Ultrasonic sterilizing and algae removing method for industrial circulating cooling water system

A technology of circulating cooling water and ultrasound, applied in the direction of sterilization/microdynamic water/sewage treatment, mechanical oscillation water/sewage treatment, etc., can solve the problems of high power and energy consumption for sterilization, and achieve easy implementation and low energy consumption. The effect of low consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

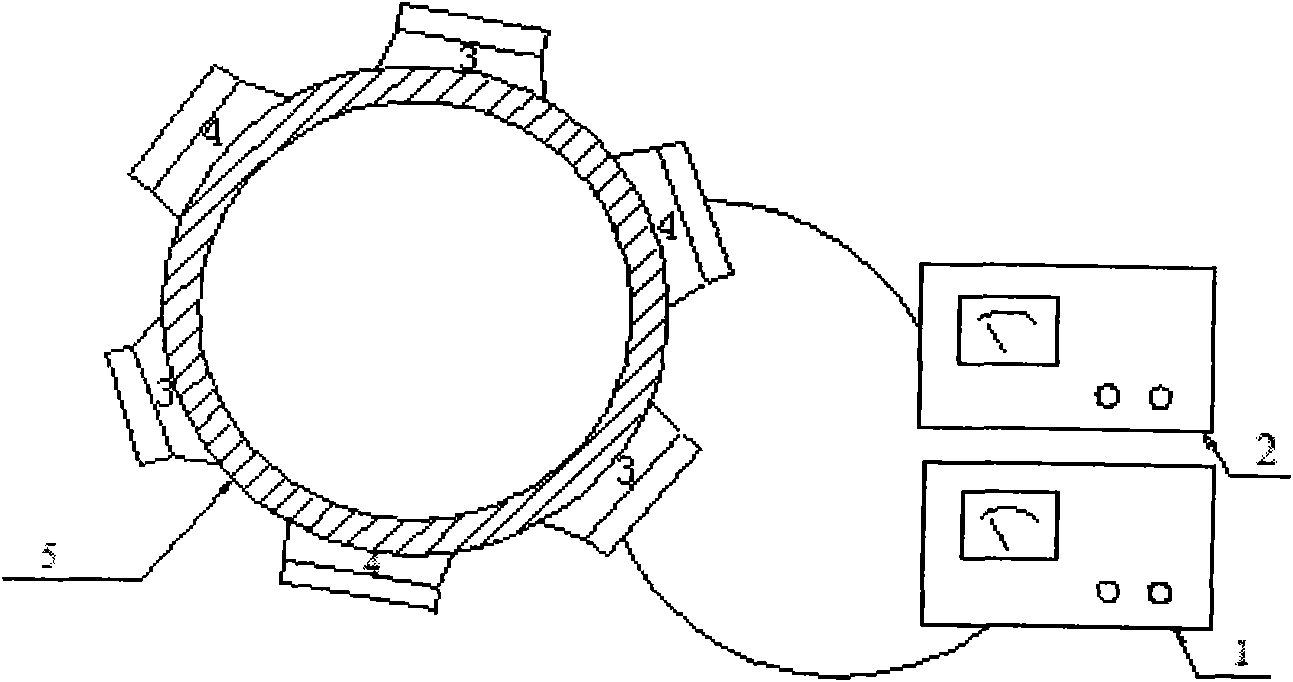

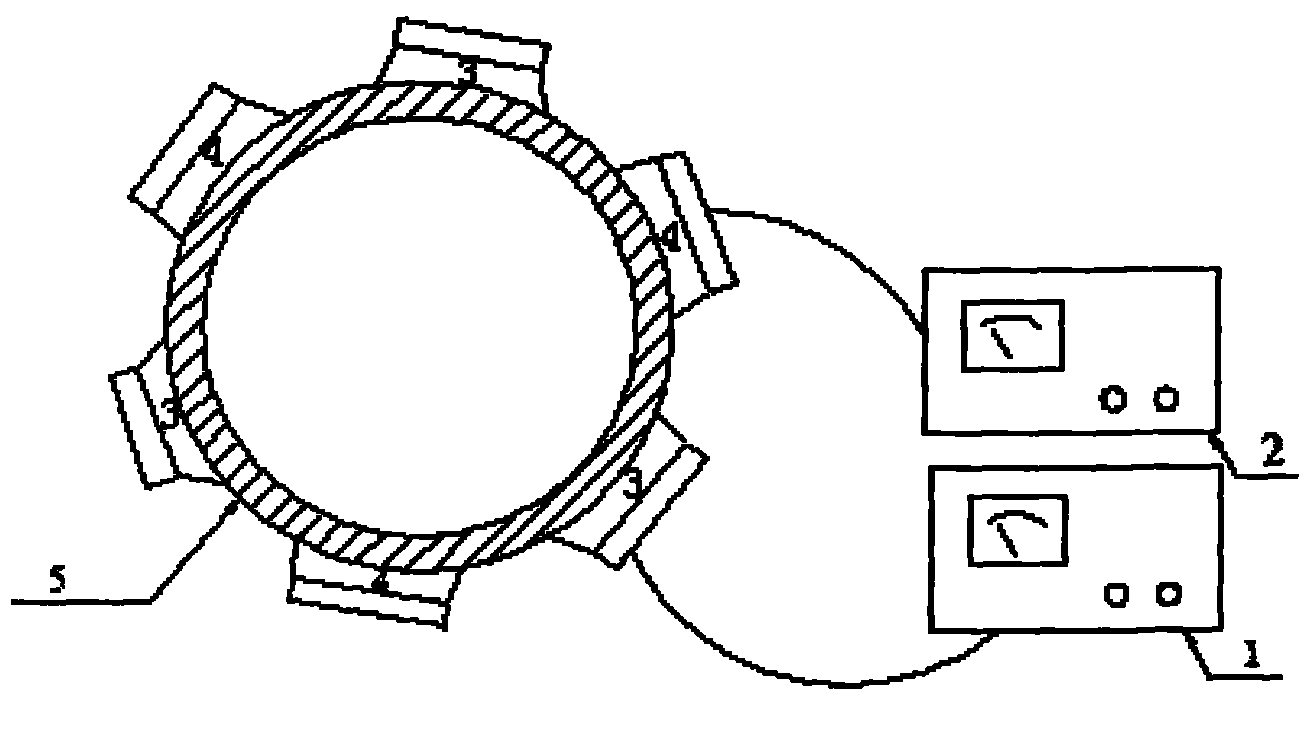

[0025] The industrial circulating cooling water is irradiated for 5 minutes, 10 minutes and 15 minutes through the mixing frequency ultrasonic irradiation device, in which the ultrasonic irradiation device adopts figure 1 The inner diameter of the circulating cooling water pipe is 0.5m, 6 high and low frequency ultrasonic transducers (Wuxi Huaneng Ultrasonic Electronics Co., Ltd.) are alternately and evenly distributed on the outer wall of the pipe, and the flow rate of the circulating water body is 0.01m 3 / min, the ultrasonic frequency used is 20kHz and 1MHz mixed-frequency ultrasonic, and the high-frequency ultrasonic sound intensity is 0.01W cm -2 , the low-frequency ultrasonic sound intensity is 0.9W·cm -2 , and then make a series of dilutions of the irradiated circulating cooling water sample with physiological saline, and then place it in a constant temperature incubator for 36 hours (37° C.), and measure the number of surviving bacteria by plate colony counting method....

Embodiment 2

[0029] The test method and ultrasonic irradiation device adopted are the same as those in Example 1, the ultrasonic frequencies used are 20kHz and 5MHz mixed-frequency ultrasonic, and the high-frequency ultrasonic sound intensity is 0.03W cm -2 , the sound intensity of low-frequency ultrasound is 1W·cm -2 . The results are shown in Table 2.

[0030] Table 2

[0031]

Embodiment 3

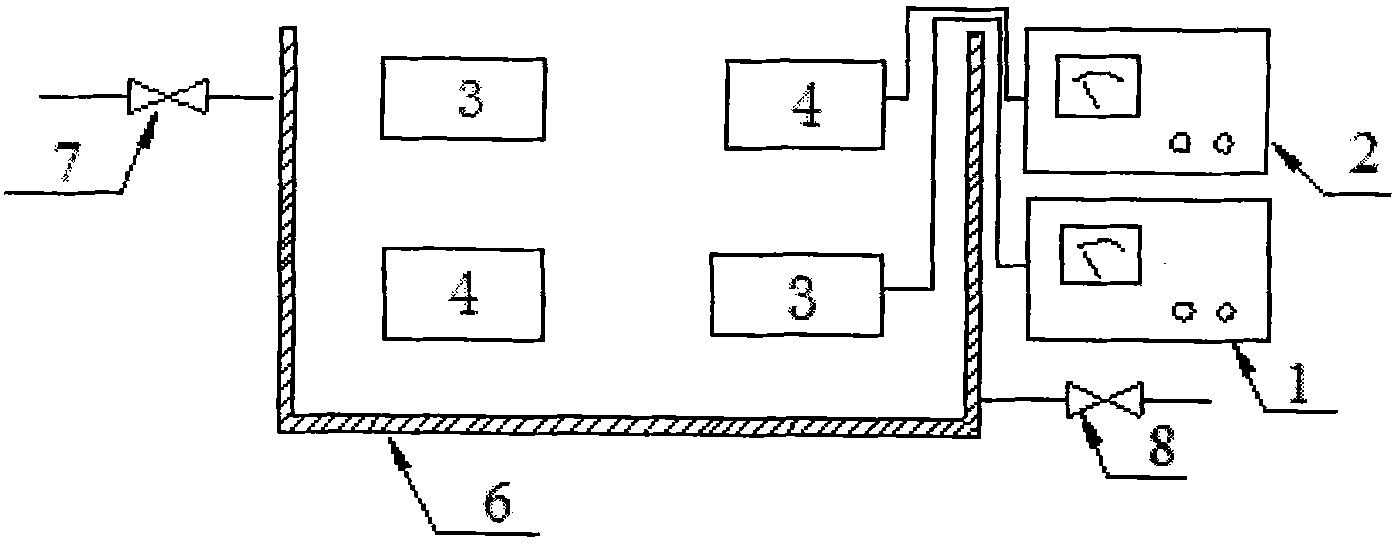

[0033] The test method is the same as in Example 1, and the ultrasonic irradiation device adopts figure 2 form, in which the length and width of the reservoir are 1m, the height is 0.5m, and the water flow rate is 0.03m 3 / min, 8 ultrasonic transducers (Wuxi Huaneng Ultrasonic Electronics Co., Ltd.) are evenly divided into 2 layers (the distribution of the upper and lower layers is the same), and the high and low frequency ultrasonic transducers are alternately and evenly distributed in the circulating water body. The ultrasonic frequency used 40kHz and 5MHz mixed frequency ultrasonic, high frequency ultrasonic sound intensity is 0.07W·cm -2 , the low-frequency ultrasonic sound intensity is 1.2W·cm -2 . The results are shown in Table 3.

[0034] table 3

[0035]

[0036] As can be seen from Tables 1 to 3, the present invention uses frequency-mixing ultrasound for the purification of industrial circulating cooling water systems, which can effectively reduce the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com