Natural air dryer of grains

A natural wind and dryer technology, applied in food processing, preservation of seeds by drying, climate change adaptation, etc., can solve the problems of limited application scope, inability to continue, and long operation cycle, and achieve low cost, improve efficiency, Satisfy the effect of large-scale centralized operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

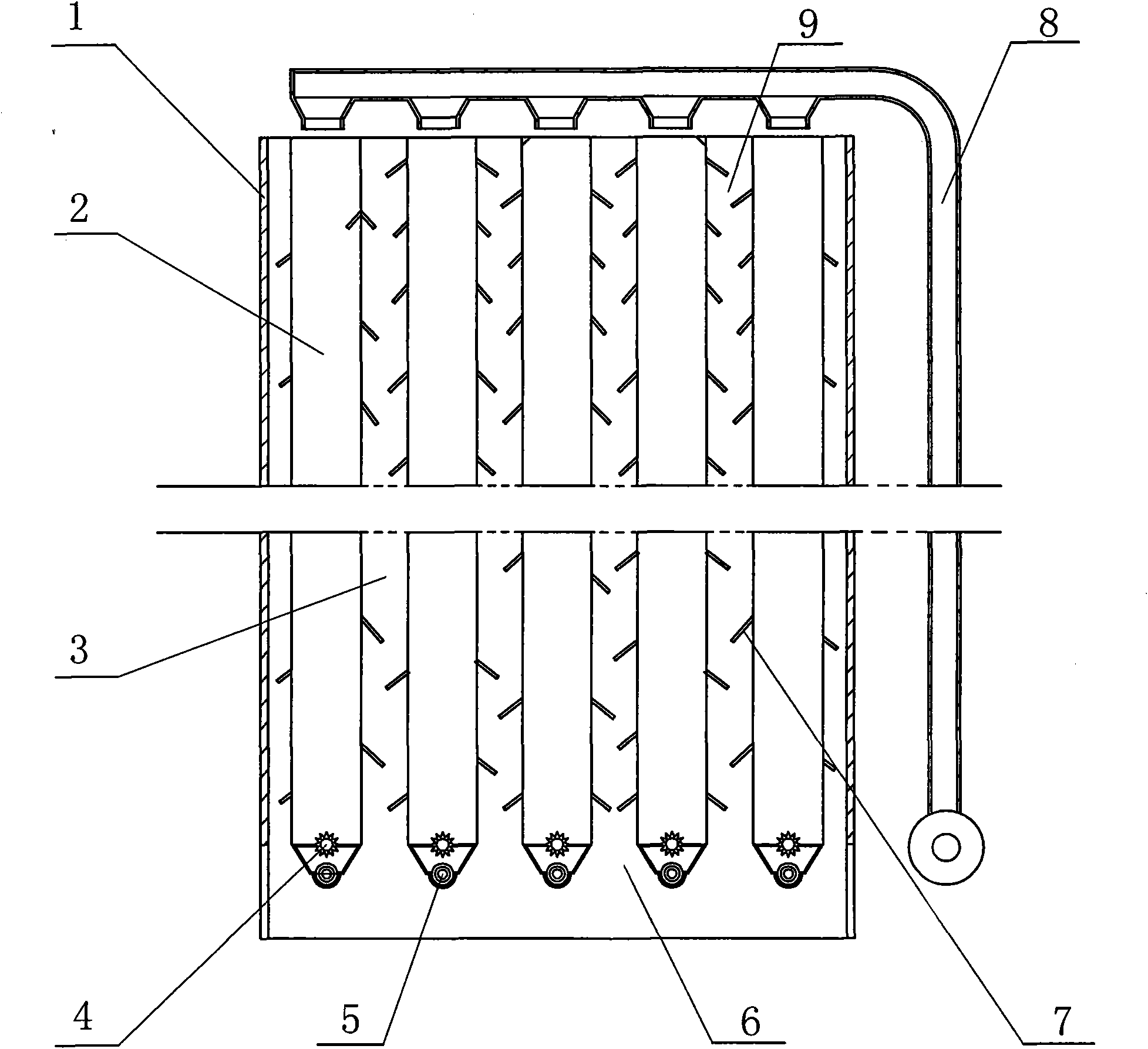

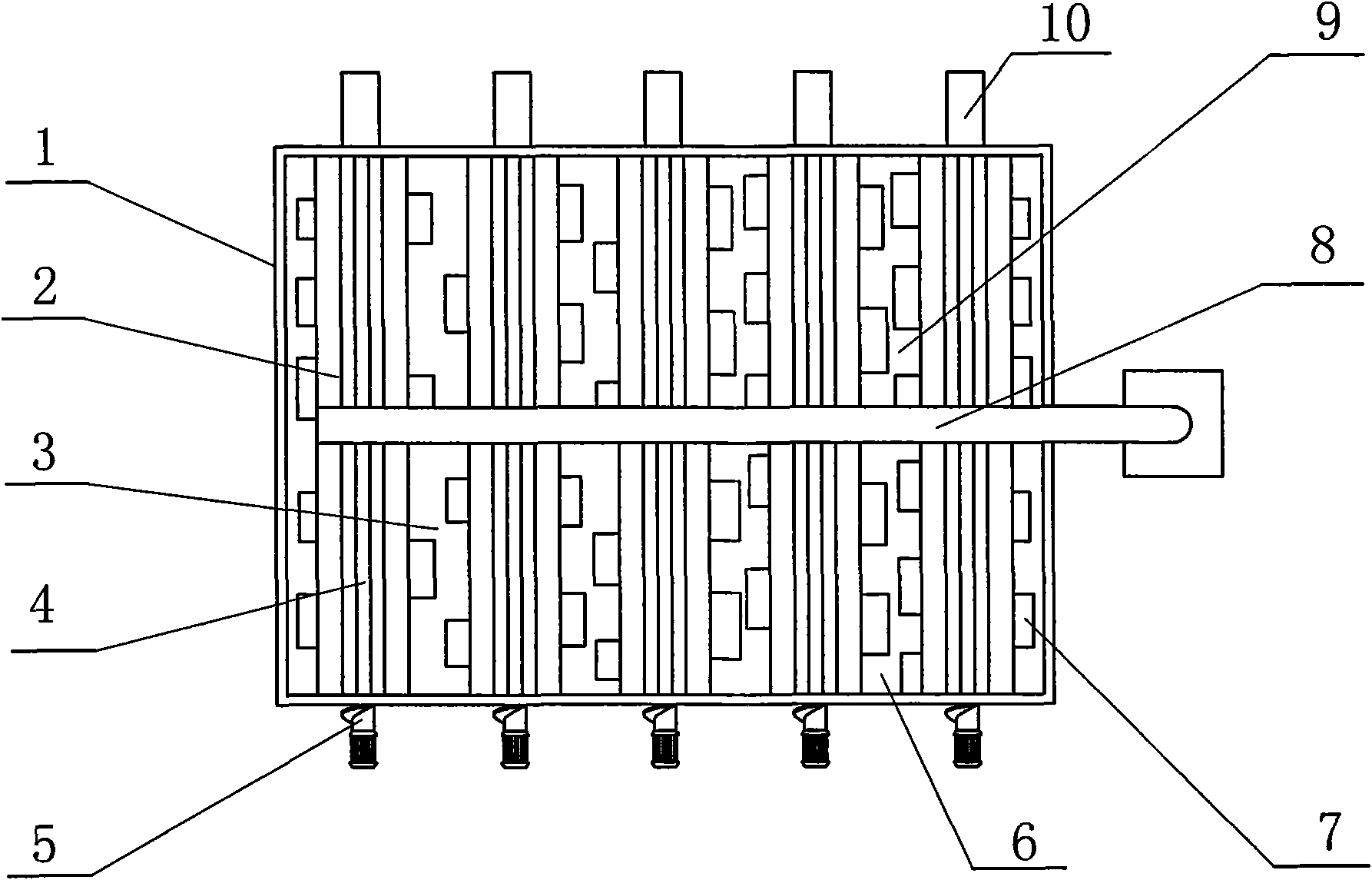

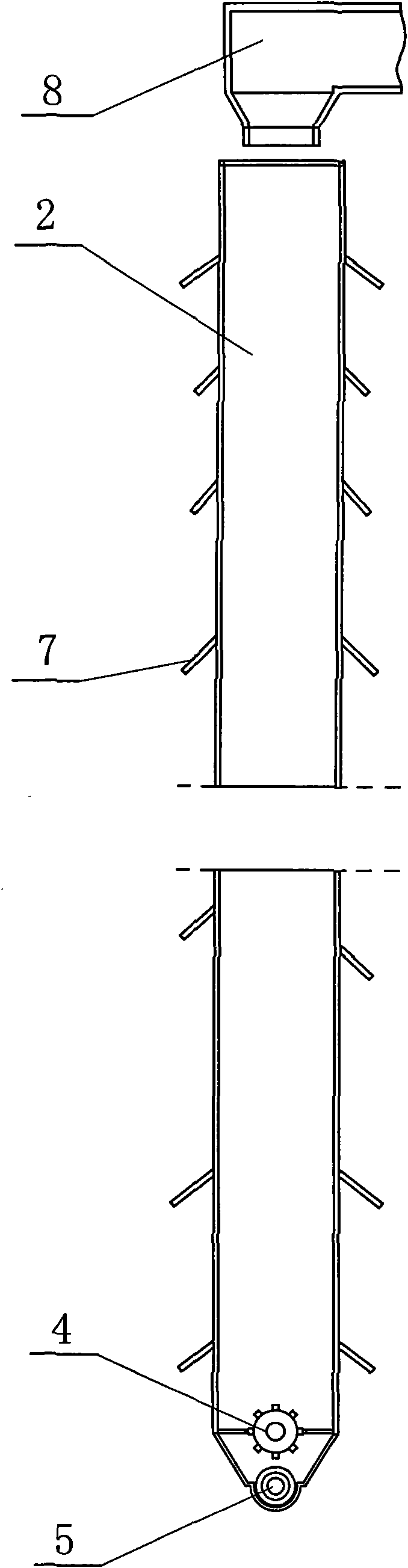

[0022] The first embodiment: as figure 1 , 2 As shown, this air-drying tower 1 is up to 30m, and the tower body is an upright airtight shell with openings up and down. Below is air inlet 6, and above is air outlet 9. A plurality of vertical grain tubes 2 are arranged in the tower. like image 3 , 4 Shown, the cylinder wall of grain cylinder 2 is to be made by screen cloth, and grain can be loaded into grain cylinder 2 by last grain pipe 8. Between the grain cylinders 2 is an air duct 3, and because the wind speed at the top of the tower is high, the airflow in the air duct is driven to go up at a high speed. The outside of the grain cylinder 2 is equipped with a plurality of air deflectors 7, the wind deflectors 7 are installed obliquely downwards, and the angle of inclination is adjustable. Heat exchange with the grain to remove moisture from the grain. Below the grain cylinder 2, a grain discharge device is housed. The discharge device of this example is a grain cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com