System and method for ventilating stacks and collecting exhaust gases and percolate of compost

A technology of leachate and stacking, applied in the field of composting, can solve the problems of disorderly discharge of exhaust gas, easy blockage of pipelines, large engineering volume, etc., and achieve the effect of reducing odor emission, reducing energy consumption and effective collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

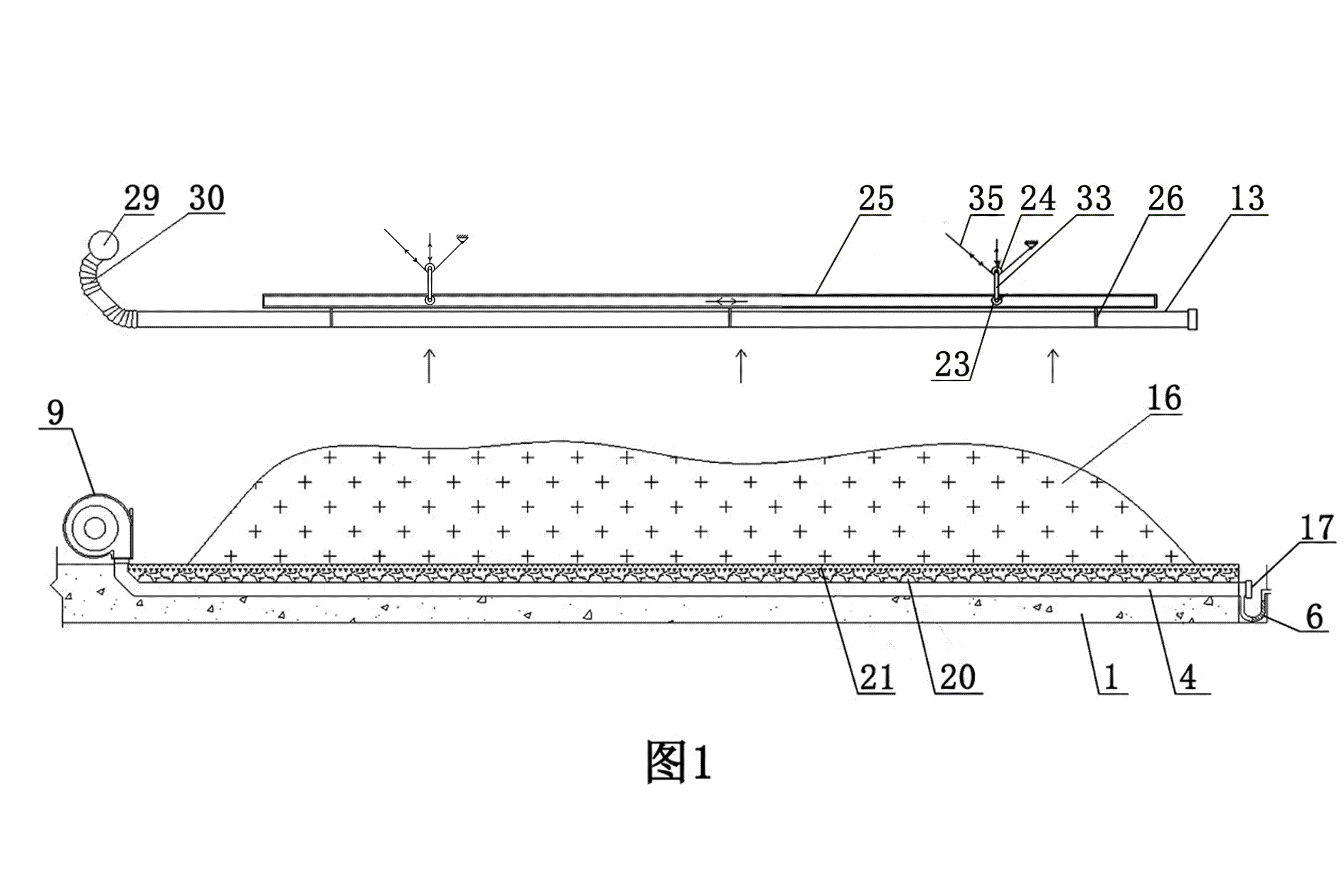

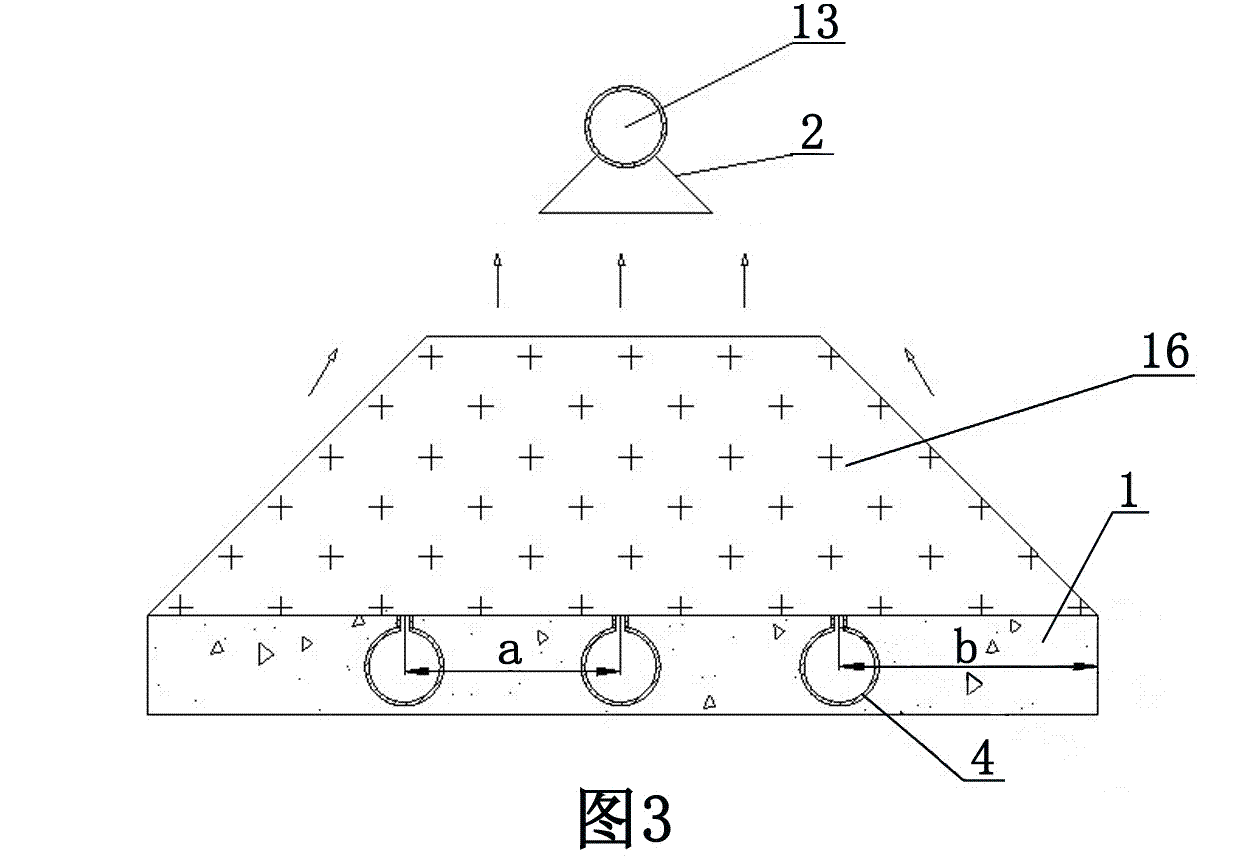

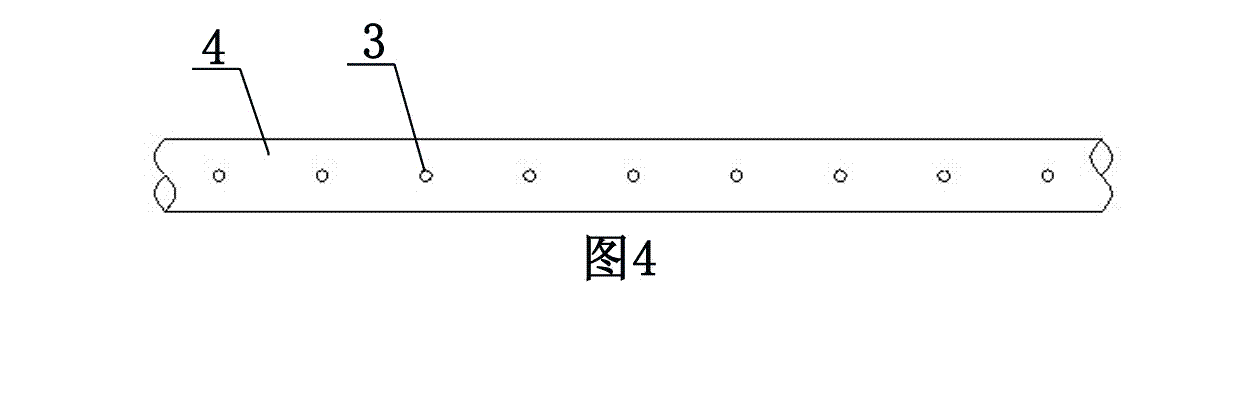

[0063] see figure 1 As shown, the foundation platform 1 is built by impermeable and airtight compressive materials, such as concrete material. In the support foundation 1, the air distribution pipe 4 is laid on the bottom of the compost heap 16, and the ventilation holes 3 are evenly distributed on the air pipe. Pipe 4 is made of anti-corrosion material (such as PVC, steel pipe). Each compost heap corresponds to one or several air distribution pipes. One end of the air distribution pipe is connected with the main air distribution pipe and independently controllable blowing equipment, and the other end It is closed with a pipe plug, and the air distribution pipe is laid in the compact and compressive foundation platform 1. A cleaning tank is left at one end of the pipe plug, and a leachate buffer discharge device is installed in the cleaning tank. Can open pipe plug 17 and open ventilation when foreign matter or leachate infiltrate in the pipe, foreign matter and leachate are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com