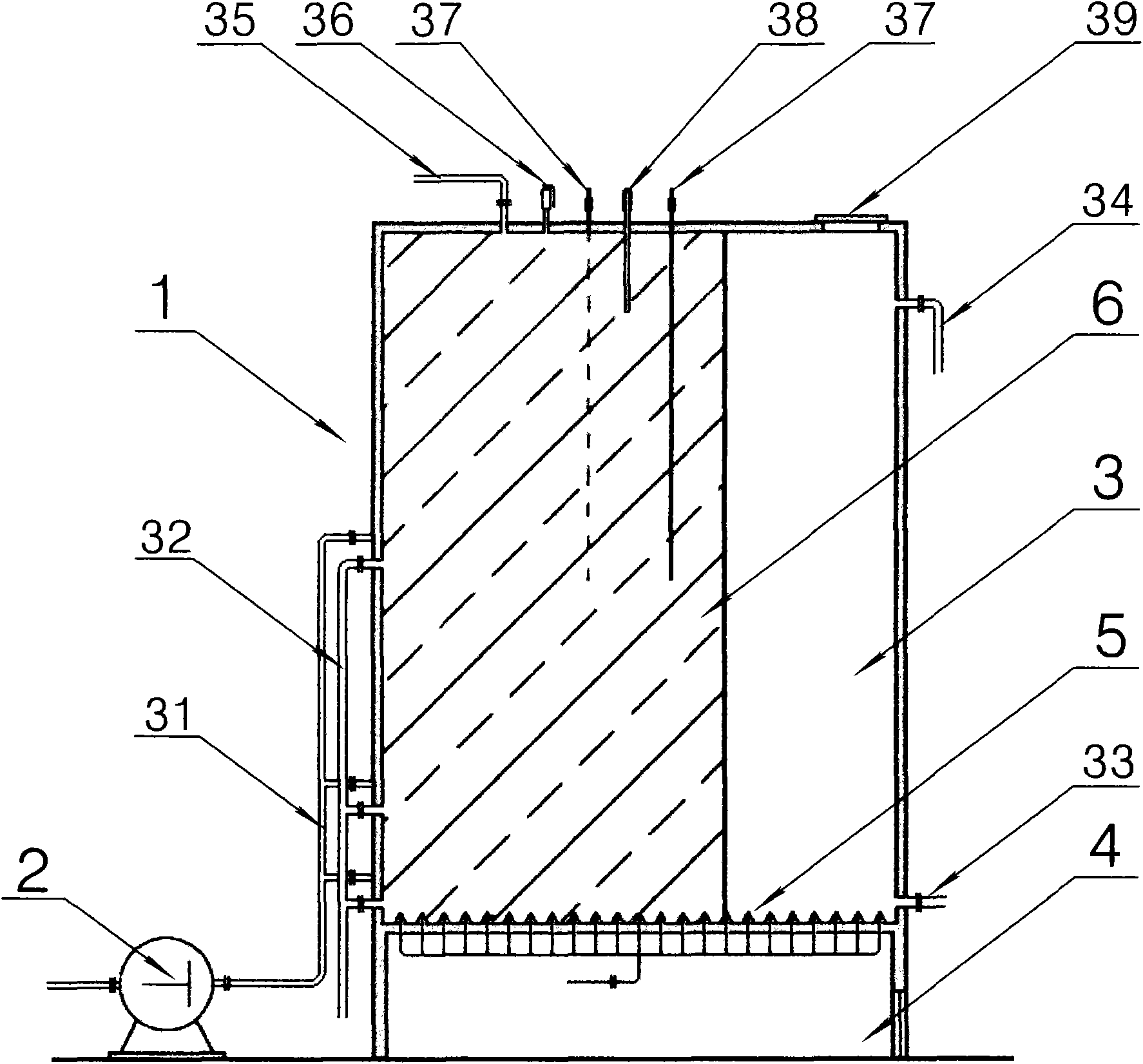

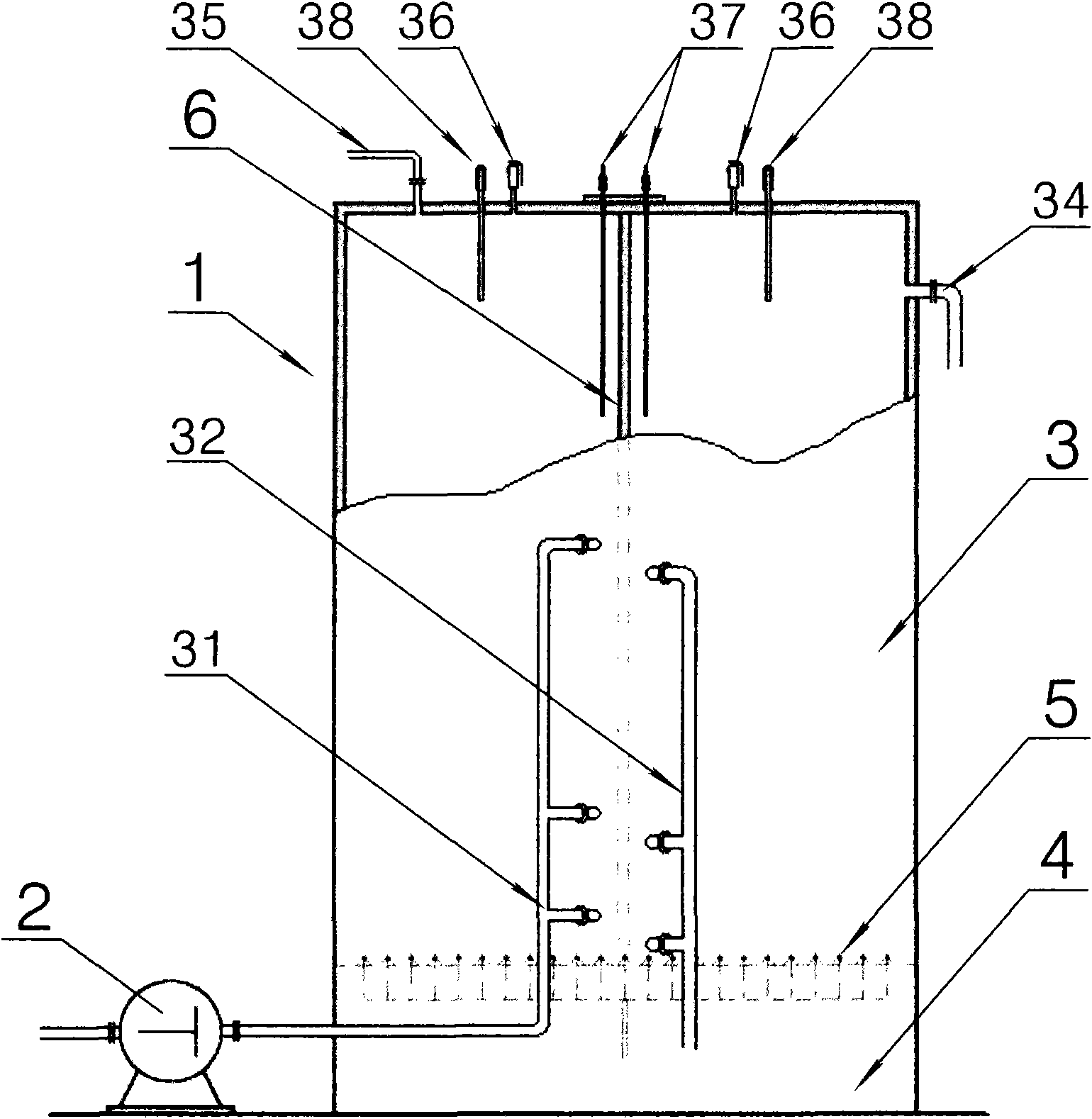

[0011] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is further elaborated: the organic waste that reaches reaction requirement through pretreatment is pumped into reaction container 3 by feed pump 2 through feed port 31, and its feed pump 2 adopts to be able to convey high For reciprocating pumps, rotor pumps or screw pumps with concentrated and high-viscosity substances, the feeding operation can be continuous or semi-continuous. The fermented material enters the reaction vessel 3 and moves forward in a horizontal direction. Due to the partition effect of the partition wall 6, it must run around the circumference of the reaction vessel 3 to reach the discharge port 32, effectively preventing the short circuit of the fermented material. Along the circumferential direction in the reaction vessel 3, a plug-flow reaction state is formed to prolong the period of the fermentation reaction. At the same time, through the nozzle 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com