Heating device of screw extruder

A screw extruder and heating device technology, applied in the field of heating devices, can solve problems affecting the quality and cost of silk products, uneven tow thickness, large equipment investment, etc., and achieve simple structure, uniform heating temperature, and small equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

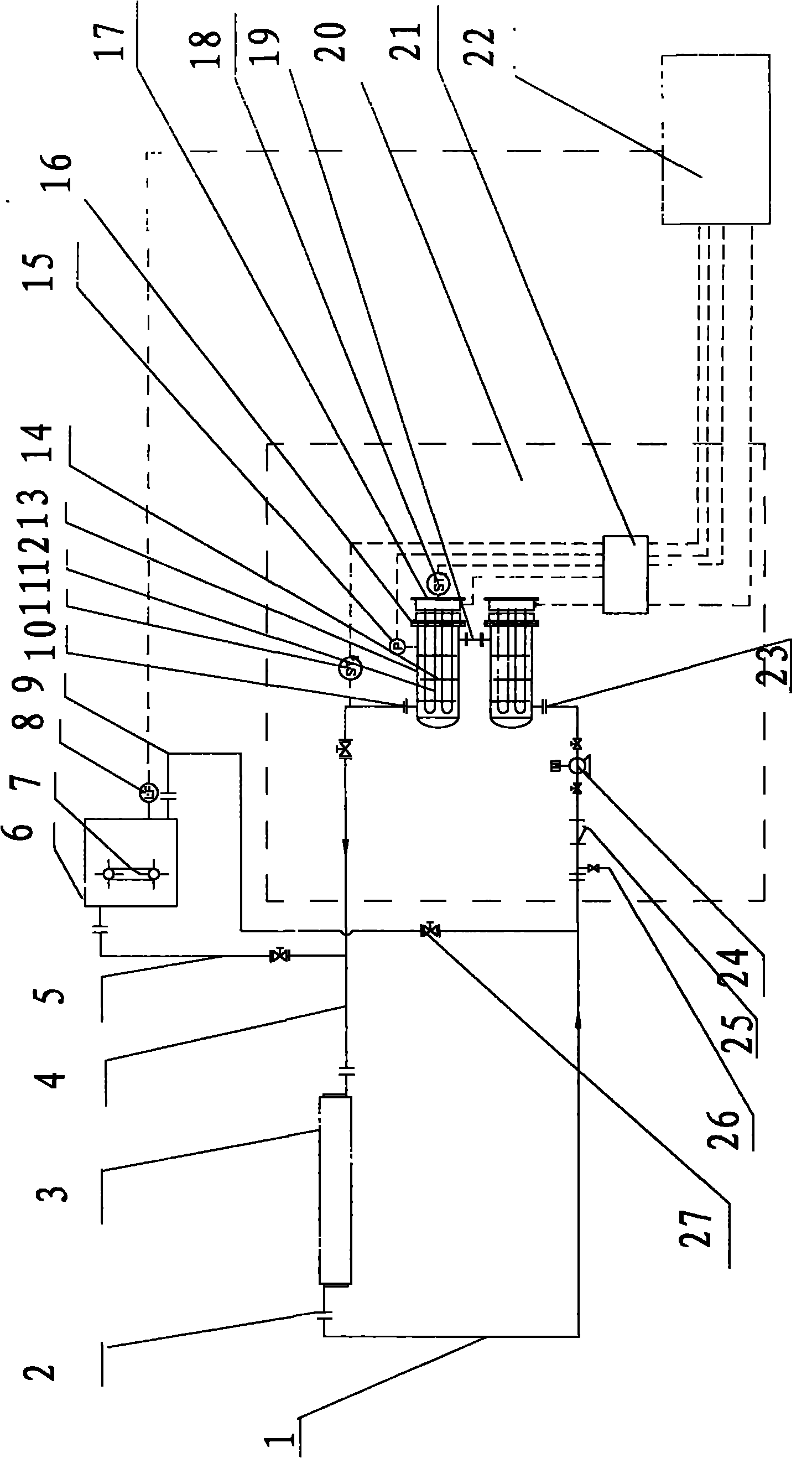

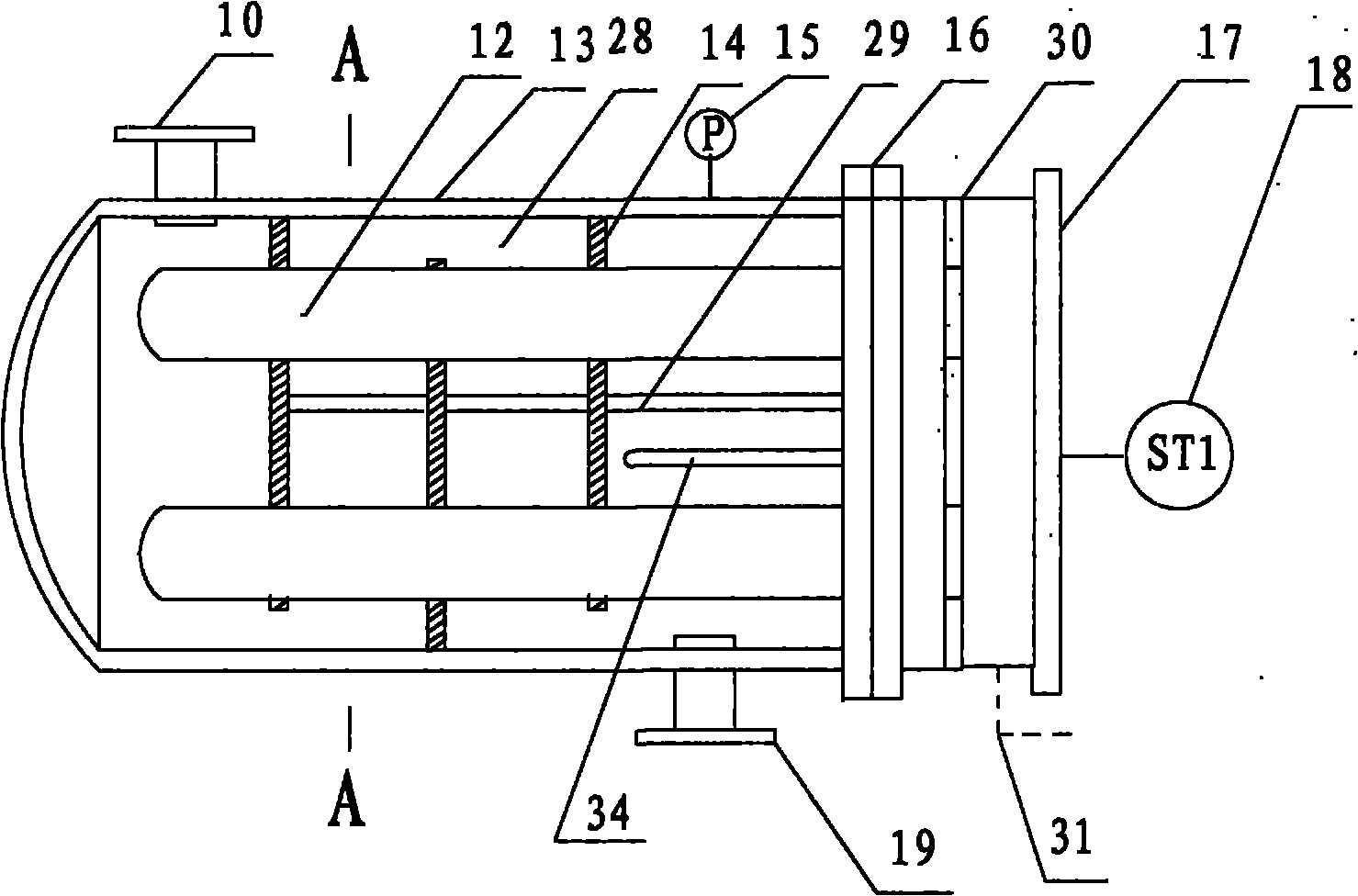

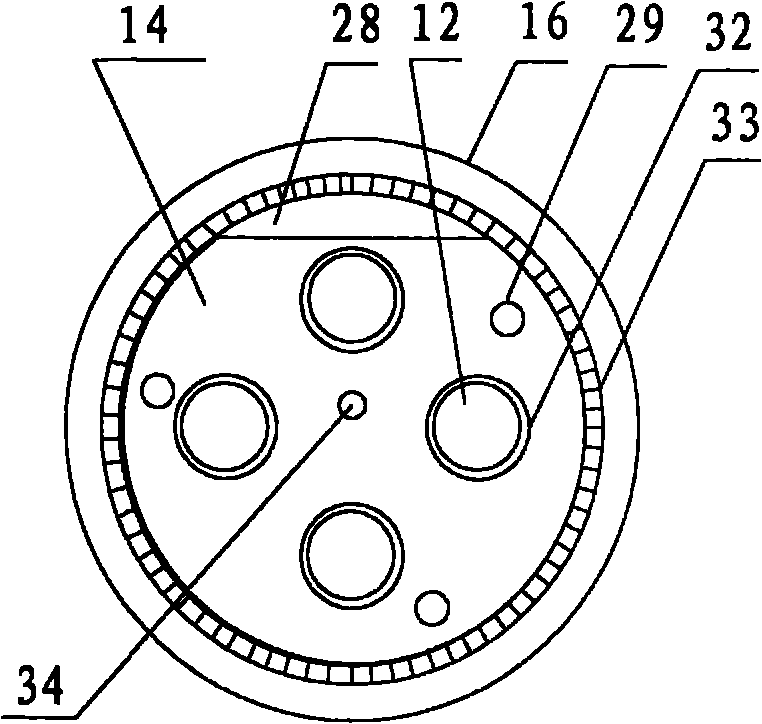

[0015] A screw extruder 3 heating device, including a heat transfer oil body 26 in the fuselage shell interlayer, a pipeline 4, a valve 27, a heat transfer oil heating device 20, and the heat transfer oil heating device 20 includes a heating oil tank 13, an electric heater 12. Thermal oil pump 24 and electrical control system, electric heater 12 and heating oil tank 13 plug flanges 16, 17 are jointed and positioned, and electrical control system connects the temperature sensors 11, 18 and electric contacts inserted in the sensor insertion sleeve 34 The information given by the pressure gauge 15, etc. is controlled by the junction box 21, the control cabinet 22, the heating oil tank 13 is a group connected in series, and a plurality of baffles 14 are arranged in it, which is a large crescent shape, and the electric heater 12 is arranged on it. The socket 32 and the baffle plate 14 are connected by the support rod 29 positioned on the back of the flange 16 and positioned in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com