Sintering belt cooling pallet and repair method thereof

A technology of sintering belt and cooling table, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc. It can solve the problems of equipment failure, wear of the connecting bottom plates on both sides, and equipment accidents easily, so as to reduce equipment consumption and repair The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

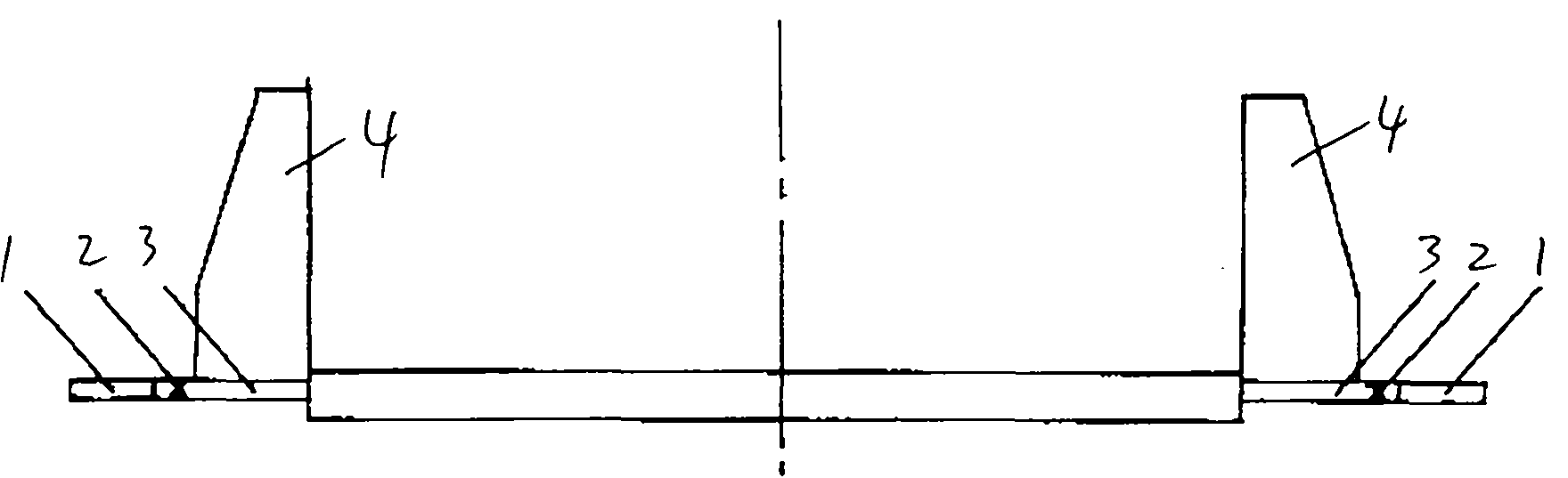

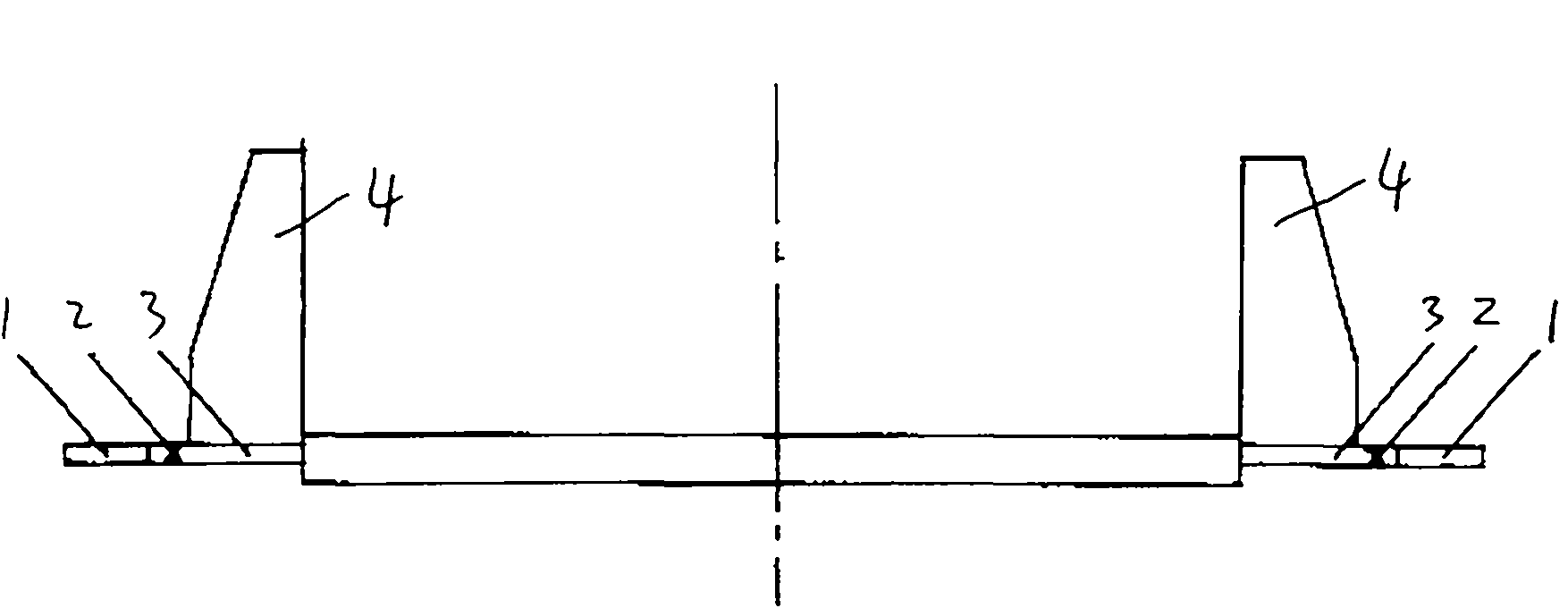

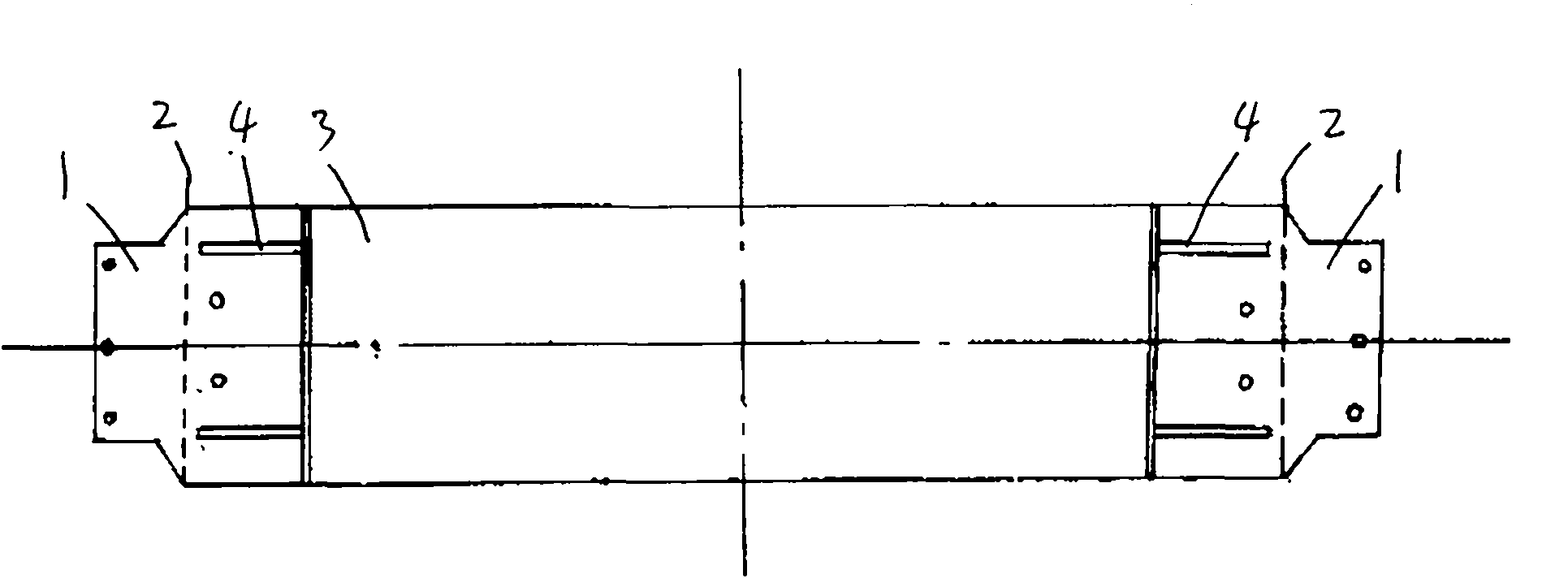

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

[0020] In the sintering belt cooling trolley of the present invention, the bottom plate 3 is provided with two groups of vertical plates 4 opposite to each other. The connection plate 1, the connection plate and the base plate are located on the same plane, and the weld 2 at the right end of the base plate is located on the right side of the right vertical plate, and the weld 2 at the left end of the base plate is located on the left side of the left vertical plate. There is a groove in the front and rear direction on the connecting plate, the depth of the groove is 2mm, and the groove is clad with tungsten carbide alloy which is level with the two sides of the groove. Cladding generally adopts plasma cladding technology.

[0021] The repair method of the sintering belt cooling pallet of the present invention consists of the following steps:

[0022] (1) Cut off the deformed connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com