Analysis and Monitoring Method of Blast Furnace Lining Erosion

A blast furnace lining, boundary integral equation technology, applied in blast furnace, blast furnace details, blast furnace parts, etc., can solve the problem that cannot fully reflect the full state and erosion degree of the hearth, the number of ceramic or metal rods is limited, and there are few online continuous measurements, etc. problems, to achieve good technical and economic indicators, saving calculation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

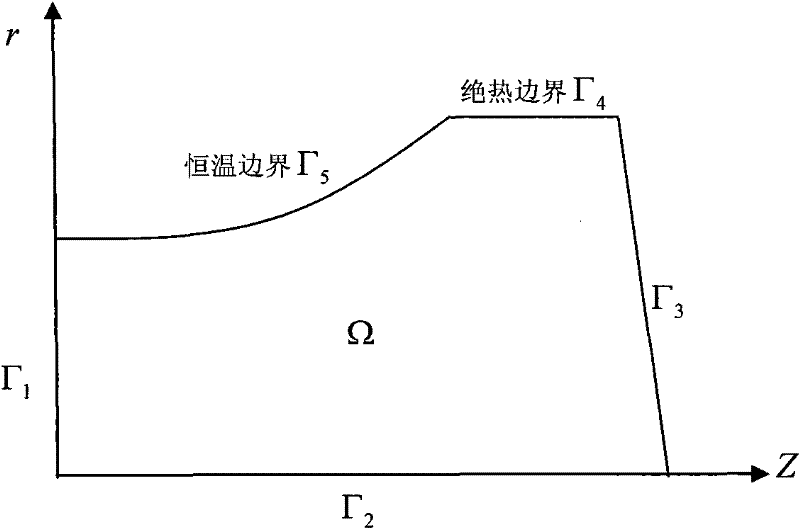

[0021] Hearth Bottom Erosion Analysis and Monitoring System aims to determine the location of the erosion boundary, avoiding the premature appearance of molten iron solidification lines and chemical erosion lines on the carbon bricks, resulting in faster erosion of carbon bricks and ring cracks; Pressing into the furnace will cause thickening of the hearth and affect the smooth running of the blast furnace; it also prevents the shape of the solidification line of molten iron from appearing in the bottom of the furnace in an "inverted pot" shape, forming accumulation in the center of the hearth, and "elephant feet" at the junction of the hearth and the bottom of the furnace At the same time, guide the blast furnace operation, especially the adjustment of cooling water, to ensure that the heat flow intensity of the furnace hearth and furnace bottom is within a suitable range.

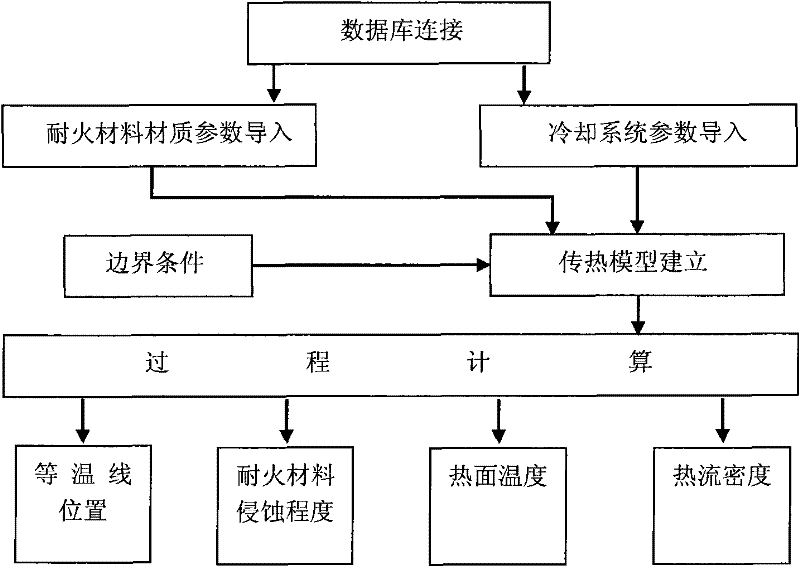

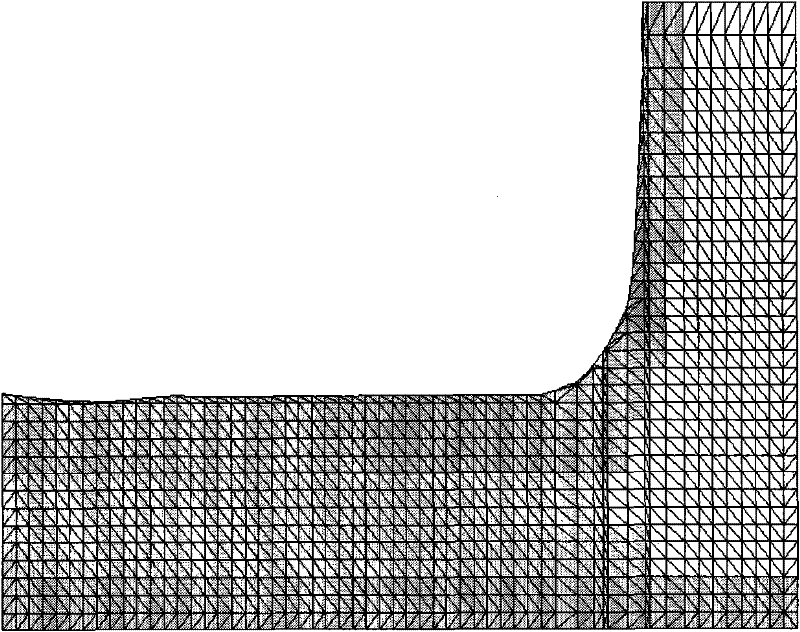

[0022] The principle of the present invention is to judge the corrosion condition of the hearth by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com